UC Berkeley Engineering Showcase

These are a few of the projects I worked on while getting my BS in Mechanical Engineering from UC Berkeley.

DARPA MBARC Amphibious Vehicle Challenge

Goal: create a vehicle capable of traveling quickly through water and on land. We took apart an advanced RC car, created a styrofoam shell, put them back together, added motors, propellors, and batteries, and waterproofed the contraption. We then raced against MIT and Vanderbilt at the Marine Corp Base Camp Pendleton in San Diego.

Codename: The Cooler. Waterproofing the axles was the hardest part.

It had some kick to it, though.

Okay, so perhaps there were several "hardest parts."

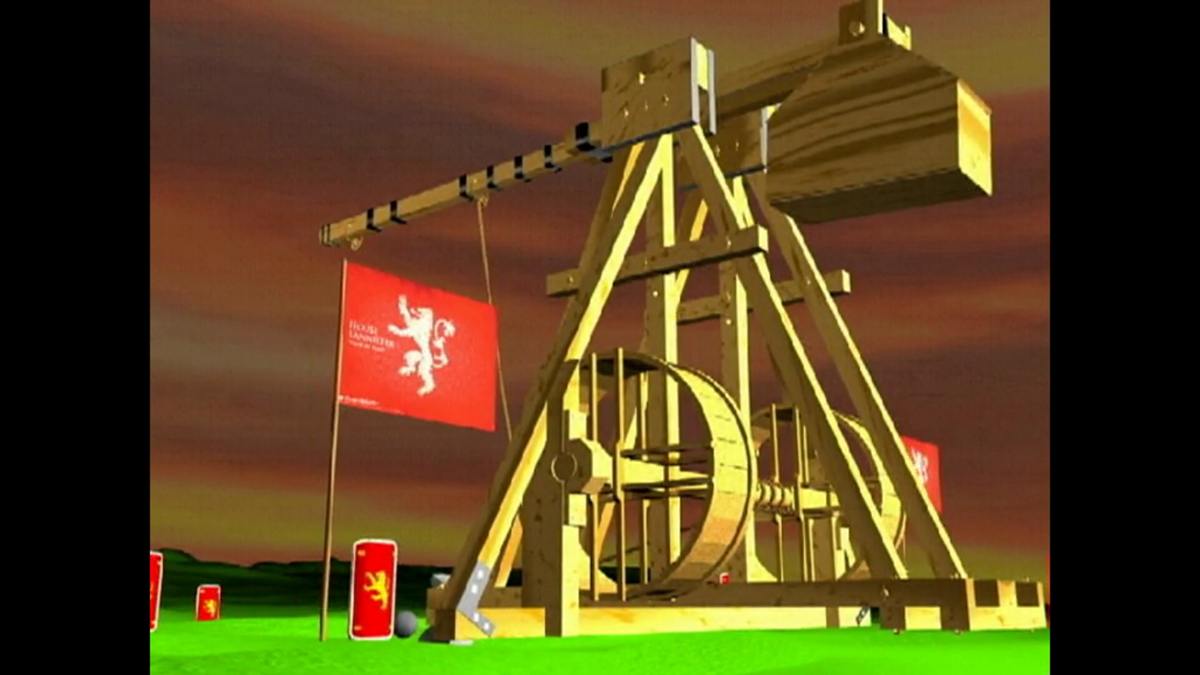

Advanced Engineering Design and Graphics

Goal: use Creo and 3D Studio Max to create and animate digital models. In this case, the Warwick Trebuchet, the largest functional trebuchet on Earth, and a P-38 "Lightning" WWII fighter plane.

Pictured: the fruits of many sleepless weeks in the Etcheverry computer labs.

Some of George Martin's characters would love to get their hands on one of these.

Getting realistic materials and textures is very challenging.

"The Flying Fox"

Rapid Prototyping

Goal: gain experience with several methods of rapid prototyping, including 3D printing, water jetting, and CNC milling.

Our 3D printed robot. Turn a crank on his back and the arms will spin!

We designed it in Solidworks and set the program, then the CNC mill did the labor for us.

