Ice cream cone made for Metals II Final. The assignment consisted on designing a metal piece that would require us to employ most (if not everything) we had learnt throughout the semester.

For this project I chose to make an ice cream cone because it allowed me to use the lathe to taper, cut in a radius, plane, face off, drill, bore, and part. I also used the Bridgeport vertical mill in order to make small cuts for the details on the cone.

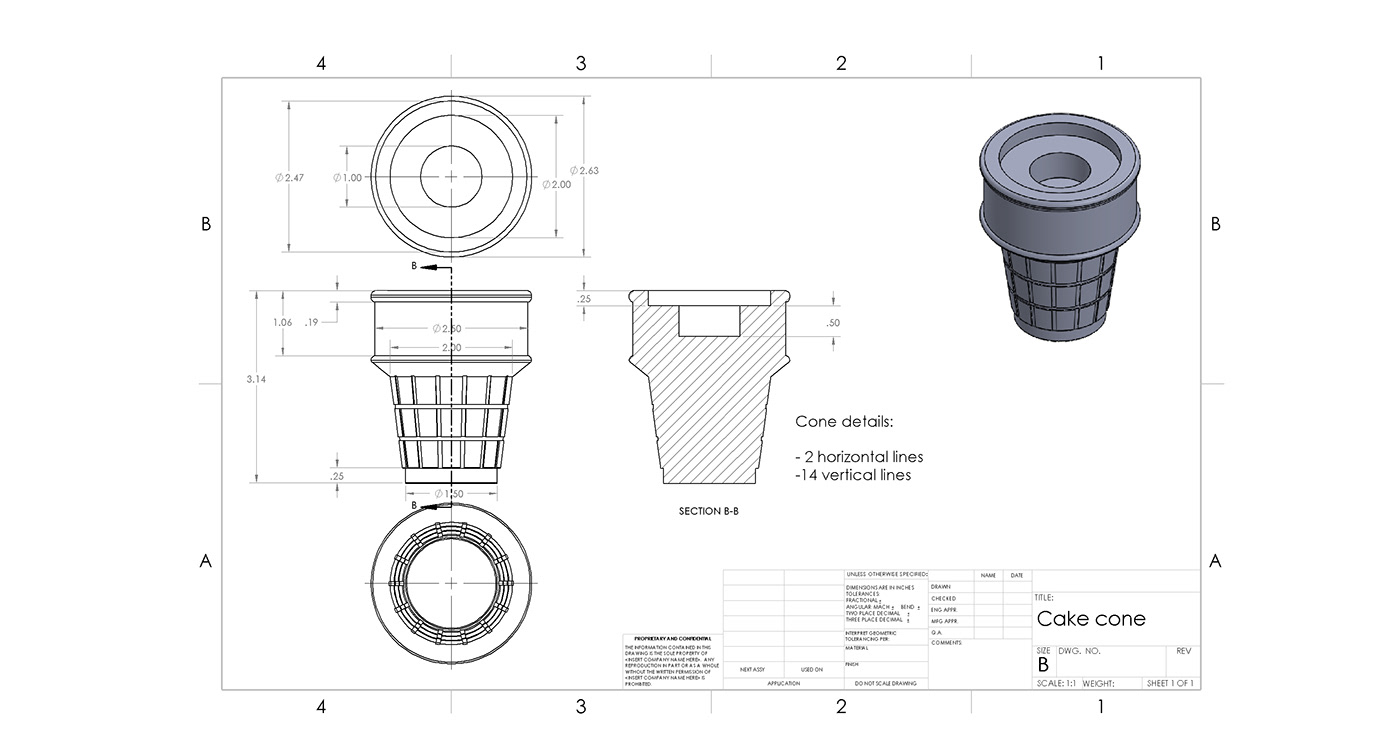

I started by making Solidworks models and drawings of my designs. I would eventually use these drawings during my manufacturing process.

MANUFACTURING

Facing off and cutting a 3 inch diameter aluminum rod, which was previously cut using a bandsaw.

Proceeded to cut the different diameters in both the cone and scoop.

I drilled and bored the pieces before tapering to make sure everything fitted correctly.

Afterwards, I made the curves on the cone and scoop using a radius cutter.

Lastly, on the vertical mill, I cut small grooves on the body of the cone, in order to give it texture and make it look more similar to a real cone.

FINAL