Birth of Salt

PROJECT TYPE : Museum, Working space

DATE : 2016. 8 ~ 12

Personal project

LOCATION : Buan, Jeonbuk, South Korea

Project ‘Birth of Salt’ started from a thinking of ‘origins’ that form foundation of the human life. Among them, this project deals with salt which is essential but often depreciated because of its commonness and the process of sacred labor to produce it. Salt tastes food and replenishes the salt needed for the body. In the past, salt was deemed precious and used instead of money. As we entered the modern society, the factory was built and the salt was also mass-produced and its value was depreciated. As a result, the salt reached 100% complete salinity, and the traditional salterns, which were labor-intensive and uneconomical, were closed. However, some researches show that the higher purity salt is poison to humans, and the need for past production methods is emerging.

In spite of this situation, many people consume cheap and readily available factory salt, but there are still people who are sticking to the traditional way of production and trying to maintain healthy salt. These people constantly hold onto the strings of history at the 'Gomso salt pond' located in the south of South Korea. No artificial process can be found here. It does not dry out the salt, nor is there an electrolysis facility in the factory. Only the power of man sifting away impurities and drying salt with sunlight and sea breeze. Although the salt produced is expensive and there are not many people looking for it on the market, they feel proud and persistently stick to the tradition.

There are two major problems in this traditional way of producing nutritious salt. The first is to transfer the heavy salt, and the tidal workers are feeling a lot of fatigue. They have to shovel dozens of times for all the salt in one area size of only 9 square meter and transport 300kg of trailer to a distant salt store. Also, since the warehouse which dries a little is aged and the drying is not done properly, the workers have to turn over the salt piled up like a mountain from time to time. The second problem is that proper marketing is not done and there are no suitable consumers. As a result, tidal workers are forced to receive lower wages compared to the amount of labor they do. It is the goal of this project to provide solutions to these various problems. Through this project I wanted to record the sublime and authentic attitude of divine labor and the impressions from heart.