Did you know water can cut through a sheet of 1/4" thick aluminum? The process has to be done underwater or it would be louder than a jet engine.

Finite Element Analysis

Goal: simulate the wind flow over a turbine using Solidworks and other software.

This one was mostly math.

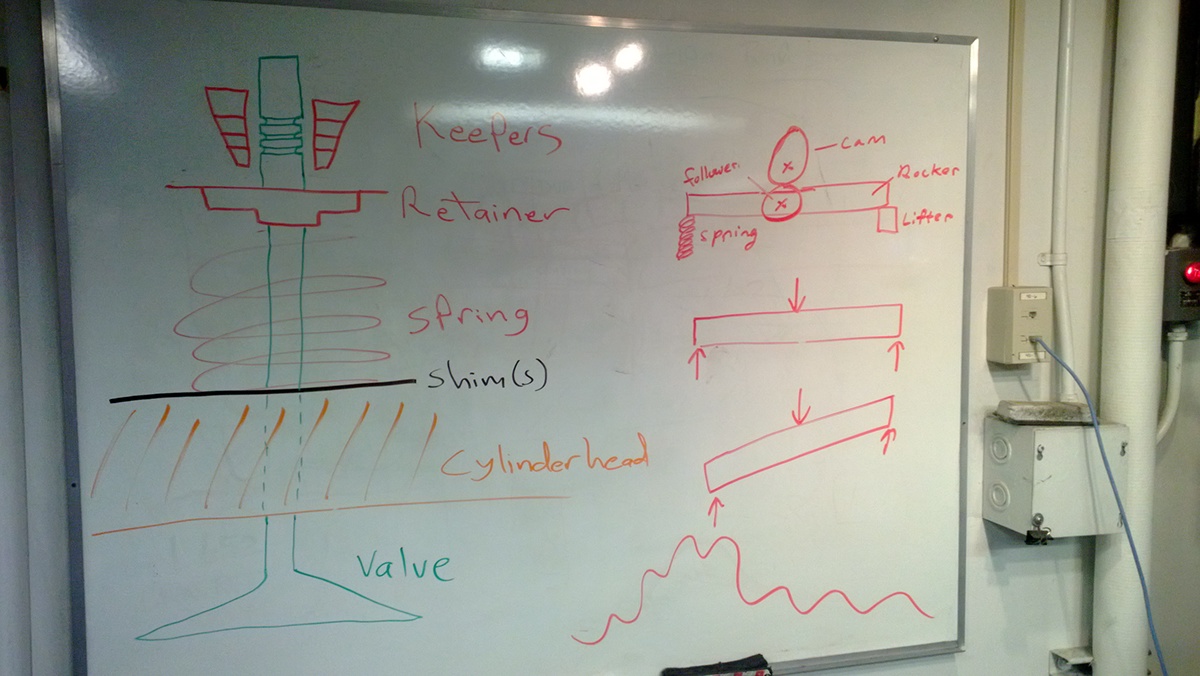

Experiment Design

Goal: learn the proper way to prepare, run, and analyze data from laboratory experiments. In this case: the optimum angle to wear a hat against the wind, and effects of various combinations of springs, shims, and dampeners on valve float and spring surge in a 4-cylinder engine.

Turns out: if you're straight on to the wind, a flat-brimmed, horizontal cap will stay on in the highest wind speeds. If you're at an angle, you'll want a curved brim, tipped about 10 degrees up from horizontal.

Sometimes, science is greasy.

Whiteboards are mandatory for proper science.

Mechatronics Design and Experimentation

Goal: learn some advanced techniques for creating and testing mechanisms. Each of the below mechanisms was 3D printed and stress tested.

Our design for a base-relief of Berkeley's Campanile. It was tested by applying 20N to the central plate and measuring the resulting deformation.

A rectangular chassis. We designed it to withstrand both force and torque.

A four-bar mechanism (the fourth being the pegs we attached it to), built to maximize accuracy and repeatability of its arc when moved back and forth.

Labview: can't live with it, can't gather data without it.

