Peter Kovacsy is a highly skilled master wood craftsman and designer-maker. He specialises in utilising native Australian timbers. The project below documents his construction of a hand made stitch-and-glue wooden boat.

The craft is a Woods Design "BEE" that is 4.86 meters long and is rated as sea worthy rowing boat. Peter's version has been redesigned for a high performance sprit rig, sail, spars, rudder and centre board.

Hand crafted Stitch-and-glue boat by Australian wooden boat maker Peter Kovacsy

Hand crafted Stitch-and-glue boat by Australian wooden boat maker Peter Kovacsy . The skiff fully rigged and ready to sail - at Walpole Inlet on launch day.

Hand crafted Stitch-and-glue boat by Australian wooden boat maker Peter Kovacsy - The skiff sitting in the water at Walpole on launch day.

Hand crafted Stitch-and-glue boat by Australian wooden boat maker Peter Kovacsy

Hand crafted Stitch-and-glue boat by Australian wooden boat maker Peter Kovacsy

Stitch-and-glue boat building by Australian wooden boat maker Peter Kovacsy - Huon pine stem post cap being caved to shape.

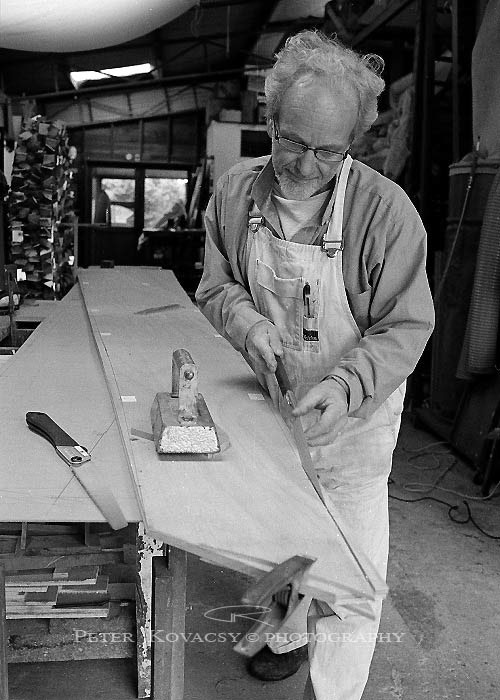

Shaping the stem cover timber to the hull lines.

Gluing the outer gunnels to the topside.

Gluing the inner gunnels to the topside.

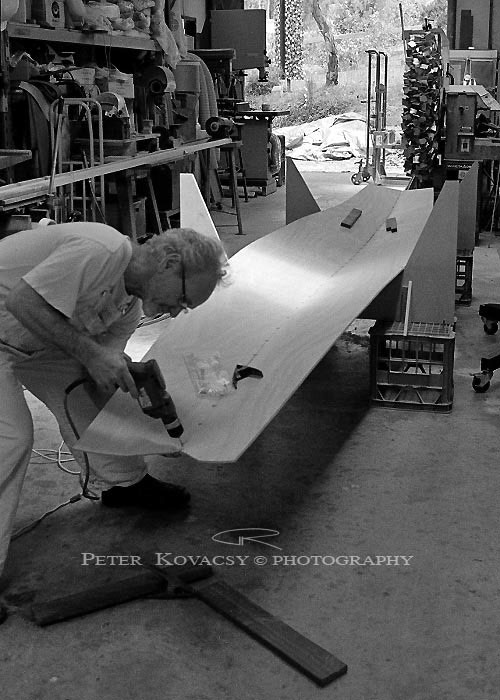

Stitch-and-glue boat building - Peter Kovacsy drilling holes along the chines for copper wire ties.

Stitch-and-glue boat building - Fitting the reverse transon - drilling holes for the copper titich wire.

Stitch-and-glue boat building by Australian wooden boat maker Peter Kovacsy

Laying the topside ply onto the lower hull ply - then touturing fto shape from the stem to the aft. Soak the front lower section ply overnight !

Stitch copper wire along the centre chine.

