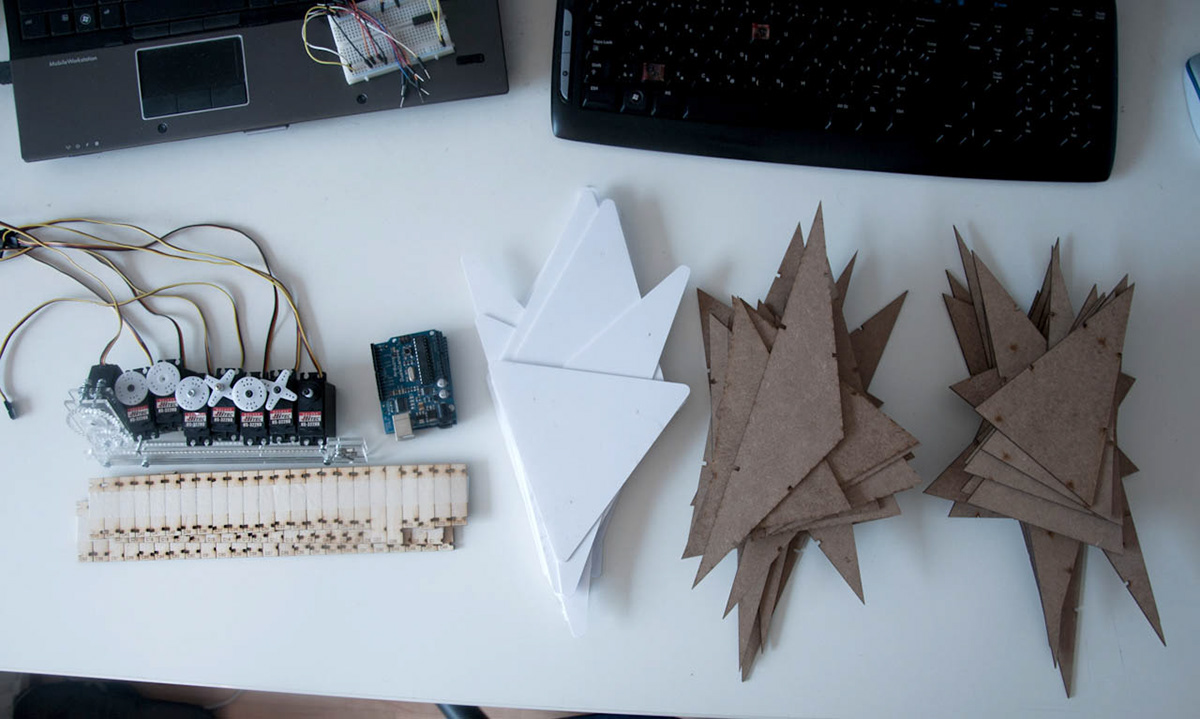

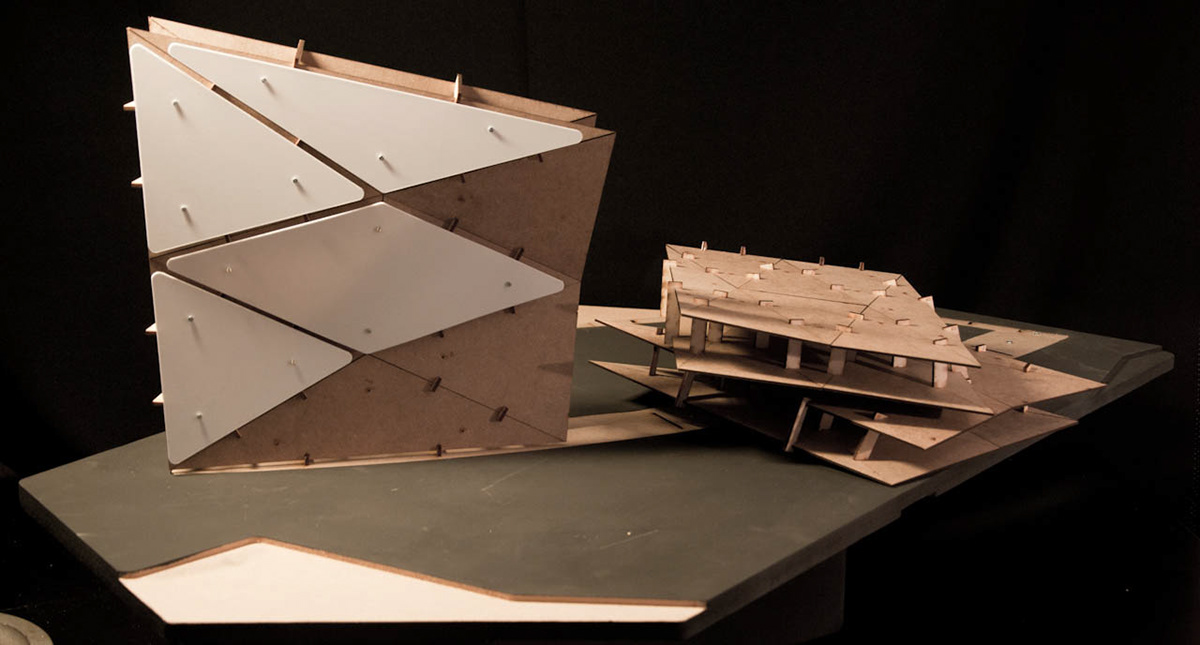

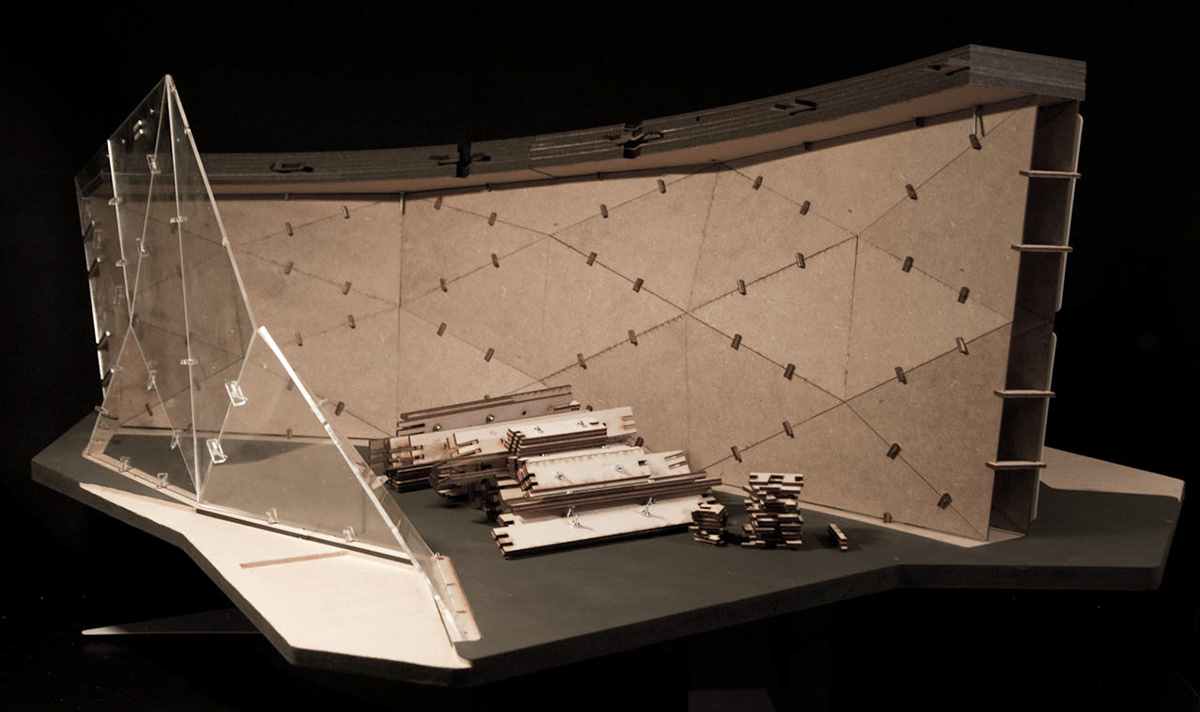

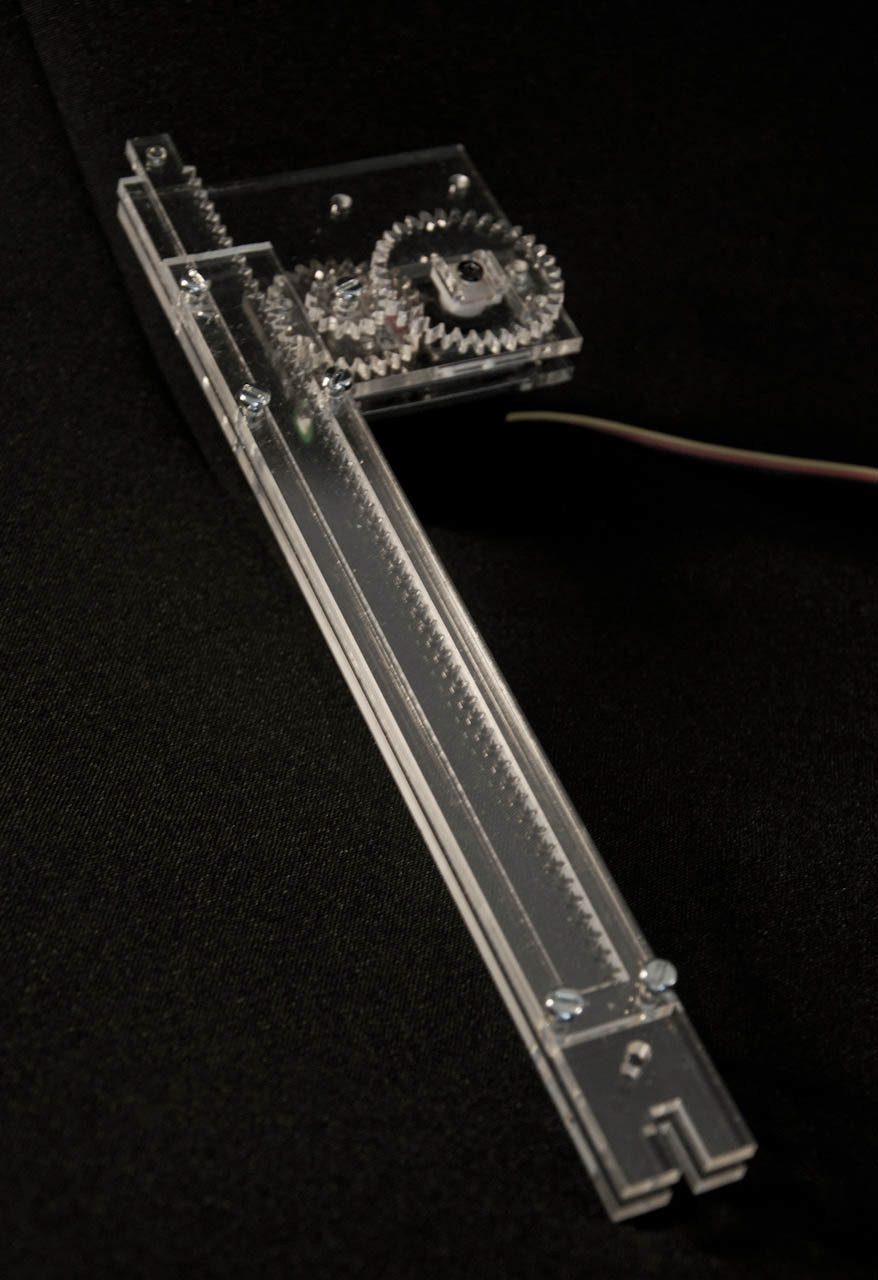

