Five years ago, I began exploring direct injection of rubber onto leather for outdoor footwear. A large amount of time, engineering and money went into developing the molds to create a bond with the two materials. When I finally received the sample, I thought the process could be greatly simplified by 3D printing directly onto the material. Unfortunately though, at the time, only hard materials such as nylon could be 3D printed. With the recent rise of FDM printers and the growth of new, more flexible filaments, I decided revisit my past theory of 3D printing directly onto materials.

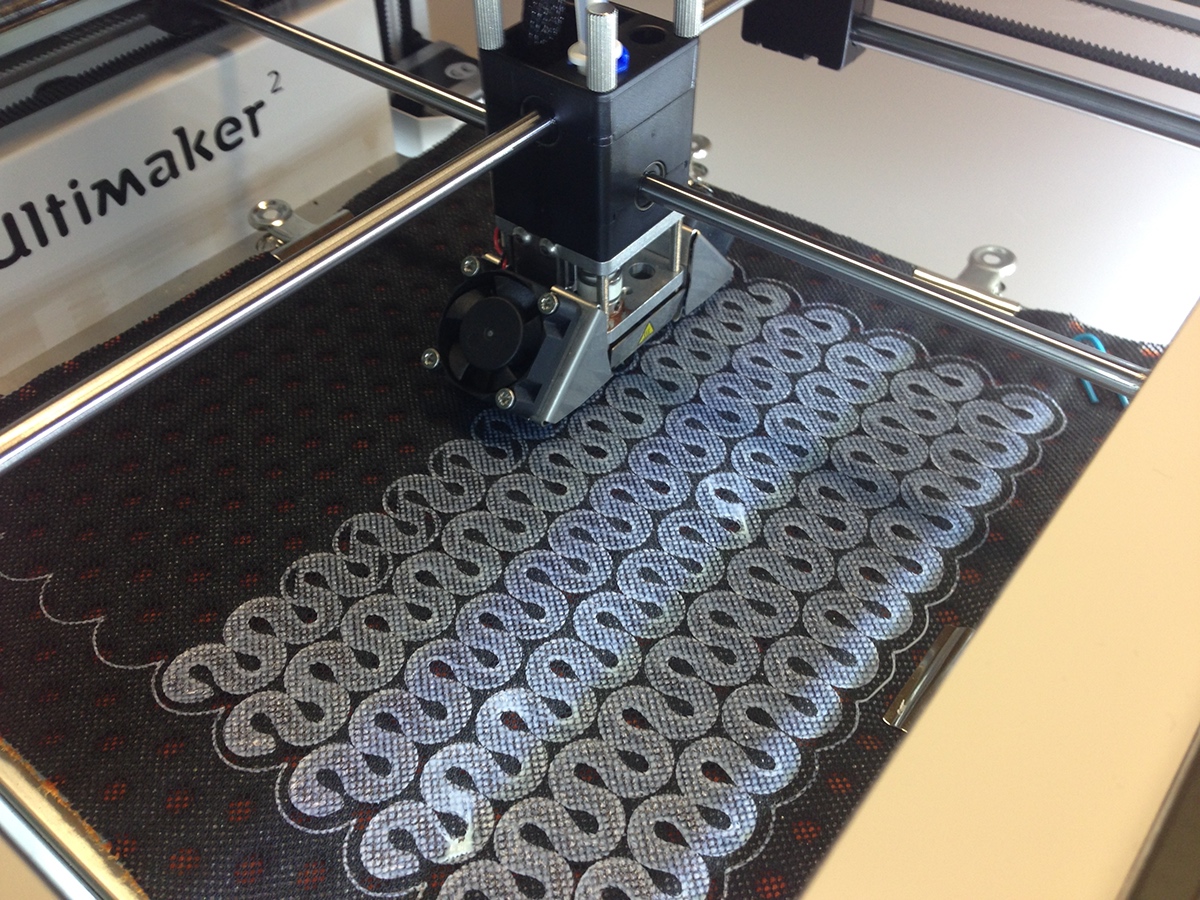

I began by searching for any information I could find about others in the industry exploring this type of 3D printing. This led me to begin my own experiments of trying to bond new rubber and flexible PLA filament onto mesh, rubber, canvas, felt and leather. Since the filament was so new, there weren’t any guidelines to follow for the heat and print settings. On top of that, I decided to add another variable to the equation by using several different textiles. Through many rounds of trial and error, I managed to find the right combination of printer settings, filament and material to successfully print directly onto the material. I was able to prove that you can print actually print an upper’s pattern pieces. You can now literally break the mold and build various heights on an uppers as well as structures that you cannot produce with a mold. I am still continuing to explore 3D printed uppers with other new filaments and can’t wait to see what other discoveries I can find.