TMC Labs (Think, Make, Create)

Mobile Maker Space 2019

Introduction

TMC Labs are designed to be a low-cost entry point for Nebraska youth to tinker, explore and problem-solve while helping to promote long-term sustainability for rural afterschool and summer programs.

Design

My objective for the design of TMC Labs was to create an open source platform for any after school program or community to develop and build their very own Mobile Maker Space. The interior build out needed to be simple enough for a highschool shop class to assemble. The CNC parts needed to be extremely durable to last for many years. Lastly, keeping the price as low as possible made TMC Labs accessible for all communities. The build out cost was around $500 total.

In Use

We currently are licensing TMC Labs statewide. Wyoming and Louisiana have been the first states to successfully build their own and use at after school program sites. In Nebraska alone, there are a total of 23+ TMC Labs!

Process

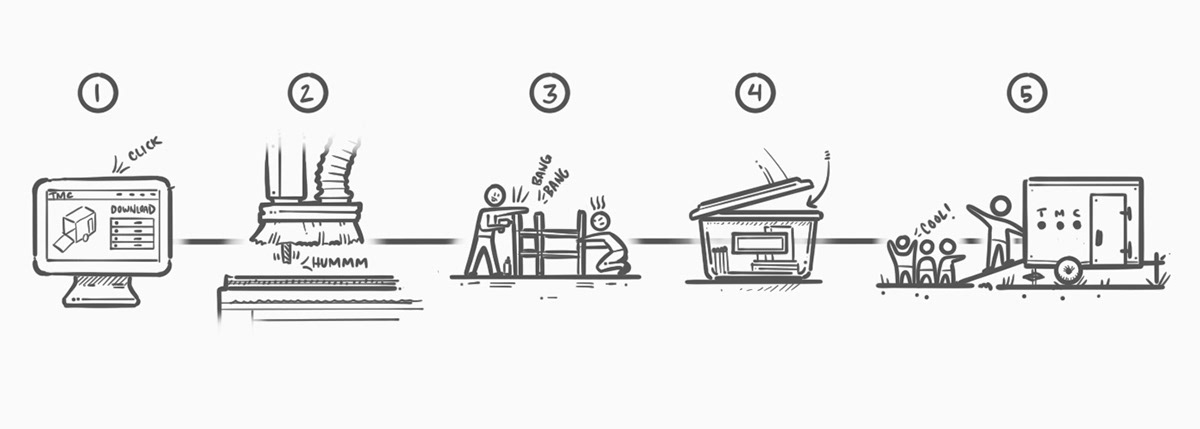

Below you will see steps 1-5 to complete a TMC Lab. I have created many resources which you will find in the links below that aid communities in developing their own. These resources include Google Site, DXF Files, "How-to Videos," and more.

1. Download CNC files from Website.............................................Click here to see website

2. CNC Parts..............................................................................Click here to see build plans

3. High School Students Assemble Parts............................Click here to see "how to videos"

4. Load TMC with Materials/Tools............................................................................See below

5. After School Program Receives TMC Lab!...........................................................See below

Design & Build Process

Afterschool sites throughout Nebraska using TMC Labs highlighted the need for adaptable storage spaces and easier to assemble parts.

I also wanted to use less plywood for the design which helps to cut down on CNC time.

The sliding wall uses casters that fit into a plywood rail attached to the floor. There are slots in the rail that are used to lock the wall in place using the hockey stick stop" pictured above.

These slide out drawers use no hardware to keep the overall cost low. Instead, the drawers slide on cleats, pictured below. To keep them secure while the trailer is being moved the front faces of the drawers drop into a notch in the cleat.