Micro - Mobile EV +

A Semi - Micro Mobile EV that incorporates convenience from compact MMVs & efficient performance from two-wheeled vehicles.

Product category: Transportation Design - Electric Vehicles

Industrial Design | 04 Months | September 2022

Transportation Design

Type: Pre Thesis - Semester 07

Time: 04 Months

Team: Individual Project

Brief

Ward 110, a lively commercial marketplace in the heart of Bengaluru houses a variety of business such as manufacturers, import/exporters, repair centres and spare part suppliers. Inefficiency in commute of solo travellers working there has worsened traffic conditions. Cities are getting heavily populated unable to house the sheer mass of people. Mobility for solo travellers has hardly seen advancement, with saturated public transports, last mile connectivity is scarce, less available and not cost effective. Due to this most market places in ward 110 lack accessibility affecting employability and eventually affecting businesses.

The brief was to bring an intervention into the ward 110 business community helping users to navigate through this vast stretch of market intern boosting the wards efficiency. It should be able to benefit business establishments small & big and should also create an impact outside the designated marketplace.

Contents

Introduction & Research | Sustainable Development Goals [SDG] | Case-studies | Business Model | Conceptualisation & Ideation | Prototyping | Final Product | Awards/Honours

Product

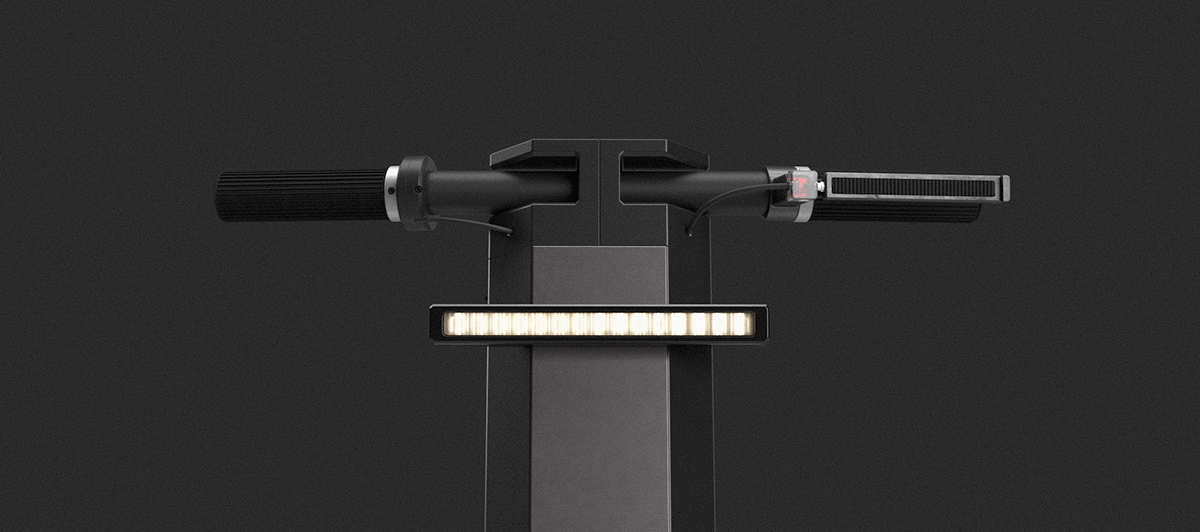

This semi-micro mobile EV sits in between two drastic categories, compact MMVs that maximise convenience over performance and generic two-wheeled vehicles that maximise efficiency and performance over compactability. It harnesses a similar MMV body framework enabling users to cut through short-distance traffic by utilising both roads and pavements. Its narrow and sleek design helps manoeuvre it through significantly thinner gaps.

