Staples Global EcoEasy Challenge

Spring 2010

Team Members: Griselda Cardona, Maha Haji, and Sarah Thornton

I had the opportunity to participate in the Staples Global EcoEasy Challenge and was a member of the team that placed First-Runner Up in the competition, winning a $5,000 prize and the possibility that Staples will produce our product commercially. The goal of the competition was to develop a business or home office product that allows users to work more easily and in a manner that is more environmentally responsible than existing similar products.

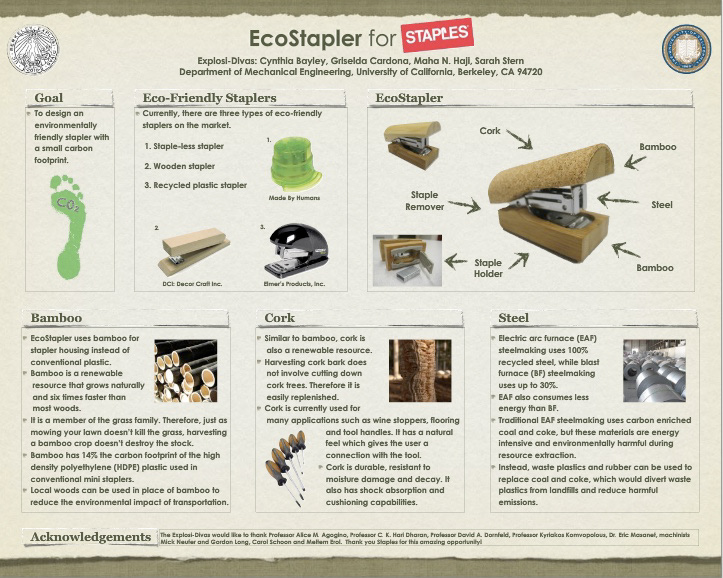

My team, the Explosi-Divas, designed the EcoStapler, a redesign of the conventional stapler. Our concept comprises of three main materials: bamboo, cork, and steel made by an electric arc furnace (EAF) using waste plastics and rubber.

For the finalist event in New York, we manufactured five working prototypes of the EcoStapler. In addition, we considered the environmental impact of our product when compared to a conventional stapler made with high-density polyethylene (HDPE). We examined the use phase benefits and end-of-life considerations of our design. As our design replaces the conventional housing of a stapler made with HDPE with one made with bamboo, we conducted an initial step to completing a Life Cycle Assessment comparing these two materials.

We competed against seven other teams from Australia, Brazil, Germany, and India and placed First Runner-Up in the competition.

Here are a few links with more information about the competition.

Press release:

http://www.me.berkeley.edu/announcements/explosi-divas.html

http://www.businesswire.com/news/home/20100420007033/en/Staples-Announces-Winning-Team-Search-Green-Office

You can watch a video about the competition here:

http://www.youtube.com/watch?v=dGKzISrEd5Q&feature=related

Customer & User Needs Assessment:

Before submitting our concepts to the competition, we conducted an online survey focused on office products. We discovered that staplers are in fact the most widely used office product of those surveyed and therefore present the greatest opportunity for innovation concerning sustainability.

We then conducted a survey specifically about staplers and used this information to determine the most important features that would govern our design. We determined that our design should possess durable and portable characteristics as well as be able to compete competitively with other staplers in the market.

Prototyping:

