aerolock

I chose to focus on bicycle security for my senior capstone project. Although there are numerous lock designs out on the market, none successfully solve all the separate issues involved. Conventional bike locks are designed with little regard for portability and can be quite a burden while riding. They should be convenient to carry and use while also being secure enough to stand up against the relentless tactics of modern bike thieves. The aerolock is designed for not only the bike rack, but the ride as well.

I began my research by talking to bike commuters, couriers, and shop employees all about bike security. I then wrote up a survey, which I had people fill out at local bike shops and trails. Based on this feedback, I began further market research and product testing, looking for actionable insights and design opportunities.

Nearly 9 out of 10 people need a bag with them to carry their lock. This turns the lock into a burden and often discourages people from using their bike. The ‘tried and true’ u-lock dominates the market, as it’s secure and easy to use.

Frame-mounting brackets are available with some locks, but will not fit all frames due to the many different frame styles and sizes. Even if the frame is compatible, the lock may not fit with all the other accessories typically carried on bikes. The front of the bike is an easily-accessible area that isn’t excessively occupied.

Nearly 9 out of 10 people need a bag with them to carry their lock. This turns the lock into a burden and often discourages people from using their bike. The ‘tried and true’ u-lock dominates the market, as it’s secure and easy to use.

Frame-mounting brackets are available with some locks, but will not fit all frames due to the many different frame styles and sizes. Even if the frame is compatible, the lock may not fit with all the other accessories typically carried on bikes. The front of the bike is an easily-accessible area that isn’t excessively occupied.

Conventional locks are the very definition of deadweight. While riding, they are an awkward, useless, heavy burden. Most people must resort to carrying their locks in a bag or on their body somewhere, which is dangerous and uncomfortable.

Each type of lock has its pros and cons. Cable locks are easy to carry and use, but can be cut through like a stick of butter. Chain locks are very strong, but extremely heavy and a pain to carry. The U-lock is a good all-around lock. It’s secure and fairly compact, however, it can be pried open with a car-jack.

Modern bike thieves are using more than bolt-cutters these days. Angle-grinders and sawzalls will get through pretty much any lock, but are not practical for covert theivery. Liquid nitrogen can be used to freeze and shatter locks, but this is very dangerous and the materials are not easy or cheap to acquire. Car-jacks and other pry-tools have become many thieves’ weapons of choice, especially against u-locks - bending and breaking them open quickly and discreetly.

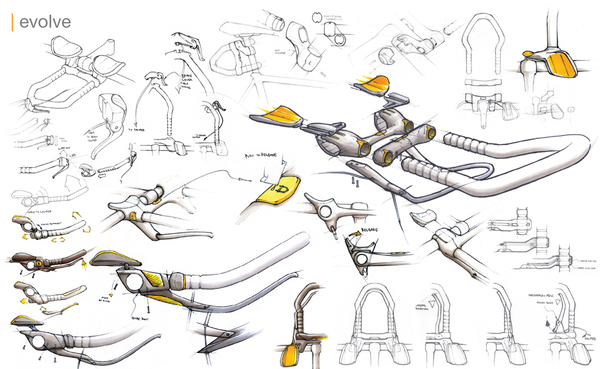

With the problems established, I hit the drawing board and began to explore different locking and attachment options. I focused on security improvements to prevent car-jack theft, while also thinking about convenient transport and usability. Initial concepts included ideas such as bar-ends that detach and become the bike lock.

I chose to pursue a synthesis of a u-lock and aerobars. This concept would improve usability while on and off the bike, thereby enhancing the entire journey. The mounting location would not interfere with common accessories like water bottles, racks, or bags.

During the ride, it can be mounted to the front handlebar and used as a set of aerobars, providing a more ergonomic, comfortable and efficient ride. When not riding, the lock may be detached from mount and used to secure the bike.

During the ride, it can be mounted to the front handlebar and used as a set of aerobars, providing a more ergonomic, comfortable and efficient ride. When not riding, the lock may be detached from mount and used to secure the bike.

After further research into aerobars, I found that the most prevalent concern for users was the lack of a safe braking method. I began exploring possible brake-integration, as well as armrest ergonomics and usability. I also focused on a universal mounting-interface that would be compatible with the handlebars and the frame.

This exploded line drawing shows the four main groups which make up the aerolock system. The lock and mount components are the core of the system. The arm rests can be attached to the back of the mount, and allow aerobar usability. The brake lever, which can be used in addition to original brake levers, is also optional, and attaches to the bottom of the mount.

The entire final model was made by hand, without the use of CNC or 3D printers. The lock, mount, brake, and arm rest lever were carved from high density ren shape foam, and then painted. The arm rest plates were laser cut acrylic that was then thermal formed and painted. The arm rest foam is a closed-cell foam that was cut, molded, lightly sanded, and painted. The stem, drop bars, and allen screws were taken off my old bike, cut to size, and painted.

After a week of hard work, the final model is complete. Working hinges and detachable parts with real hardware effectively explain the primary functions of the final design.

On the bike, aerolock provides an alternate riding position for a more aerodynamic, efficient posture, relieving stress from the wrists and butt, making it ideal for longer rides. When not in the ‘aero’ position, the armrests swivel up and out of the way, as shown here.

Off the bike, aerolock is designed to prevent all methods of theft, especially pry theft. An adjustable enclosement area allows the lock to cinch down tightly and block tool entry. The lock’s angular form also eliminates parallel points inside the enclosure, preventing pry-tools such as car jacks from gaining leverage.

As my senior capstone project, aerolock won top honors and main exhibit of the 2009 University of Washington Design Show. It was also featured on Core 77 and presented at the 2009 IDSA Western District Conference.