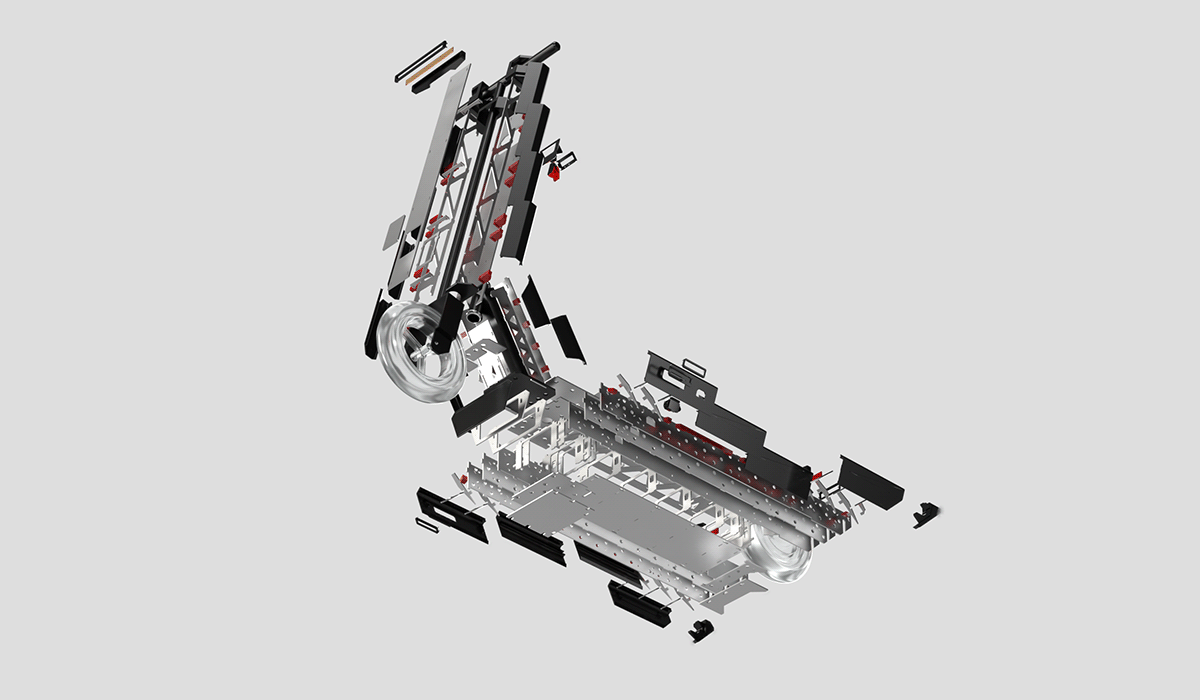

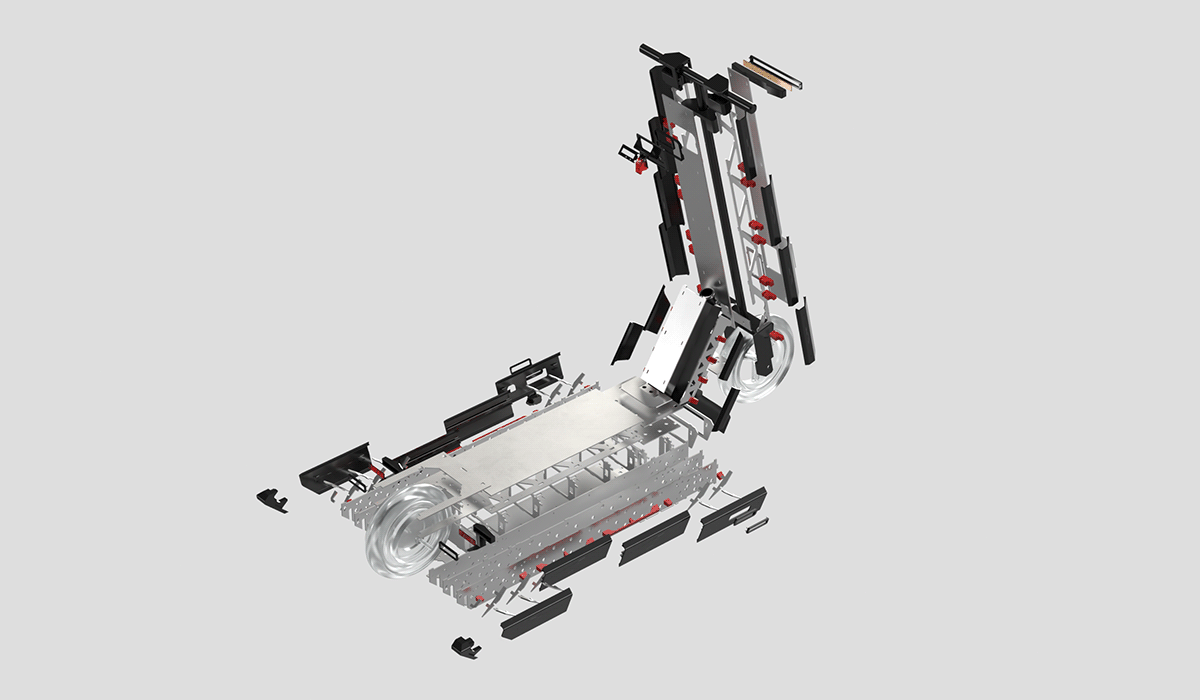

The EV incorporates cutting-edge performance with a high-functioning lithium-ion battery with an average range of 25 kilometres, that sits under the footrest and a secondary battery for regenerative breaking placed in the frontal panel. The secondary battery harnesses kinetic energy lost during braking before converting and storing it as electrical power, this in turn charges the primary battery increasing its output significantly. The added front panel not only acts as a shield against minor collisions but also balances out the rear motor weight bringing the centre of gravity in line with that of the user maximising driving control. The vehicle is driven by a high-torque 24V - 350W rear electric hub motor. A fully aluminium 6061-T6 aerospace alloy makes up the significantly lightweight chassis of the vehicle, providing strength, anti-corrosion and effective heat dissipation for the battery. Limited access to the battery enclosure ensures safety for the user and pedestrians in the event of an accident, containing harmful fumes and avoiding combustion. Lightweight ABS body panels protect the mainframe from damage and ensure convenient/cost-effective replaceability & maintenance. The frontal panel, handlebar module and wheel covers increase the product's aerodynamics cutting and redirecting air around and over the user. The design supports a seat attachment that can be added for longer travel distances. A manually adjustable sleek high beam headlight lights up the road ahead. Indicator lights on the rear and either side ensure the user's and vehicle's visibility in low-light conditions. A retro aeroplane switch powers the vehicle after the key switch has unlocked the vehicle accompanied by a small display indicating the speed, voltage and battery capacity along with an overheating indicator. 10 - inch pneumatic wheels reduce weight and absorb shocks eliminating the need for external suspension. An innovative mudguard design covers what's necessary, keeping the attachment light, aesthetic and functional. A lockable carabiner helps users securely hang belongings such as small bags or even a helmet.