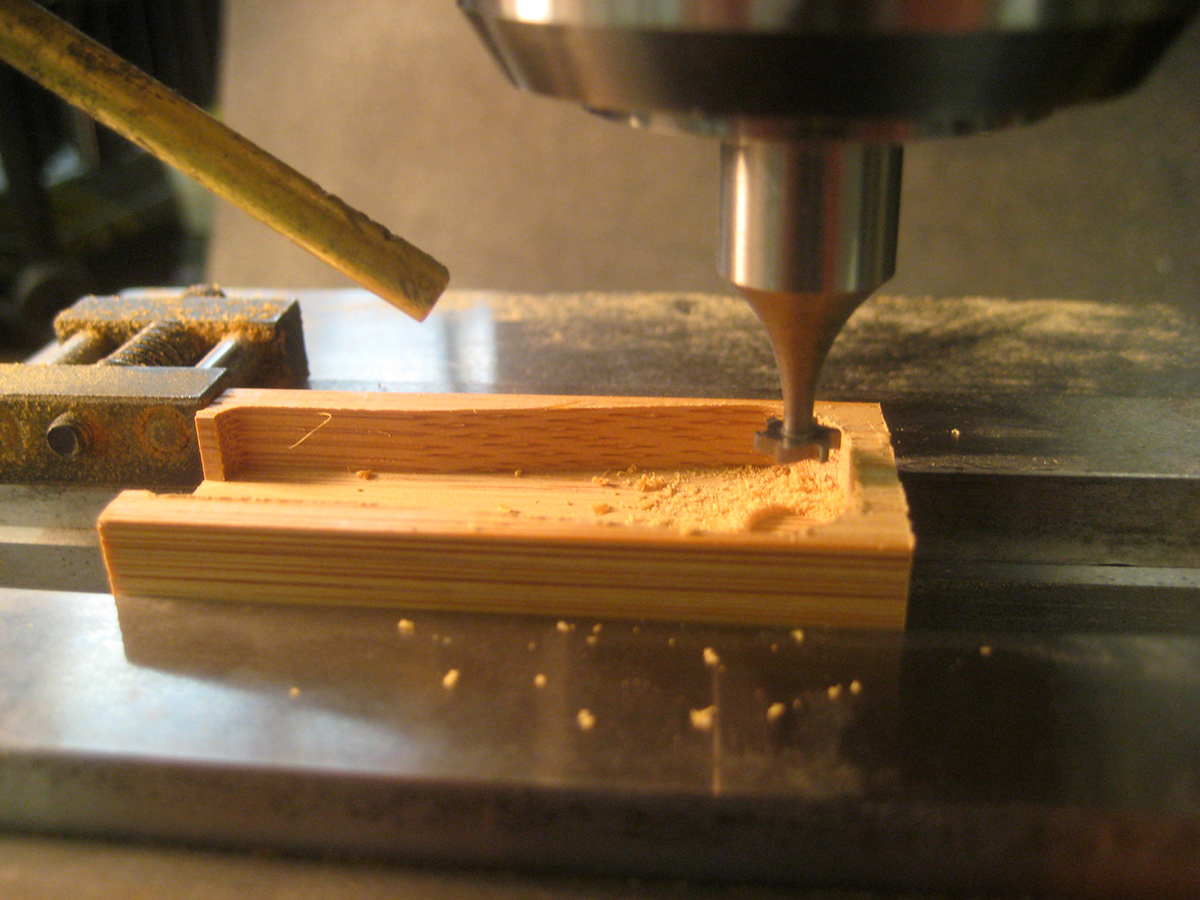

We then benchmarked our design and researched the properties of our materials of choice. We began the process of prototyping our design by first creating a few low fidelity prototypes using materials such as cardboard and clay. Then, in an effort to develop some working prototypes, we invested some quality time in the machine shop. By the time we traveled to New York to compete in the finalist event, we had created five working prototypes. Below are a few photos of the experience. As many of my friends know, I love taking pictures of the complete process and it was rather difficult for me to select just these few.

Low Fidelity Prototyping:

We then benchmarked our design and researched the properties of our materials of choice. We began the process of prototyping our design by first creating a few low fidelity prototypes using materials such as cardboard and clay. Then, in an effort to develop some working prototypes, we invested some quality time in the machine shop. By the time we traveled to New York to compete in the finalist event, we had created five working prototypes. Below are a few photos of the experience. As many of my friends know, I love taking pictures of the complete process and it was rather difficult for me to select just these few.

Low Fidelity Prototyping:

High Fidelity Prototyping:

Concept renderings using Solid Works.

Prototype early and often

Environmental Assessment:

Our initial efforts to evaluate the environmental performance of our re-design was to compare the embodied energy of HDPE and bamboo to determine whether the re-design represents an environmental performance improvement.

Our initial efforts to evaluate the environmental performance of our re-design was to compare the embodied energy of HDPE and bamboo to determine whether the re-design represents an environmental performance improvement.

Representatives of the First, Second, and Third Place teams.

Off the New York! The Explosi-Divas: (from left to right) Cindy Bayley, Griselda Cardona, Sarah Stern, and Maha Haji

Acknowledgements:

First off I'd like to thank Staples for this amazing opportunity. I hope to pursue a career in sustainable product development and this competition not only provided me with hands-on experience but also enlightened me to the innovations and possibilities that lie ahead.

I'd also like to thank the UC Berkeley ME Department machine shop technicians Mick and Gordon for all their help and guidance working in the machine shop manufacturing the prototypes and Professor Agogino for her mentorship throughout the design process.

First off I'd like to thank Staples for this amazing opportunity. I hope to pursue a career in sustainable product development and this competition not only provided me with hands-on experience but also enlightened me to the innovations and possibilities that lie ahead.

I'd also like to thank the UC Berkeley ME Department machine shop technicians Mick and Gordon for all their help and guidance working in the machine shop manufacturing the prototypes and Professor Agogino for her mentorship throughout the design process.

Also, thank you to Prof. Dharan, Prof. Dornfeld, Prof. Komvopolous, Dr. Masanet, Carol Schoon, and Meltem Etol for their insights and guidance.