X-MAS * ⁎ ⁑ Laser-cutting wooden toys

激光切割的木制玩具

Laser-cutting plywood allows you to make the elements without mechanical stress on the material, so the appearance of chips or lint on the edge of the material is completely excluded. The diameter of the laser beam is so small that it makes it possible to cut items with a few millimeters in size.

激光切割胶合板允许你在不对材料产生机械应力的情况下制作元件,所以完全排除了材料边缘出现的碎片或毛刺。激光束的直径非常小,使得它可以切割尺寸为几毫米的物品和复杂的几何形状。

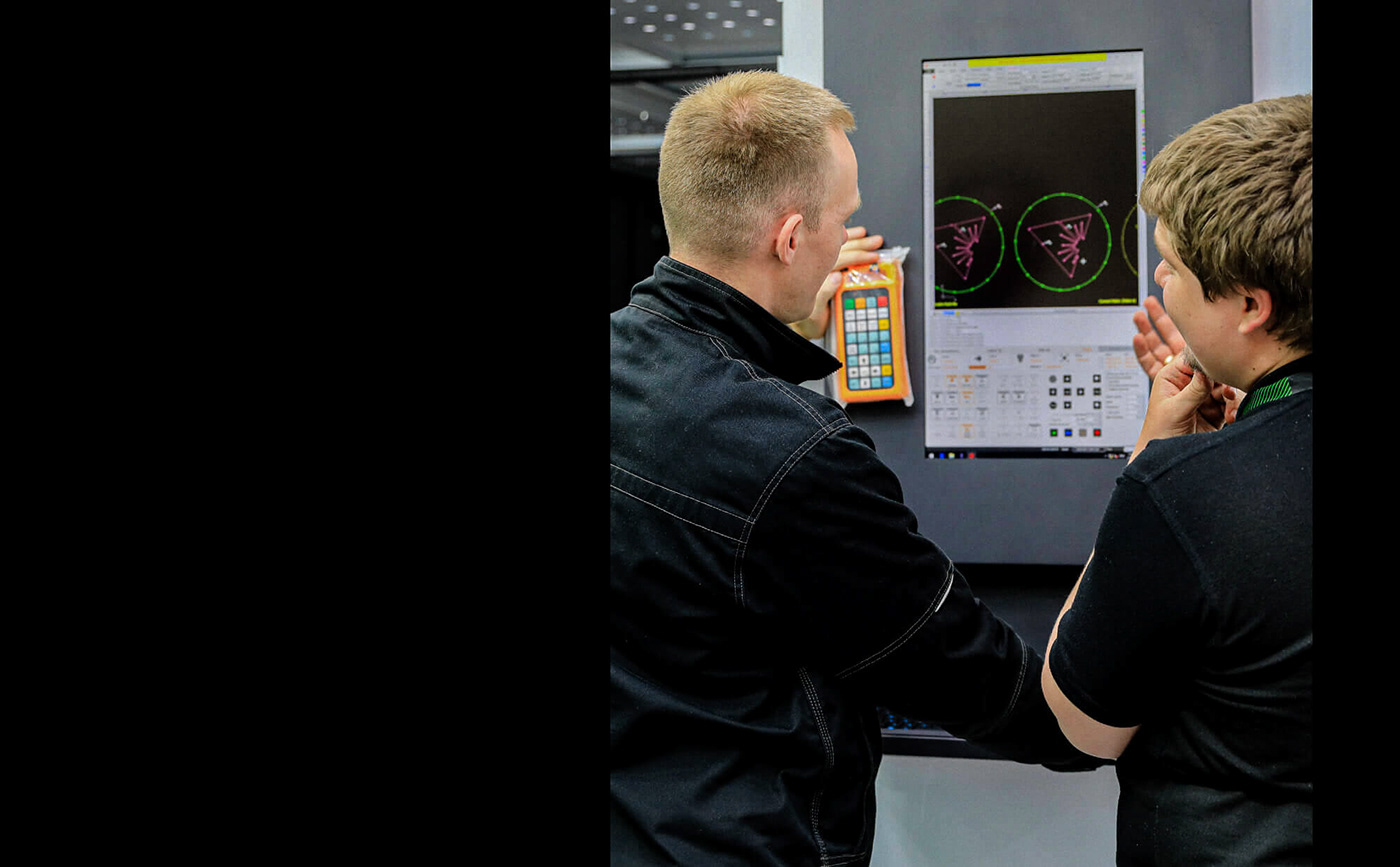

The work is performed using a special CNC machine. The equipment is equipped with a light source - a laser, which is concentrated in a single beam and is able to pierce holes in hard materials. The laser beams cut the surface of the plywood sheets and a drawing or product corresponding to the layout is obtained.

