Brief:

Respiratory humidifiers and connective tubing

Fisher & Paykel Healthcare were looking for up and coming designers to help inspire their team in the redesign of their MR850 humidification device.

The project was specifically geared at creating a future focussed solution with the aim of improving the usability experience for the end user (Nurses). In a hospital context, respiratory humidifiers are used as a means to humidify and condition cold and dry gasses that get delivered to patients who require ventilator breathing assistance. After conducting extensive research in the form of extreme user interviews in two of Auckland City’s leading hospitals, it was found that: Nurses were known to get confused when setting up the complex system of tubing that lead to the main heater base, which consists of 6 possible therapy setup combinations with an average of 15 steps. On many occasions, this would lead to the incorrect setup of the system, leading to potentially dangerous medical errors. In some cases, nurses would attempt to force/add components to fit together where they weren’t intended to, whilst believing that they’ve setup the system correctly. The same tubing was also incompatible in fitting a range of associated hospital equipment, such as cheaper, foreign oxygen masks and ventilators. Other challenges included a short tubing life span of 7 days per patient, an energy hungry heater base, substantial condensation build up in the tubing and a poorly designed digital user interface on the heater base.

Oxygen Masks

Patients also experienced great” discomfort” when using contemporary respiratory masks, due to its size, heavy weight and exerted pressure on the face, which would in many cases result in facial sores/skin decay. These masks where also known to adversely affect the psychological wellbeing of patients, as it’s hot, overbearing internal environment and facial obstruction contributed to a sense of claustrophobia. Hospitals where also known to use a variety of masks per patient, due to budget restraints and functional restrictions, which meant that the life span for individual masks where short and restrictive. In addition to this was the masks ” invasive aesthetic” which gave onlookers/loved ones a sense of great discomfort and concern when visiting patients.

Education

Lastly, because the training of hospital staff is costly as well as the nature in which hospitals run, meant that Fisher and Paykel Salesman couldn't access the majority of those using their products for educational tutorials. This lead to having to equip their products with vector image instructional swing tags as the current system has over 15 required setup steps across 6 different therapy setup combinations, making setting up the system a total nightmare. With an overload of info, and info that’s unnecessary for what they require, images/instructions where too hard for nurses to interpret, which lead them to create their own setup manuals in ways that where easier for them to understand. Lastly, nurses would also often break open other identical humidification/pipping packages to seek parts that they’d accidentally damaged or lost when trying to setup previous systems, which would result in the contamination of the entire packages contents due to the exposure to air born contaminants.

