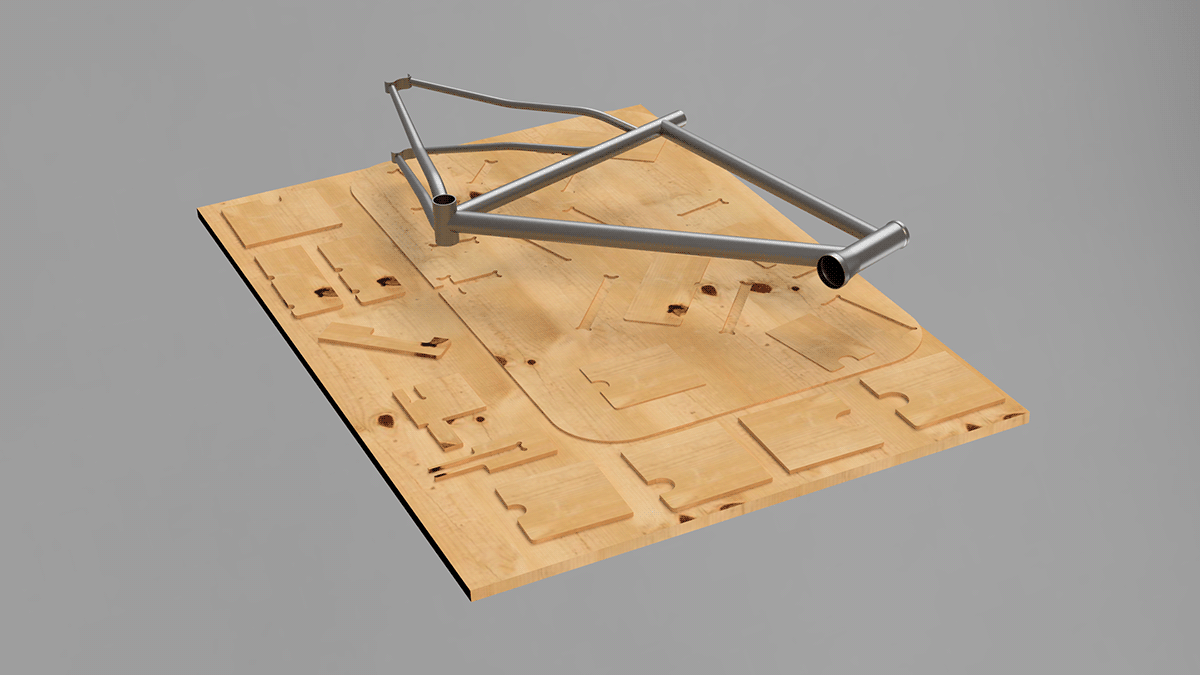

Welding Jig V1

I designed and fabricated it for Bike Builders of Berkeley right after starting the club. As a new club with virtually no funding, we barely had enough money to buy tubes. In order to weld them, our jig would need to be as cheap as possible. I found a large piece of mdf wood at Jacobs hall, it was abandoned and so free to me.

With the constraint of materials and cost, the design was rather straight forward. In order to prevent fires and facilitate welding, all the stand-offs needed to be distanced from welding points.

After designing the frame in Fusion 360, I added the wood below it and made extrusions into the frame to cradle it. Using the combine/cut tool, all of the extrusions were perfectly notched. The final step was to lay the stand-offs flat and then cut them out!

the layout for cutting the jig

the welding jig also served as a guide for cutting and coping the tubes. By placing a tube in and marking it, we could cut/file/grind the correct shape. It was a tedious process, but with help from Jacob Pashman we finished cutting and welding in one day!