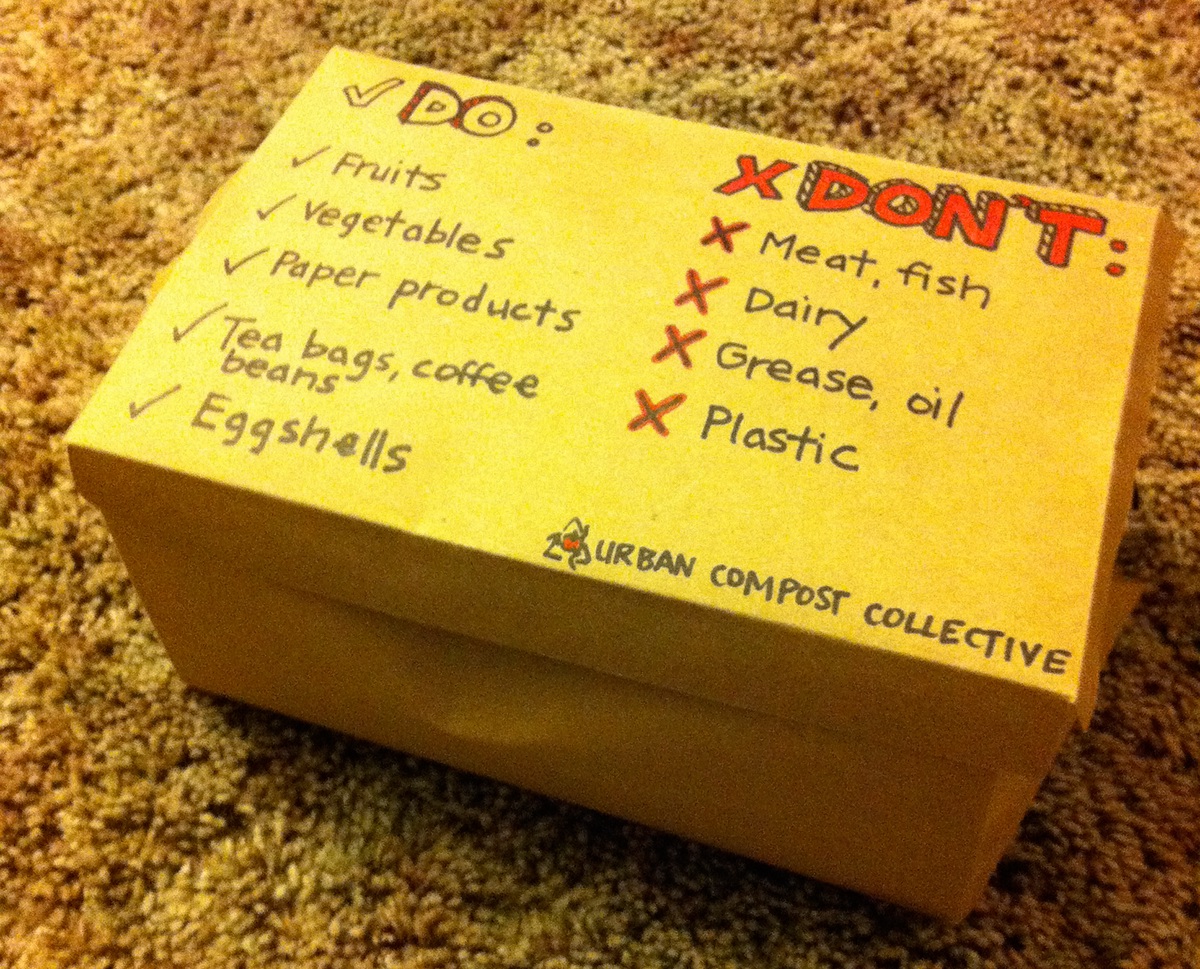

Product Design - Compact Composting

Goal: create a product, from initial needfinding and benchmarking, through prototyping and design iteration, to lifecycle analysis and sales pitch. In our case, Compact Composting - a system to enable those living in apartments and urban homes to compost their organic trash.

The last prototype we made. The box itself was simple - it was the supply chain and sales pitch that was hard.

Some initial concept sketches of what a "friendly" composting box could look like.

One of our imagined business models involved getting children, teachers, and classrooms involved.