For my senior year in ASU's Industrial Design program, I took part in Innovation Space, which is a year long multidisciplinary studio class which groups together students from different majors to work on a sponsored project. Our task was to explore new lighting solutions for our sponsor, Dow Corning.

My group, from left to right: Sean Leoni (Business), Steven Heitzman (Engineer), Justin Holloway (Graphic Designer), and me (Industrial Designer).

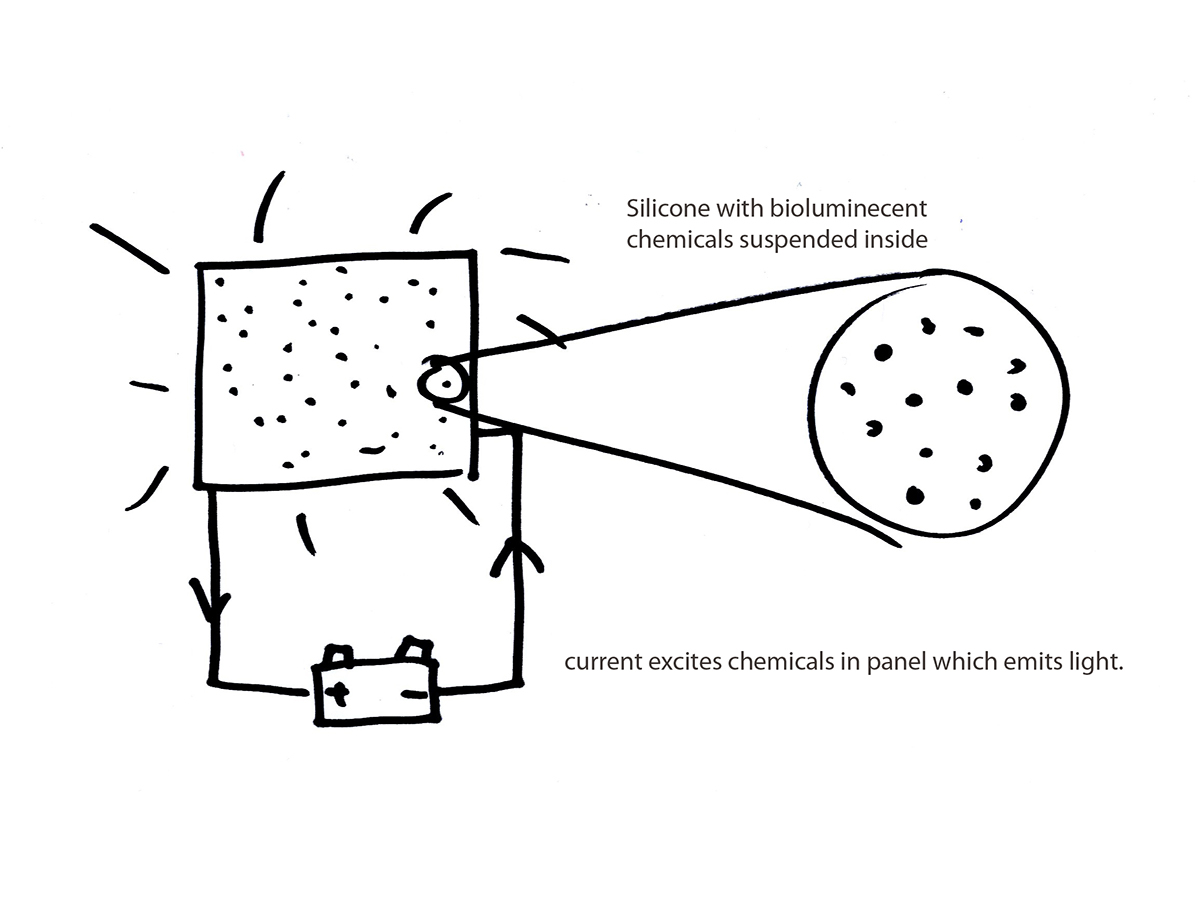

Dow Corning is a combination of Dow Chemical and Corning Glass. They specialize in silicones of all kinds, from adhesives to sealants to optics to lubricants. For this sponsored project, Dow Corning's design brief asked the teams to explore ways to innovate the sustainable lighting market using some combination of LEDs and silicone. We were "to discover the needs of individuals and families in their environments, and find new and innovative solutions that utilize Dow Corning’s silicone materials." We were to explore either home environments, the workplace, or mobile applications.

Research Phase

One of the first things we did was scour the internet for anything and everything on LEDs. We looked at the technology behind LEDs, the principles of creating an effective lighting environment, and scientific research on the physical effects of different types of lighting.

Once we had a foundational knowledge about the topic, we got some LEDs and took them home with us to see how they looked and felt, we interviewed users and asked them about their lighting preferences, and we visited stores to see how their lighting was set up and used on a day to day basis.

