MODS

2018

10 weeks

1st semester MFA, Umeå Institute of Design

single project

1st semester MFA, Umeå Institute of Design

single project

in cooperation with

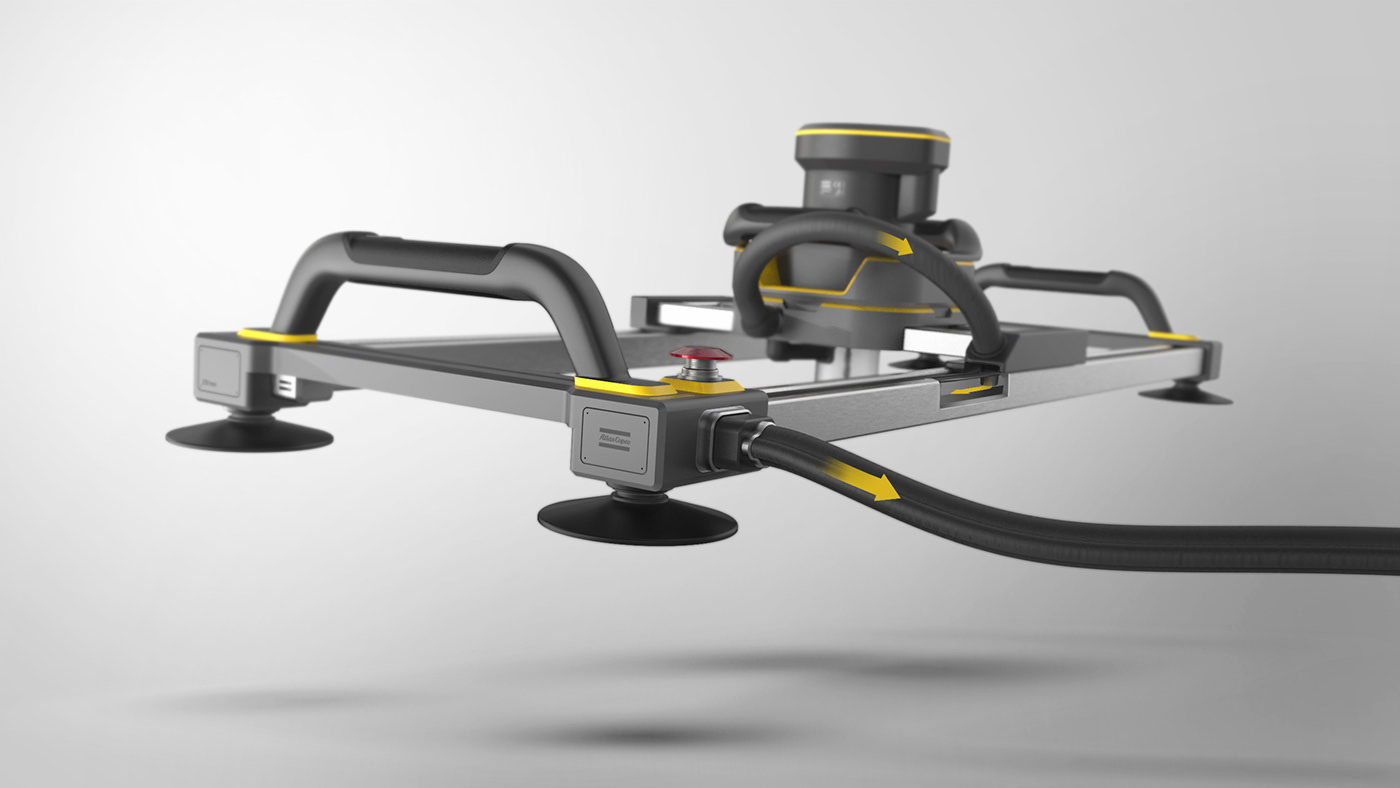

MODS is a concept based on current problems in the aerospace assembly. Based on the research and analysis of the standards and work process right now, the project’s goal was to create a more flexible and smart drilling system for the assembly. The concept adapt’s to different and new working areas while improving the work flow of the operator.