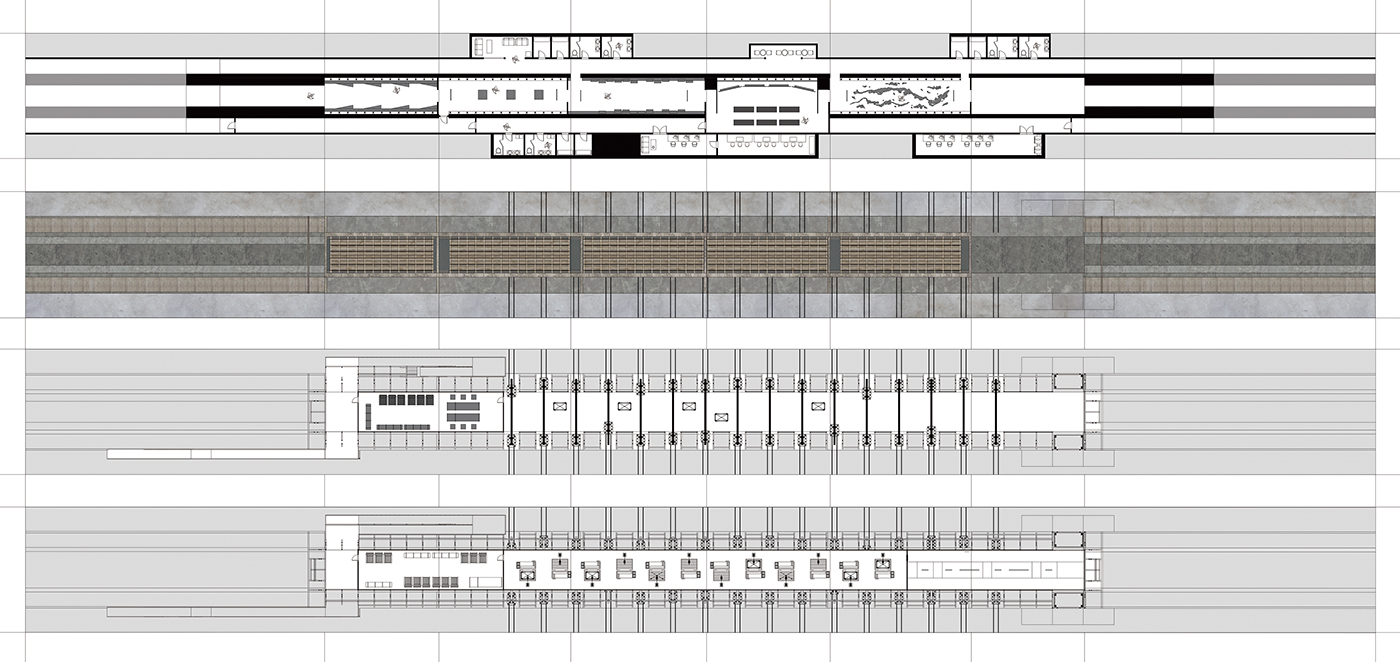

SITE PLAN of GOMSO salt pond

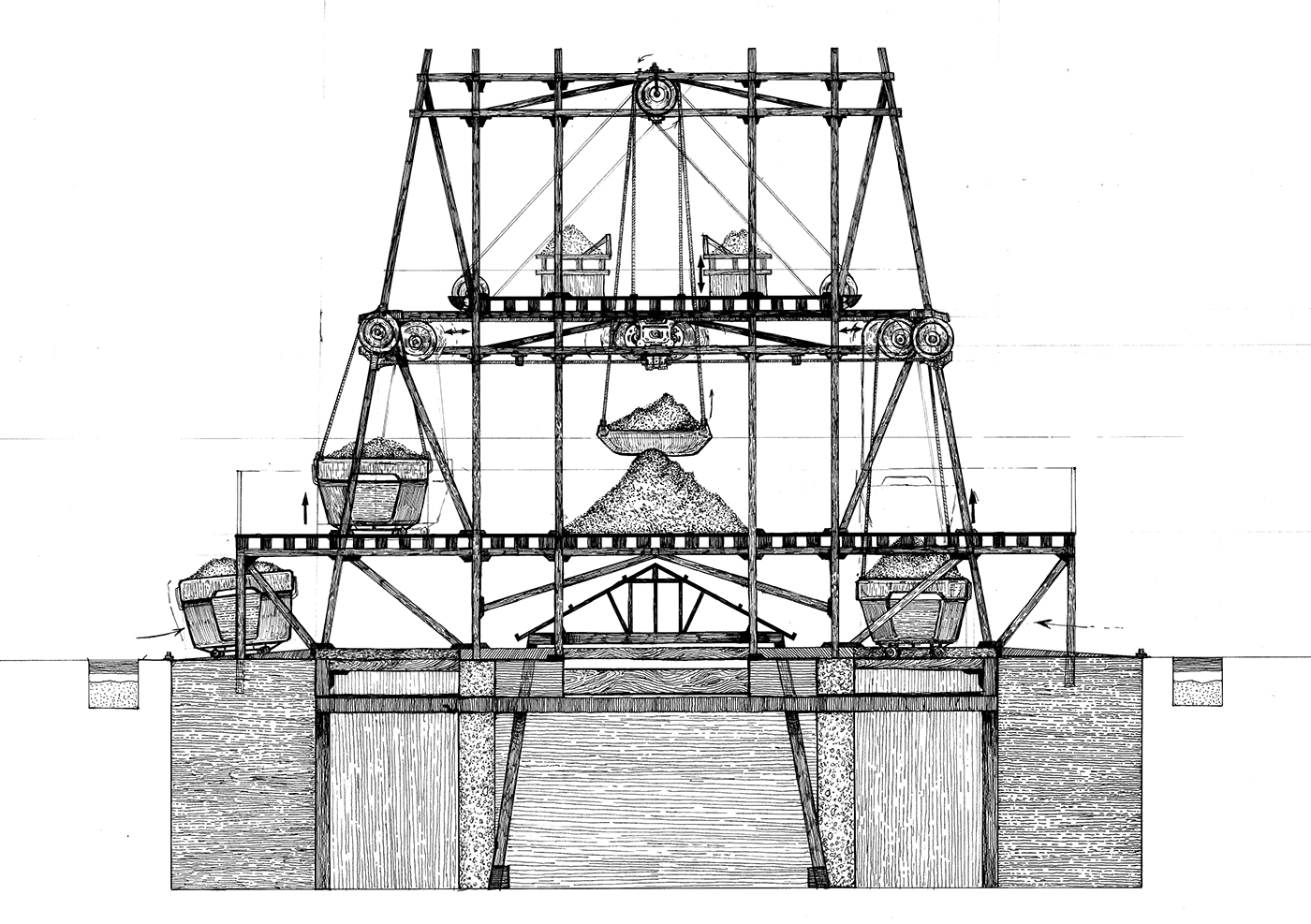

Salt warehouse section

The salt warehouse was created in order to store produced salt. The wooden parts between columns are finished with rough plate. The exterior is painted with col-tar for waterproofing. One of the unique feature of this building is angle of walls. These walls tilted slightly for withstanding rain, wind and salt pressures.

Detail of salt warehouse

Elevation

Circulation of water

The sea water, which is the material for producing the salt, is drawn through a nearby reservoir. The obtained seawater is precipitated, and the impurities are firstly filtered. After that, water is pumped through a water pipe installed on the rim of the saltern through a water pump. The pumped water flows into the primary evaporation site at the northern end of the saltern and water for salinity control can be introduced through the water pipe arranged between the grid section of the saltern.

Salinity difference

In the primary evaporation zone, seawater flows in. Salinity is expressed in degrees, which means the weight of water and salt. The frequency is changed by going through evaporation paper. It varies from 6 to 8 degrees on the primary evaporation site. It then changes to 14-18 degrees in the second evaporation site and 25 degrees in the final crystallizing site to properly harvest the salt. At 25 degrees or more, the bitter taste of the salt becomes stronger, so more than 25 degrees of water will go back to the sea through the gate.

