SPARC

Angle Grinder Redesigned

Angle Grinder Redesigned

The Problem: The wrong tool for the right job

Tools are designed to be universal, to work in every circumstance equally well. Sometimes the common features of a tool aren’t useful to the task it’s used for.

How can we redesign a power tool to accommodate specific user’s needs?

We met with auto body repair technicians and designed a new angle grinder designed for professional auto body technicians and home enthusiasts.

Tools are designed to be universal, to work in every circumstance equally well. Sometimes the common features of a tool aren’t useful to the task it’s used for.

How can we redesign a power tool to accommodate specific user’s needs?

We met with auto body repair technicians and designed a new angle grinder designed for professional auto body technicians and home enthusiasts.

“I remove the [disc guard], I don’t even bother.... it get’s in the way. ”

“Sure, [discs] break...they don’t hurt. Mostly.”

“Sure, [discs] break...they don’t hurt. Mostly.”

“I need to [change discs] to fit into [small spaces], it takes too long to so I [ use multiple tools with different disc types]”

“I prefer pnuematic tools, because they’re less heavy and bulky. But they’re useless when the garage doesn’t have [an air compressor]”

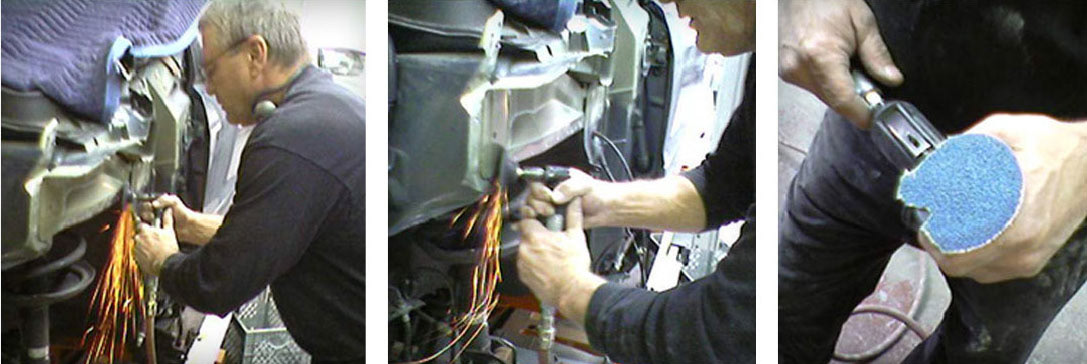

Interviews: Autobody Technicians and Ethusiasts

We watched autobody technicans working and interviewed them about how they used the various angle grinders to do different tasks.

We took away notes full of observations and potential points of improvements.

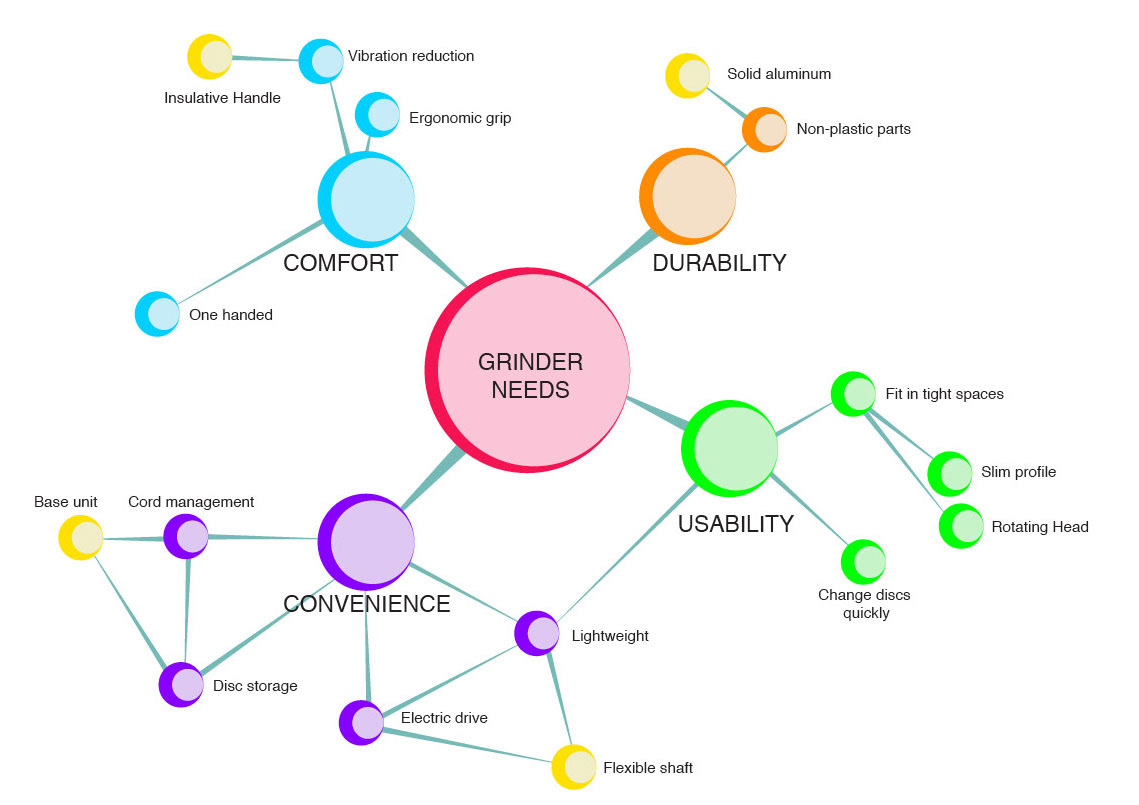

User Needs Mindmap

Mapping the user needs allows us to find new solutions and technologies.

