PROJECT

Excessive efficiency oriented manufacturing method inevitably causes massive waste.

Excessive efficiency oriented manufacturing method inevitably causes massive waste.

ZERO PER PROJECT as an alternative of this contradict concept, has sought for “how to make a chair” in a new way.

PRODUCT

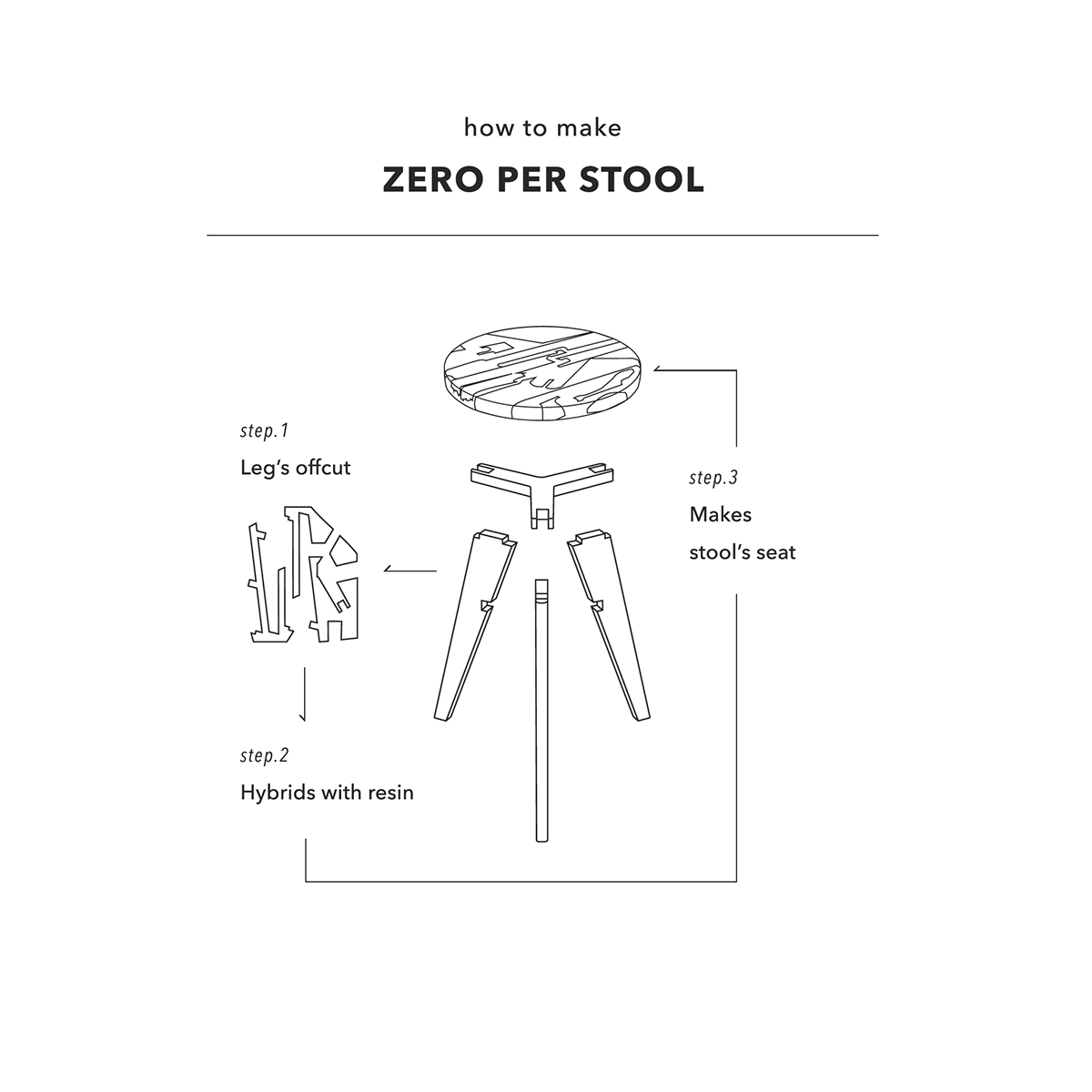

It is the output after devising a production method which does not generate offcuts using hybrid wood technique.

(Hybrid wood technique is to solidify cured resin with cracked wood pieces after pouring into a mold. These materials are recreated into various forms of products such as fountain pen, stamp using handwork. The translucent resin is to exhibit the shape of abandoned woods plainly as well as is to be stuffed the pieces of wood.)

Zero per stool is consisted of two parts which are the legs with White Oak collection tree and the upper board with application of hybrid wood technique. The offcuts from the legs are solidified with cured resin and reformed to the upper board as the essential structure of the stool. The waste produced from the product is reduced to almost 0%.

Every stools are produced after flattening and placing the leftover woods and they are the only one product with different compositions and characteristics. The interesting shape of woods and various colored combinations of the translucent resin are presented new aesthetic beauty to the consumers.

thank you!