这项工作是使用一种特殊的数控机床进行的。该设备配备了一个光源--激光,它集中在一个光束中,能够在硬质材料上打洞。激光束切割胶合板的表面,获得与布局相对应的图纸或产品。

Plywood is an excellent choice in decorative projects. The unique bonded veneer design allows plywood to retain the natural beauty of wood, but be a more durable and less expensive solution than wood itself.

胶合板是在许多装饰和其他项目中使用的绝佳选择。

独特的粘合单板设计使胶合板保留了木材的自然美,但又是比木材本身更耐用、更便宜的解决方案。

独特的粘合单板设计使胶合板保留了木材的自然美,但又是比木材本身更耐用、更便宜的解决方案。

The main difference between the laser and the cutter is the accuracy in cutting corners, the speed and low cost of the work. The laser beam is much more maneuverable than metal cutters and mills, due to which the optimal correspondence of the cut material to the drawing is achieved

激光和切割机的主要区别在于切角的准确性、工作的速度和低成本。激光束比金属切割机和铣床的可操作性强得多,正因为如此,才能实现切割材料与图纸的最佳对应。

When choosing material, preference should be given to varieties of wood sheets

with low resin content, as their presence complicates the work.

with low resin content, as their presence complicates the work.

在选择材料时,应优先考虑树脂含量低的木板品种,因为它们的存在使工作变得复杂。

The image below shows how the cut on the product is obtained when laser cutting plywood. The edge on the workpiece has changed color. The darkened edge of the plywood emphasizes the contours of the product.

下图显示了激光切割胶合板时,产品上的切口是如何获得的。工件上的边缘已经改变了颜色。胶合板的边缘变深,强调了产品的轮廓。

The maximum thickness of plywood which can be cut through by the laser beam depends on the power of the laser transmitter and is often limited to 15-20 mm. The cut after laser cutting changes its color (burns).

激光束能切穿的胶合板的最大厚度取决于激光发射器的功率,通常限制在15-20毫米。激光切割后的切口会改变其颜色(烧焦)。

Cutting plywood with a laser has a number of features and advantages. Among the features is the darkening effect at the point of contact between the laser beam and the surface of the plywood. It is often used when creating interior décor. If necessary, it can be quickly and easily eliminated with lacquering liquids.

用激光切割胶合板有很多特点和优势。其中的特点是在激光束和胶合板表面的接触点上有变暗的效果。在制作室内装饰时,经常使用这种效果。如果有必要,可以用涂漆液快速、方便地消除。

It is worth noting that not only do the methods of cutting plywood differ, but also its characteristics. Plywood can be made of birch veneer or softwood veneer, its surface is sanded and not sanded. It also differs in thickness, moisture resistance, the type of gluing material, the presence or absence of defects on the surface.

值得注意的是,不仅切割胶合板的方法不同,其特点也不同。胶合板可以由桦木单板或软木单板制成,其表面经过打磨和不经过打磨。它在厚度、防潮性、胶合材料的类型、表面有无缺陷等方面也有不同。

The laser beam works well on plywood sheets, but the plywood must be of high quality. The cutting result depends on the raw material and the type of adhesive. It is better to laser cut desmixed coniferous plywood. If you work with larch, the surface will be charred. Birch plywood sheets are less amenable to processing, as dark edges are formed.

激光束在胶合板上效果很好,但胶合板必须是高质量的。切割效果取决于原材料和粘合剂的类型。最好用激光切割脱混针叶树胶合板。如果你用落叶松加工,表面会被烧焦。桦木胶合板的加工效果较差,因为会形成黑边。