Bulky Electric Motors

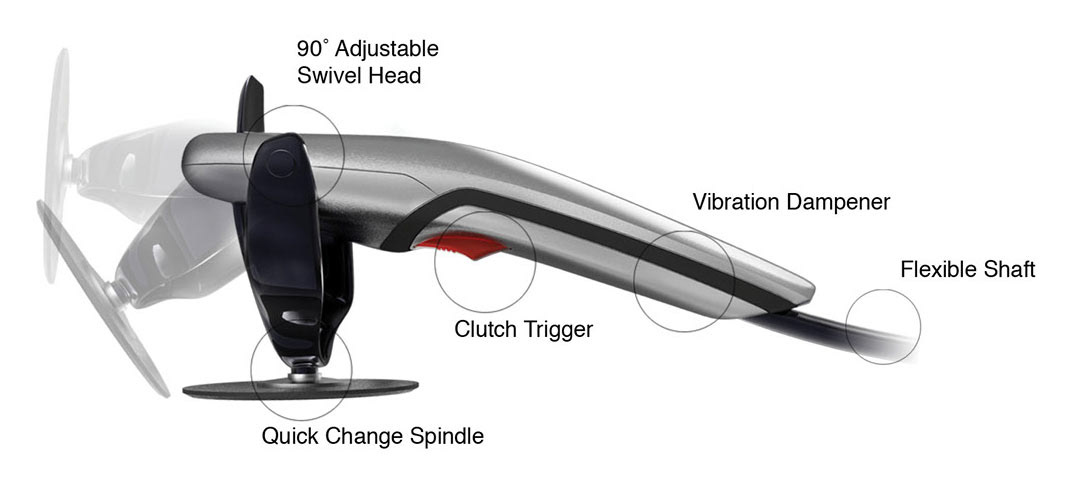

Users had to choose between heavy and bulky electric drive grinders or pnumatic drivers that required a large air compressor to function. By using a flexible shaft we can seperate the motor and the hand piece, creating a lightweight electric drive system.

Cord Management

Pnenmatic tools often had issues with cord management. By intergrating a cord wrap system into the base of the tool we can avoid storage problems.

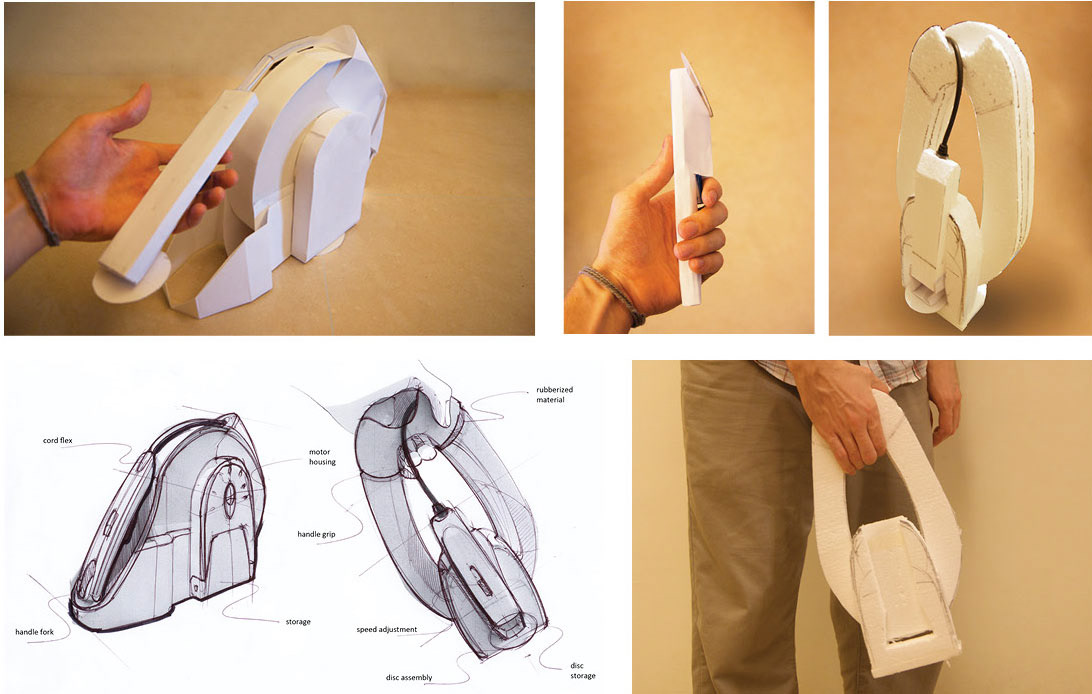

Sketch Ideation

Finding the form

Finding the form

Sketch models

Validating ergonomics and finalizing form.

Validating ergonomics and finalizing form.