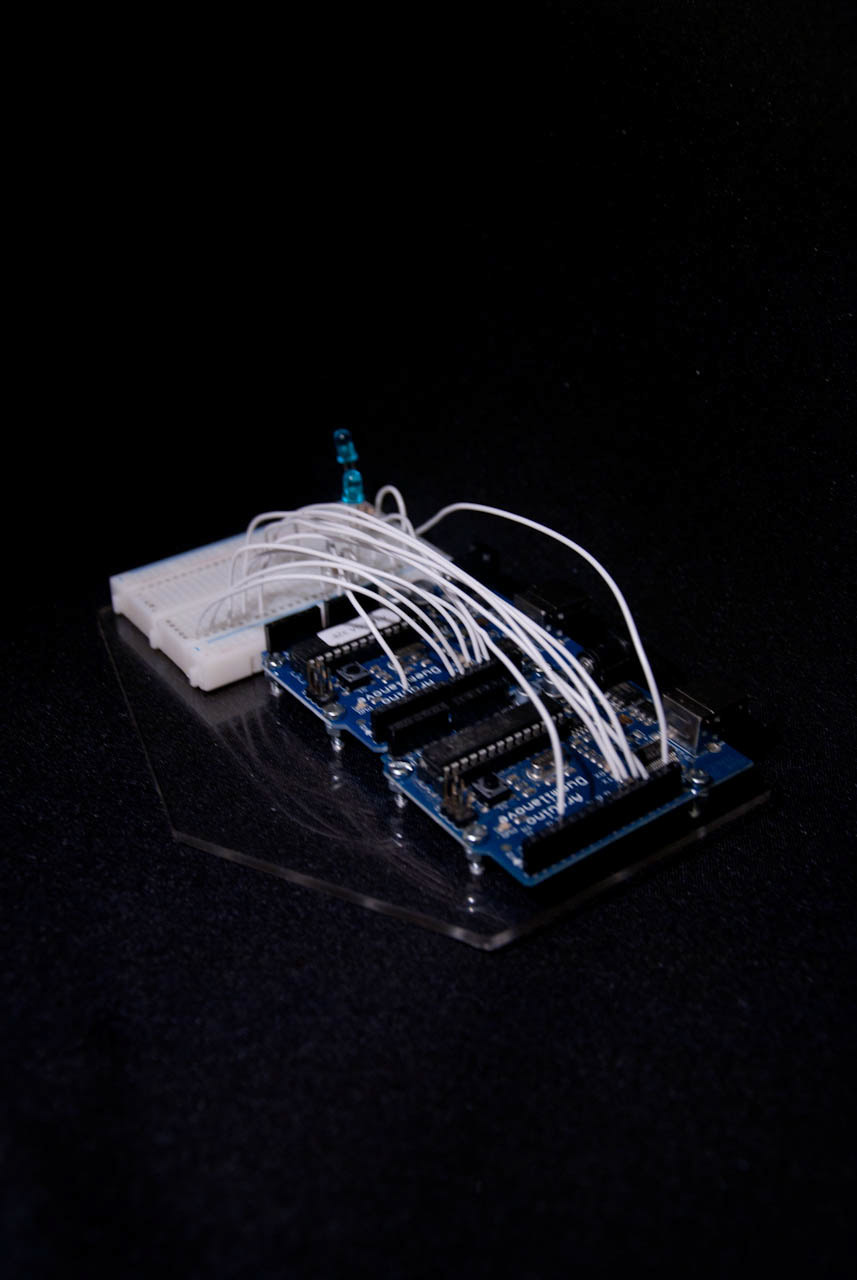

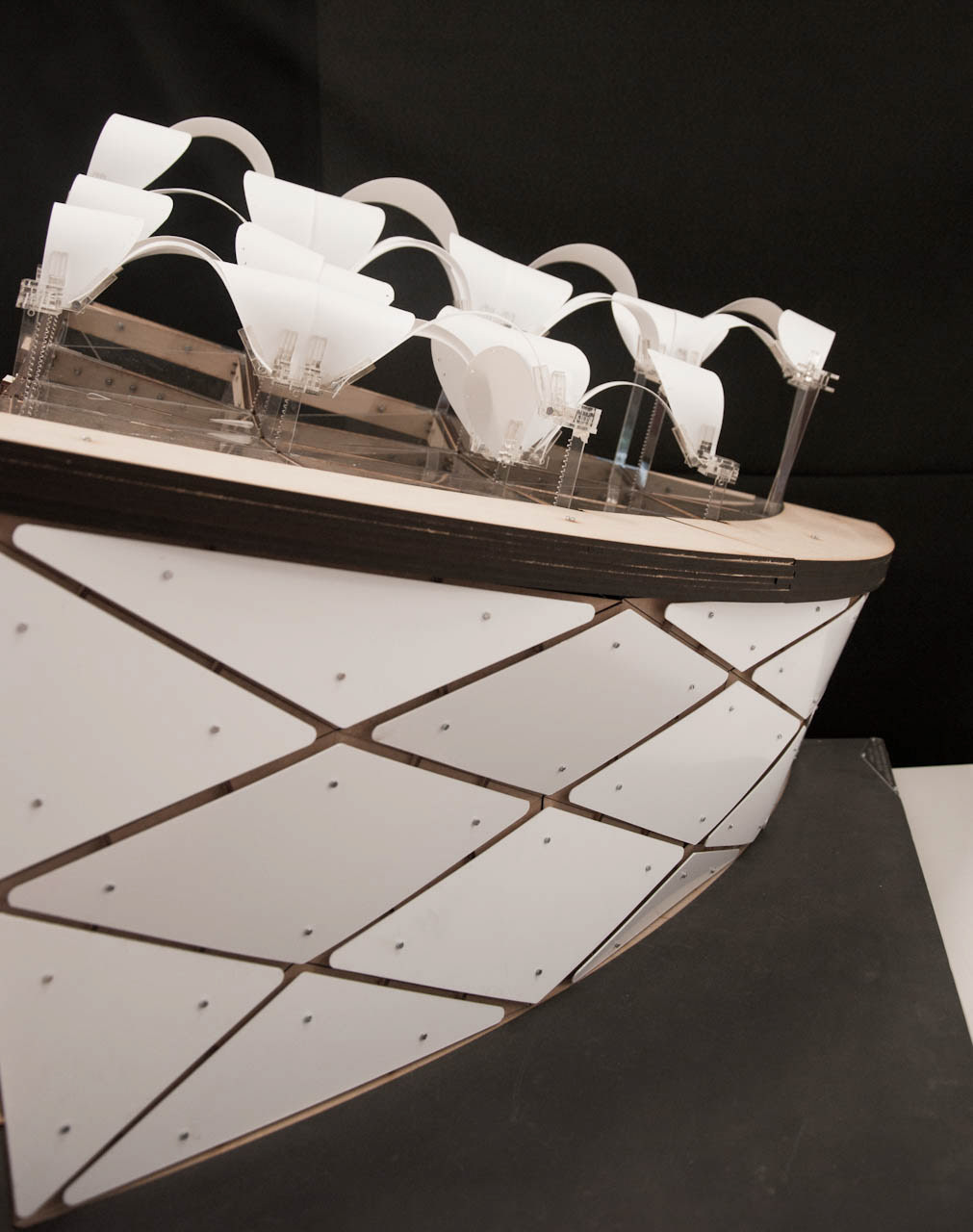

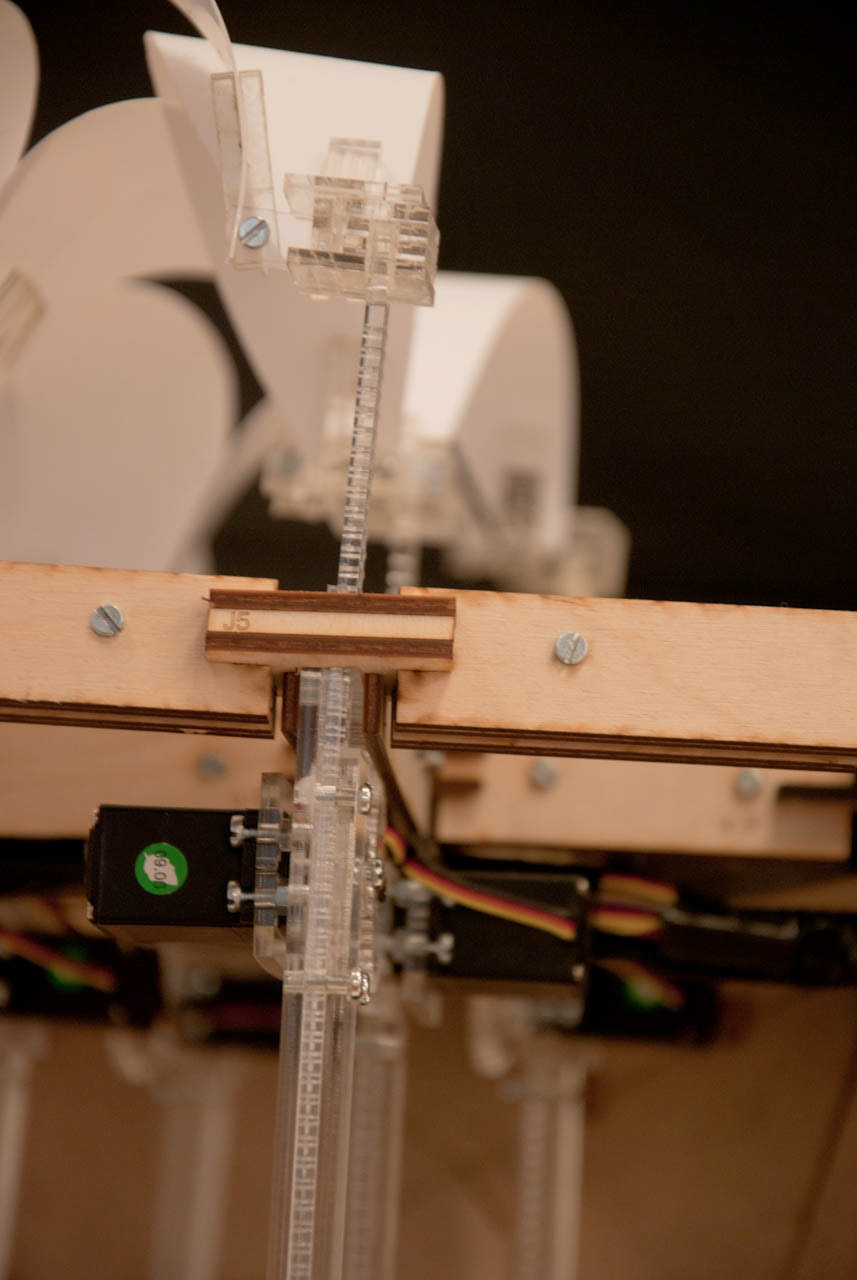

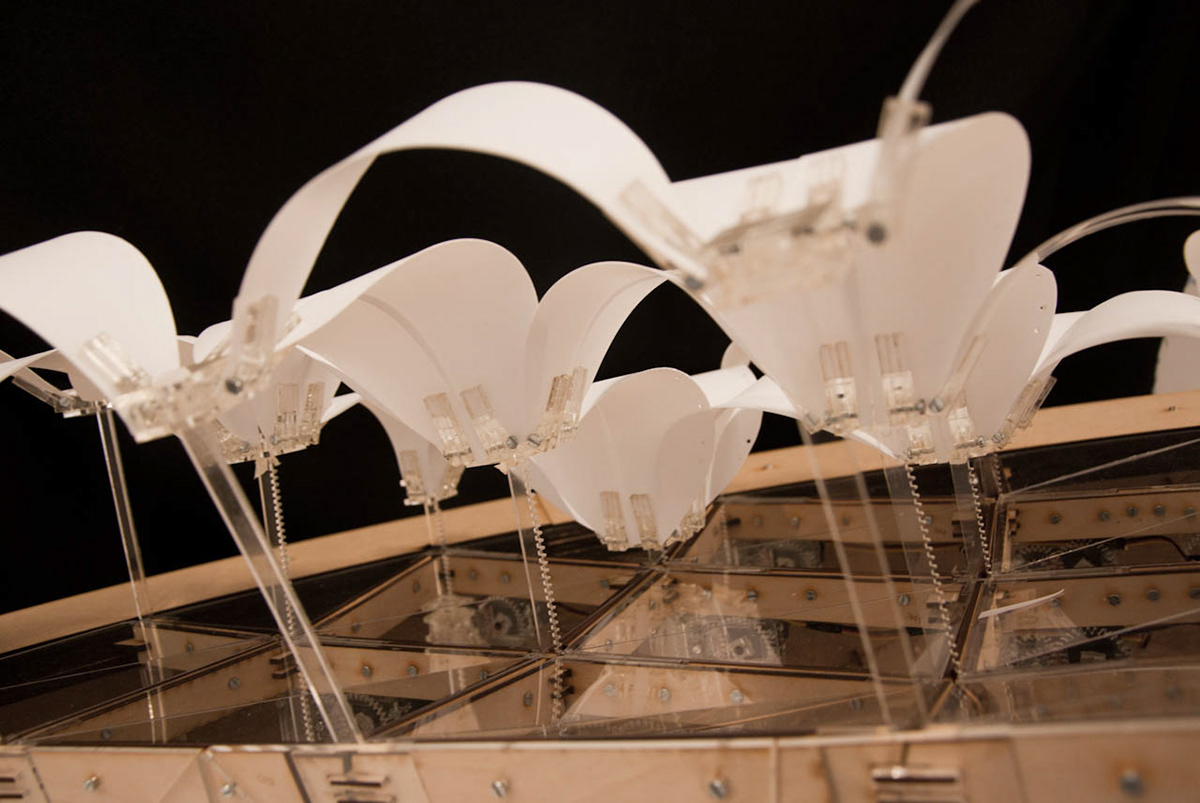

A reactive prototype was built to test asecondary responsive skin of theTransferium graduation project. Theprototype, in scale 1:10, consists of a walland roof section. The wall section teststhe assembly logic of a universalmass-customized component. Thedouble-skin roof tests behaviour of movingroof components and is constructed with11 customized pistons, mounted on 11servos. All servos are synchronized with 2Arduino boards connected to aGrasshopper interface.All components are unique and tagged foreasy assembly. CNC fabrication methods(laser cutting, 2 1/2D milling) allow allparts to be assembled glue-less, usingonly friction forces in joints.