GALVANIZE

galVANize rethinks the process of using recycled materials to achieve sustainable design. The most sustainable material is the one that has already been created. What if designers, instead of calling on new materials for their designs, scoured their milieu for already existing materials that fit their needs? Traditionally, recycled building materials must be located, moved, melted down and finally fabricated into useable components. galVANize

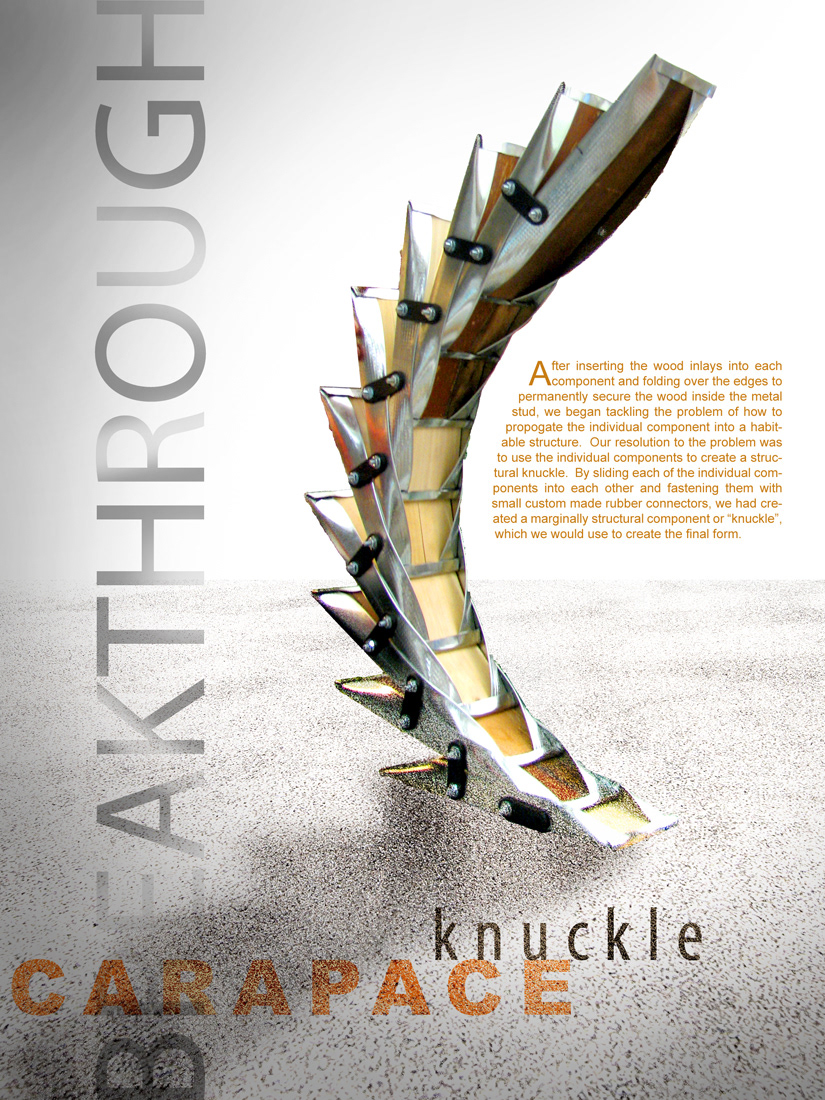

Problematically, the agreed upon qualities the team desired were surprisingly non-structural. The serrations that created the beautiful floral qualities also made the steel studs phenomenally weak to load in any orientation. So, the team decided to try another series of material investigations attempting to keep the valued qualities of the steel, while also increasing its structural potential.

Finally, the component was finalized. We had now devised a means of making the individual component (above) into a habitable space. The component would be fit inside of itself repeatedly creating a "knuckle". This knuckle was joined up with other components of varying lengths to create a "rib". Using scripting the team investigated a form that would be structural up to 12' tall and also be aesthetically pleasing.

The final GALVANIZE installation was build to full-scale. It's dimensions were approximately 12' x 5' and was 8' tall. Above are the inputs used to fabricate the final installation for the Fragments and Refinements Exhibit.