Design solution

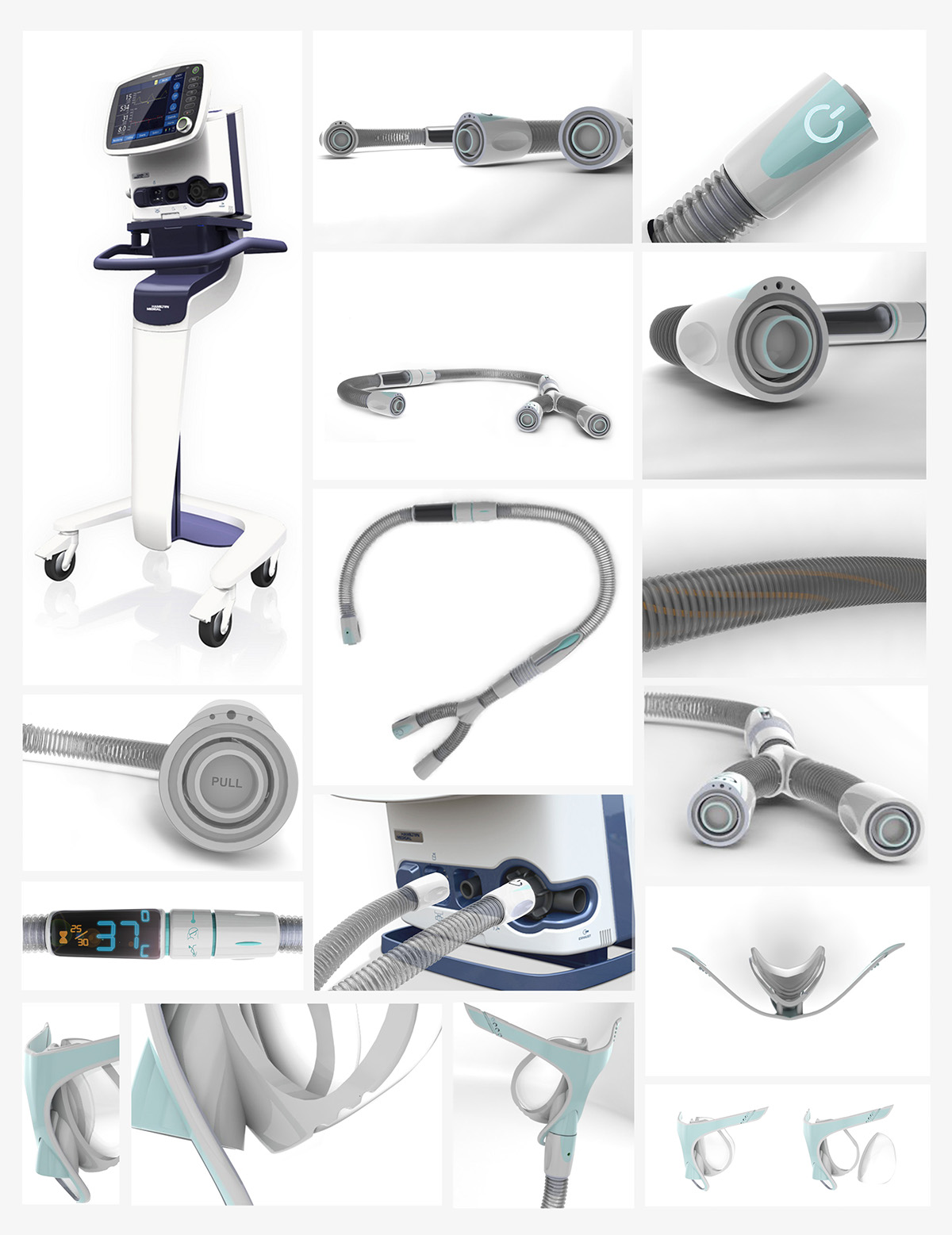

Humidifier and complex connection tubes

The Core of the humidification system starts with the “super/smart circuit”. This effectively replaces the previous “ heater base” and its complex “consumables” by morphing them together into one single tangible product.

When attached to the required ventilator and power source, the circuit will to condition the gasses that get feed to the patient with the advantage of a cheap/energy efficient wicking system (10 times more energy efficient than previously used).

When the pipes feeder tube is attached to a drip source, and the primary circuit is connected to a vent. The pressure of the vent allows water the vapor process to begin and hence condition the gasses to the patient.

Other advantages that the super circuit has over the previous design include:

- One circuit for all: All 6 therapies can now use one standard configuration tube.

- Plug n Play pre assembled Circuit tubing : Nurses don't have to “assemble” the circuit, as its pre assembled at the end of the production line and ready to use.(hence no dangerous medical errors on setup).

- Tubing life span is increased from 7 days to a maximum of 30 days per patient.

- Integrated adaptable circuit connections: Allow the circuit to be compatible and connect with all related competitor products, via adaptable ends using 3 various set radii.

- Gradual heating coil: Allows the gases in the tube to heat up on the last few inches of the tube, hence condensation doesn't have to be controlled throughout the tube which effectively eliminates condensation

- 3 point tactile switch : To quickly switch between therapy modes and customize tube temperature, for patient comfort via L.E.D paper temp and duration display.

Oxygen Mask

Because the mask plays such a vital role in the patients therapy experience, It was essential to improve the function of the mask in relation to the user.

Innovations include:

- Winglet feature: Ensuring that the masks straps never touch the patients facial area hence eliminating the possibility of skin decay and sores.

- Slim fit + Light weight + Nasal cushion: Physical comfort as well as the experience of claustrophobia is vastly improved with the help of a light weight, slim fit design and nasal cushion. This means that the mask now starts at ones nostrils instead of unnecessarily covering the entire nose, as its only nostril exposure thats important. This also means that the patient now has a non obstructive field of view. This also helps to eliminate infamous "dead space" which contributes to condensation in the mask.

- Transformable masks: Practically two masks in one. With the majority of patients on humidification therapy being downgraded from ICU wards to general wards during the final stage of treatment, patients will now be able to continue using the same mask, instead having to change from a sealed mask to a new general (unsealed hudson mask). This is achieved with the mask effectively transforming, as its pressure seal can be removed, technically transforming it into a new non sealed general hudson mask. This not only increases the masks life span but also means that hospitals no longer have to use two different types of masks (sealed and unsealed).

- Vent holes shifted to edge of mask: Helping to reduce the feeling of claustrophobia and a hot and stuffy mask environment, vent holes on the mask which are usually located near the nasal area, have now been shifted to the edge where the mask meets the patients cheeks. This allows for a small amount of external air to enter the mask and brush past the patients cheeks when inhaling, to help give the perception that the mask is environment is cooler with the addition of fresh air.

- Enhanced sport aesthetic: The masks invasive aesthetic has been ditched for a sportier aesthetic, performance products i.e that of high quality sport masks are designed to enhance the users appearance, hence for onlookers (i.e family) the perception of a confident, sleek and performance aesthetic contributes to the perception of confidence and improvement.

Education and Packaging

Instead of using a plastic bag with all the vital system consumables shoved into it, everything is carefully combined into a well designed educational package. The package seeks to add value and substance to the disposable components.

Innovations include:

- Easy instructions: The packaging helps to educate nurses/caregivers about the correct method of use for the system. From the original systems 15 step setup for 6 different therapies, to its new and improved simple 5 step plug and play process. Real time photographic instructions are used to help relate more clearly to caregivers and hospital staff.

- Real time Hero scene display: Displayed on the cover, is a real time photographic image of the “hero image” or final required setup scene. Everything in the hero image can be used as a reference when completing the required setup. All devices used in the “setup scene image” will be of the exact devices used in the hospital of that particular country/market.

- Education: Displayed on the back of the package, is an education diagram, which aims to educate nurses/ caregivers on in depth and important features of the product. This is in an attempt to eliminate the need for Fisher and Paykel to send sales Reps to hold long and expensive training sessions with hospital staff.

- Sealed ends: Lastly, an additional benefit of the new packaging system, is the incorporation of sticker seals on the exposed ends of the circuit tubing components. This prevents the common issue of the entire packages content being simultaneously exposed in one go by air born contaminants ( after a package is accidentally broken or when a nurse opens a package in search for additional parts ).

Project planning Gant Chart

Cognitive Task Analysis

Competitive product surveys & End user profiles

Organic Form Study and Implementation

2D Mask Conceptualisation

3D Modelling Mock up and testing

Gold in Best awards 2011