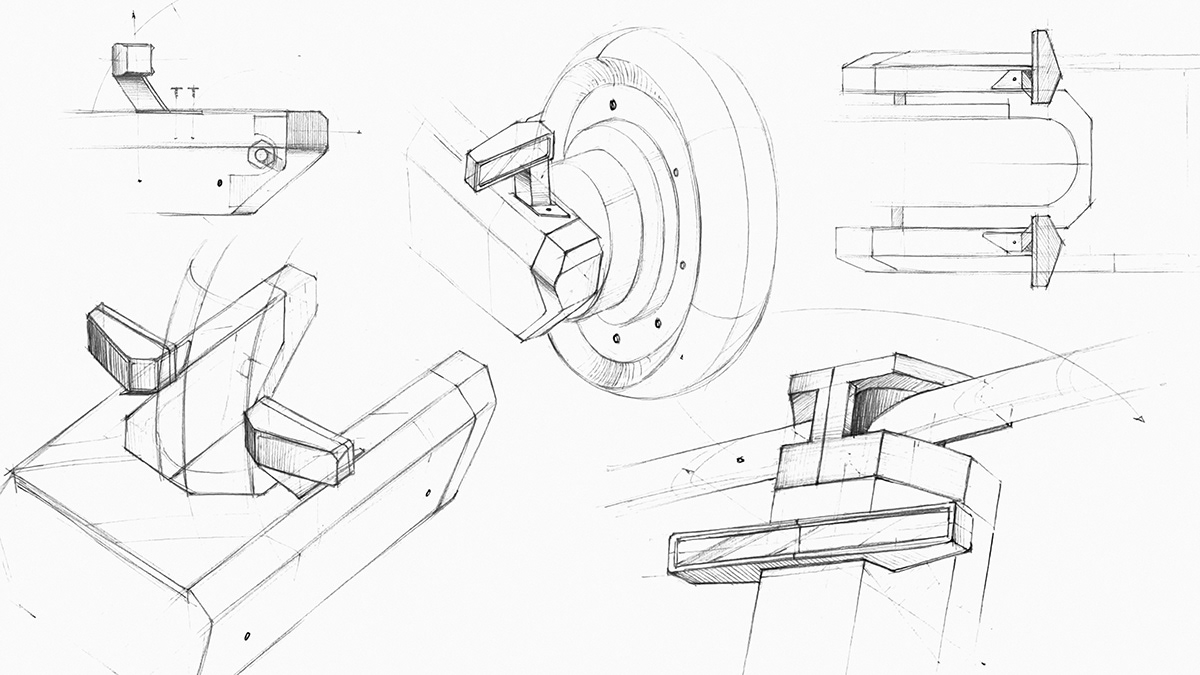

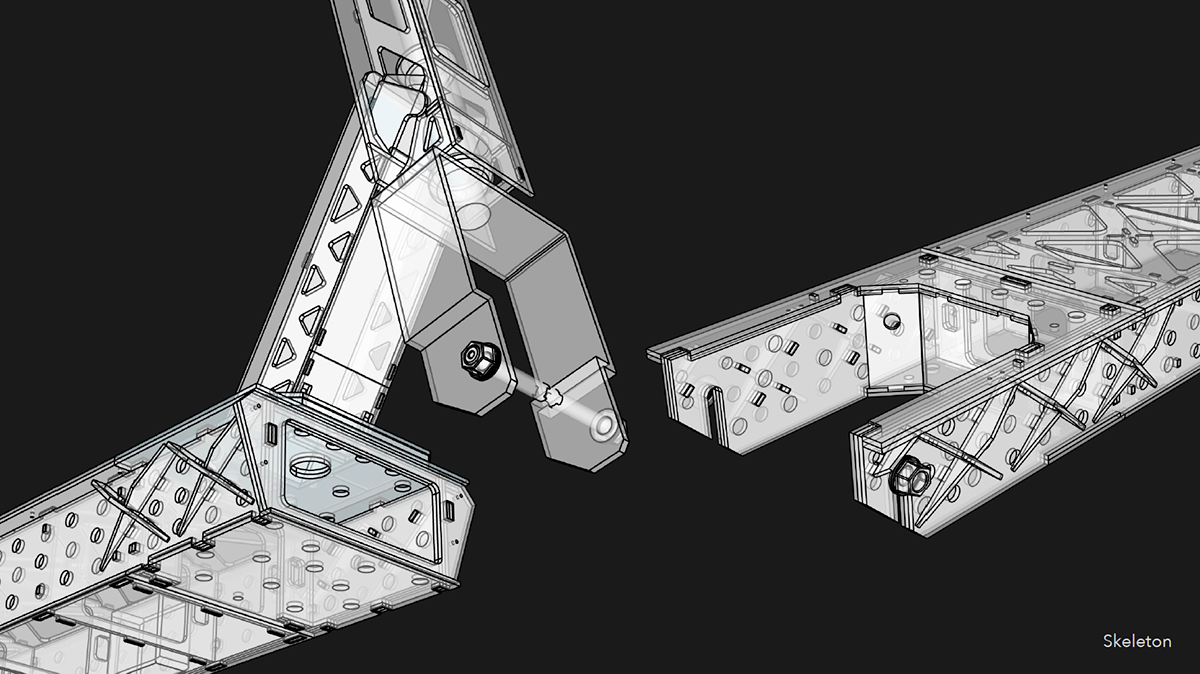

Mechanics

The EV chassis follows a unibody construction over a body-on-frame assembly. This is because unibody frames incorporate the strength aspect into the chassis using the panels themselves, which makes the body sleeker, more accommodating towards components and lighter in weight. Sheets of various shapes pre-cut, slot and interlock together for efficient assembly and increased strength. This method is implemented by the majority of middle + high segment automobile manufacturers both for EV and non-EV. What separates these two methods when it comes to mass manufacturing is the difference in cost and time. Body on frame is a simpler and cheaper method of making chassis and is usually used for low-segmented vehicles or even heavy-weight vehicles such as buses and trucks. It usually consists of a ladder frame that is the backbone of the vehicle, it supports heavy components such as the engine, transmission, wheels or battery. The frame that encapsulates the driver is then attached to the frame externally. Since this micro mobile EV due to its use of relatively expensive components and technologies falls under the premium vehicle segment, the unibody method is implemented as it caters to its performance needs more effectively.

M i c r o - M o b i l e EV

Transportation Design

Low - Fidelity Prototyping Stage 02

Foam board + Essential components

High - Fidelity Prototyping Stage 03

Final Product

end