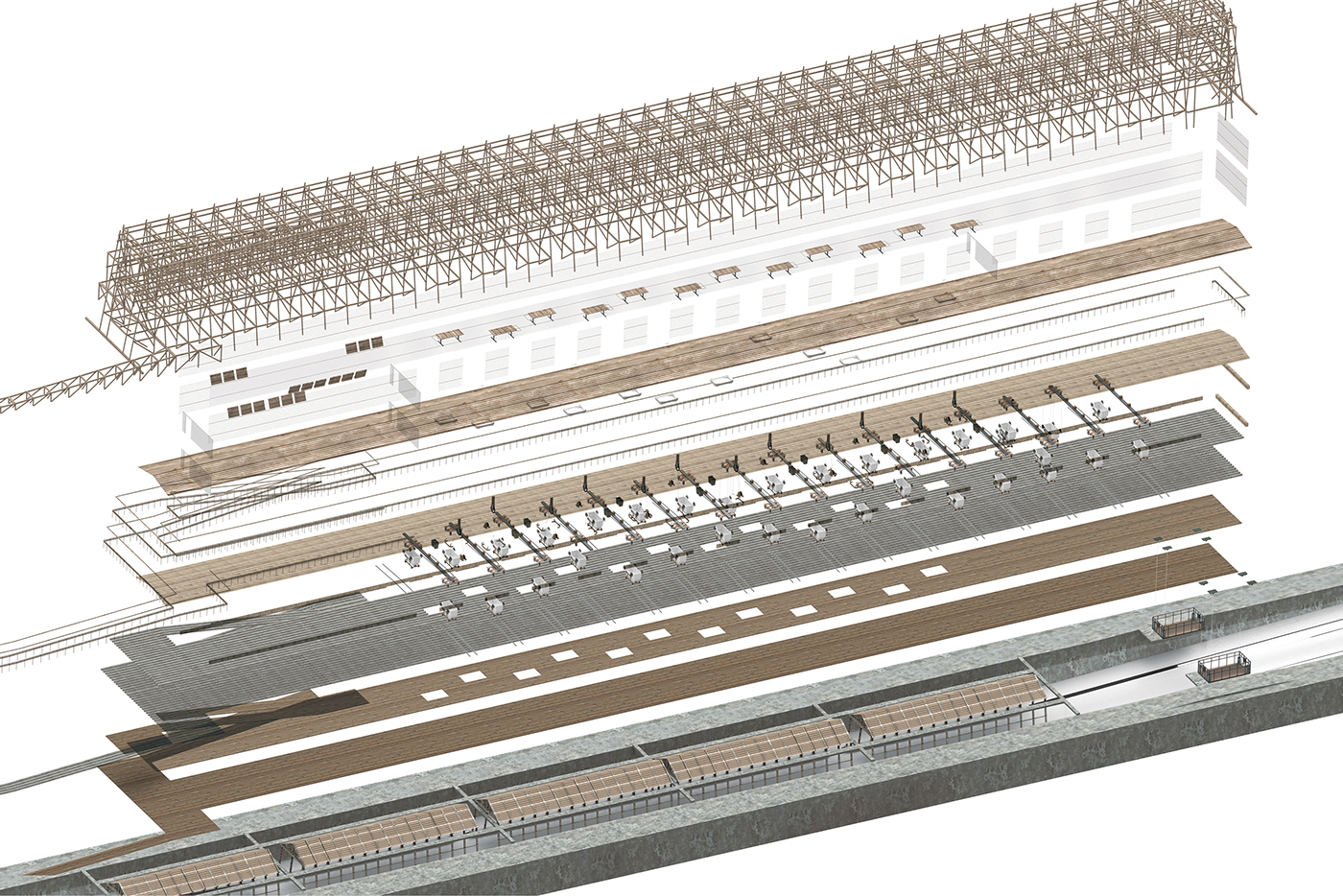

Structure

Floor plan

Drawing

Perspective view

2F Salt warehouse

The existing salt warehouses were more than 50 years old with a closed off structure. As a result, it was easy for the salt to be contaminated and difficult to let out the moisture. To solve this issue, the warehouse needed an open space with air circulation. Furthermore, it took workers a long time to transport the salt from the saltern due to distance resulting in fatique. Using the second floor improved worker productivity by using a pulley resulting in less distance traveled. The building is long and regardless of where you bring the salt from, due to the large surface area for the salt to airdry, the drying process has been accelerated.

2,3F Lounge

The Saltern workers did not have any resting area despite the physical intensity of the job. They had previously kept chairs and lighting in the warehouse for temporary rest and it was extremely cramped. The lounge on the 2nd and 3rd floor solves this problem. The lounge is near the workspace making it easier to prepare woirk and find rest when needed. in addition being near the sea, saltern have strong seabreeze so the lounge was surrounded in glass for proper shelter. The glass shelter allows workers to check the progress of the work while resting.

3F Packaging place

Gomso salterns are processd at factories far away from the saltern. Due the distance it’s important to dry the salt before moving to the packaging plant. The 3rd floor packaging station was designed to reduce this process. The dried salt from 2nd floor is raised through a pulley using baskets and packaged enhanced process saves transportation costs and leads to direct sale of the product. The packaging station also allows extra savings form shipping directly to other places instead.

3F Direct outlet

One of the most chronic problems the saltern faced was its lack of marketing. By setting up an exhibit detailling the history, production process and value of the saltern as well as a direct outlet, visitors are able to witness the entire process and gain trust leading up to the purchase. Through a glass partition, visitors are able to see the actual salt packaging process.

Exhibition space (History of Gomso salt pond)

Exhibition about materials and environment

Exhibition for salt harvesting process, tools and value of labour

Story of salt whice is come from the earth

Installation art zone with salt as an artwork and visitors.

Mock-up

Mock-up

Contact

Yoo, Jaehyeong

Seoul National University

BA, College of design, Industrial design

------

soulyooza@gmail.com

instagram.com/yooza_yooza

+82 10-5771-5623