Stitch and glue is an easy ply wood hull system construction system. The tricky thing is getting ply to cope with the "torturing" Tick: soak ply overnight - around areas that are going to be under high strained.

Stitch-and-glue boat building by Australian wooden boat maker Peter Kovacsy

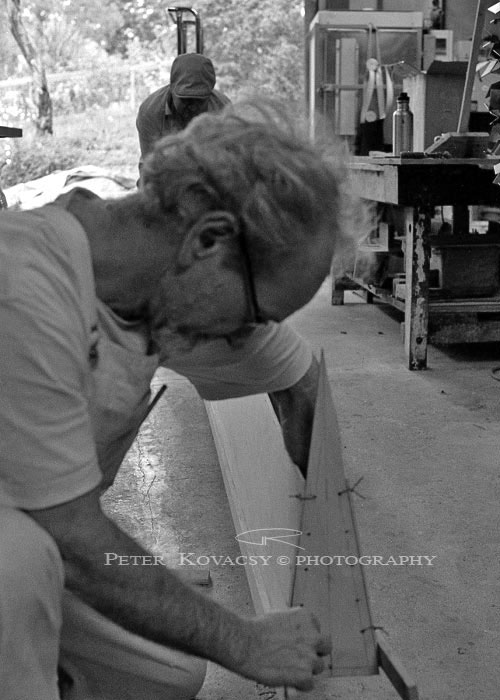

Pre-drill stem ply cap to topside ply - ready for copper stitch wire.

The stem ply is a tricky component to fit - loose tie in place to the topside ply with copper wire.

Pre-drill holes and loose tie copper sticth wires along main chine.

Anealed - heavy duty copper tie wires are fitted - used to pull ply together along the chines.

Bote-Cote epoxy glue being applied to bond gunnel stringers to the topdise ply - outer side.

Peter used a Japanies saw to cut topside and lower side ply to final shape - after ply is scarf jointed to lenght.

Pre cut topdise and lower hull ply - scarf joints are stapled together - while Bote-Cote epoxy bond sets.

Bote-Cote epoxy applied to scarf joints.

Making scarf joints - connects 2.4 meter lengths of ply together to form 4.8 meter topside and lower hull.

Fine scarf joints being shaped - all ply and gunnel componets for this carft required 4.8 meter lenghts. This type of bonded joint is stronger and lighter.

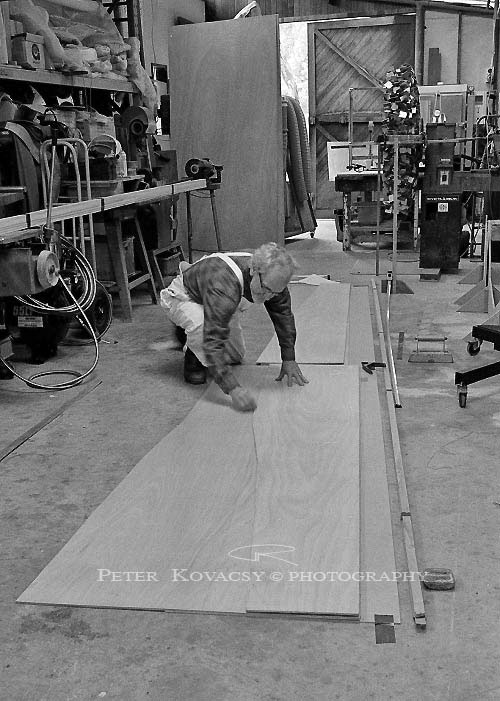

Lofting ply to shape - pre cut oversize - for bonding to overall lenght.

Peter cutting all the 2.4m ply to shape - cut slightly oversize at this stage - ready for bodning to overall 4.8m lenght.

Laying out the shape for the ply - using the lofting plan.

Scarf jointed gunnel stock - bonding.

Bonded scarf joints held in place with weights - hold while Bote-Cote epoxy sets.

Bote-Cote epoxy resin being apllied to the gunnel stock scarf joints - ready for bonding.

Peter made a jig for the bandsaw - to produce fine scarf joints for the gunnel stock.