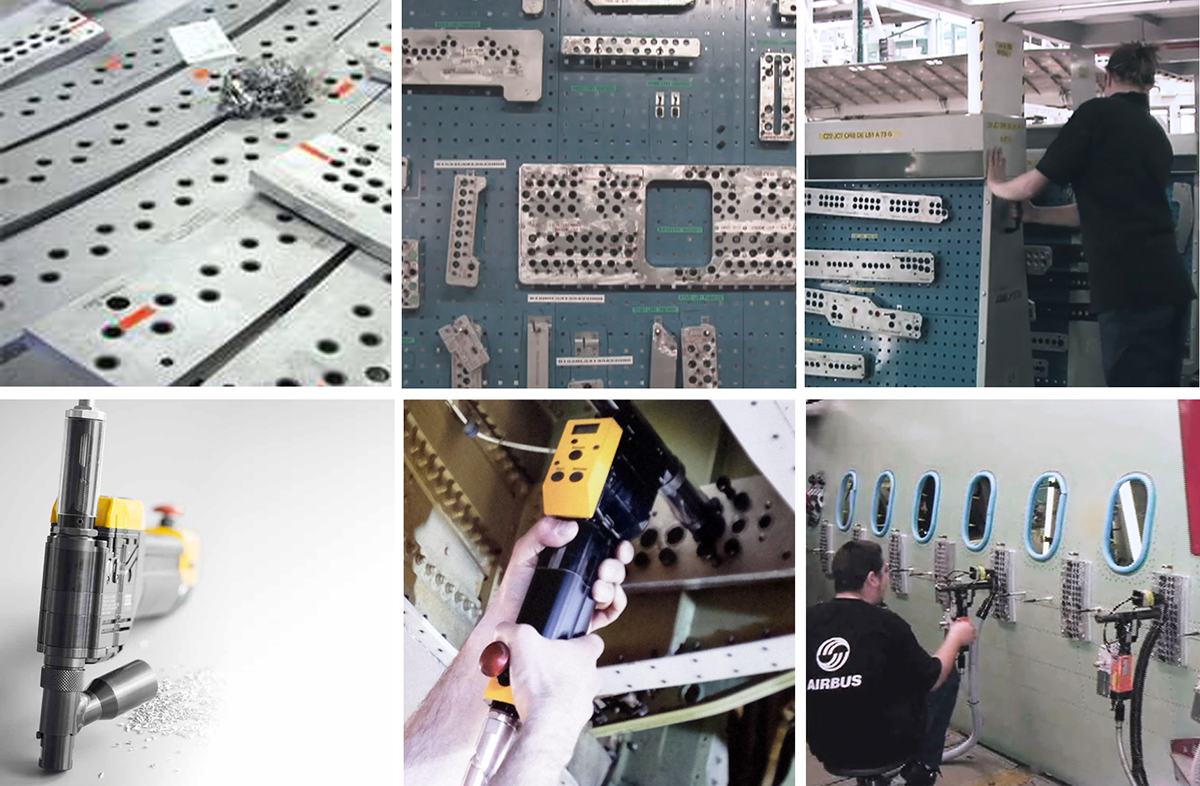

Research trip

Problem

Currently 40% of the drilling in the aerospace assembly is done semi-autonomous, where they use these special drilling templates and Advanced Drilling Unit (ADU’s).

The problem here is that almost every airplane is customized so the templates are specially made for one specific part of the airplane, which is very cost and resource consuming. On the other hand the so called Advanced Drilling Unit (ADU) has to be repositioned for every single hole. This leads to a lot of physical strain for the operator.

Concept

MODS deals exactly with those problems and consists therefore out of three parts.

Flexibility

A simple plug-in system in the adaptive frame makes the entire system more flexible and has the advantage of adapting to different areas.

Chip extraction

With an integrated chip extraction it is possible to lead only one cable out of the system. This makes the handling of the tool easier and more efficient.

Sealing

For an immediate extraction of the carbon fibre fine-dust and a better chip extraction.

Tool change

With a simple swap of the whole spindle the tool change is much easier and more efficient for the operator.

Model making

to find out more check out my website

(link in bio)

Thank you!