We also were able to interview lighting professionals in the areas of LED signage and interior design. We asked them when and why they use LEDs and what factors decide what lighting they use.

Key takeaways:

There aren't really any white LEDs on the market. They are actually blue LEDs with a yellow phosphor overlayed on top, which combines into white light.

LEDs are the most energy efficient consumer lighting source available, and have a much longer lifespan compared to incandescents and CFLs.

LEDs are currently very expensive compared to other lighting types. An LED bulb costs about $40 compared to a similar CFL bulb that costs $3 to $4.

One of the key causes of premature failure of LEDs is that the circuitry gets damaged by the excess heat generated by the diode. Most of the heat is actually emitted off of the back of the unit and is the ideal place for heat sinks. If cooled correctly, they can last 30,000- 100,000 hours.

The common thread through the interviews was that LED are simply too expensive to use in most projects, but in the next couple years they see a turning point where LEDs will become cheap enough to begin replacing traditional lighting.

Ideation

Based on our research, we came up with a list of issues with current lighting and needs of users. We spent the next two weeks as as a combined class brainstorming and coming up with solutions for the previously discovered problems by answering questions like where does light need improvement, how can we bring more light into the workplace, or how can the addition of silicone make lighting better for the user? Different groups put forward different questions and all of the Dow Corning teams worked together to propose ideas.

From the ideas generated, our team quickly sketched out more than 50 different concepts with everything from track lighting that magnetically clamps onto its track, to lighting that memorizes your lighting preferences, to lights with customizable lenses to fine tune color temperature.

Round One Concepts

From these concepts we selected three to refine and present to Dow Corning.

NOVA DYNAMIC LIGHTING SYSTEM - Instead of a rigid polymer optic like most LEDs, the Nova uses a silicone membrane which is able to flex and bows out and retracts when pressure changes inside the bulb using a miniature internal piston. This allows the user to easily switch between flood and spotlight or stop at any point in between in addition to the brightness control that LEDs grant.

ENLIGHTEN - Enlighten is a walkway that uses kinetic energy from people walking on it to power embedded LEDs through piezoelectric technologies. It can store energy during the day and use the piezoelectric currents to sense when people are walking on it at night to light up their path.

LIGHTSTREAM - Lightstream is a concept that uses the light carrying properties of silicone to capture light, boost it with LEDs as necessary, and funnel it into the building though a silicone cable. Once inside, the cables reach a silicone lens which diffuses light into the room, eliminating the need for traditional lighting.

We critiqued the three ideas and then went on to refine the selected concept.

ENLIGHTEN - While it was a cool idea that the average user would instantly "get," we discovered that the idea wasn't original and that it might be a little too simple of an overall idea for a semester long project.

NOVA - The light with a self adjustable beam angle is unique and doesn't exist as far as our research could tell. Our main concerns would be the difficulty of fitting the small pump in a light bulb-sized product.

LIGHTSTREAM - This left us with the central lighting system concept. It was the one that got the most interest at the fall semester show and it had the most potential to be a unique and market changing innovation.

Design Language

Before refining the concept we created three possible form languages to pull from while designing and branding our project.

MODERN SOPHISTICATION - This brand language is designed to fit in with the modern home or office and fade away into the background while the product is not being used. It borrows from Braun and Apple's design language and uses a simple color scheme and a metal finish.

FUNCTION AUGMENTS FORM - Rather than choosing between "form follows function" or" function follows form," this design language combines them by taking the function of the product and celebrates it through its form. Engines and gears are put out for show rather than hidden away. The function of the product is readily apparent because of the chosen form. This is useful for new products that we don't have any preconditioned ideas of how it is used.

FLOWING LUMINESCENCE - This last design language uses the metaphor of blankets of flowing light and applies it to the form language.

Sketching and Study Models

I explored all three of these options through sketching, study models and CAD. We ended up using a hybrid of Flowing Luminescence and Form Augments Function as our form language.

Much of the sketching and concept development at this point focused on the form of solar collection, and the method of distribution.

CAD form development of core unit.

Final Concept

Lightstream is a central lighting system designed to intelligently control a room's lighting from a central location. The light is carried from the central LED unit to the desired location though optically clear silicone cables. Once the light reaches the endpoint, it hits a silicone optic which diffuses the light into the room. Having all the LED lights in a central location means they can inexpensively be controlled by a single small computer that is connected to the building's network and can be programmed and/or controlled directly through any networked device based on the amount of control desired. The high efficiency LEDs are kept cool by internal cooling fans to maximize lifetime and efficiency.

Core Lighting Unit

As the light reaches the end of the cable it is dispersed into the room through silicone optics. We designed two primary optics. One that replaces a standard light bulb/spotlight and one that replaces the standard fluorescent tube lighting will a strip of silicone.

For the end of the semester show we were also required to create a physical model of our concept.