FAUKLAND SKØLD

Smurfit Kappa Better Planet Packaging Design Challenge 2019

Isabella Lindblad, Emelie Hörby, Ellinor Frennesson

"According to figures, packaging accounts for almost 40% of the demand for plastic in Europe. Smurfit Kappa is challenging designers, engineers, inventors and creative thinkers, both inside and outside the company, to come up with packaging innovations that will replace the amount of un-recyclable waste generated every year.

Brief: To develop a fully paper-based parcel with thermal protection for chocolates, to use in the eCommerce sales channel."

The current packaging solutions when transporting heat sensitive products are overrepresented of plastic materials such as EPS or cool packs, and are very hard for consumers to recycle in the right way. Therefore we have created a transport box with thermal protection made out of solely biodegradable and renewable materials that does not harm our environment.

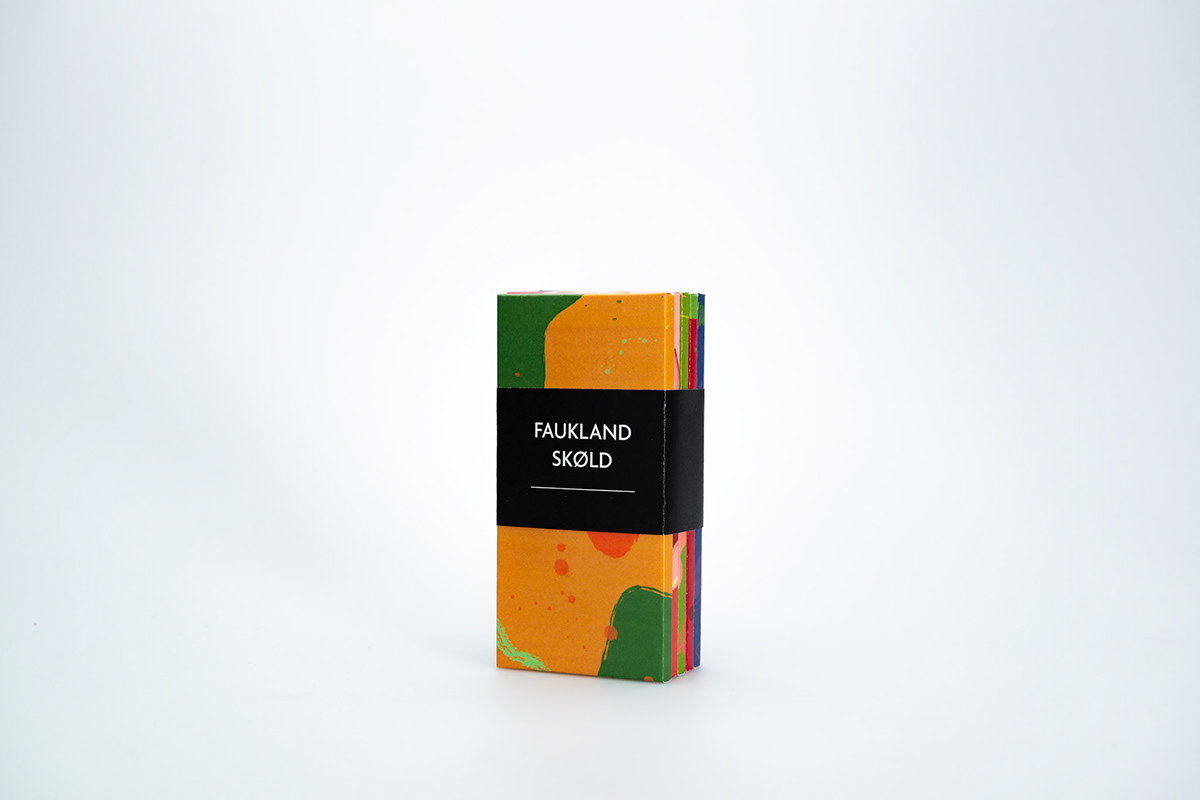

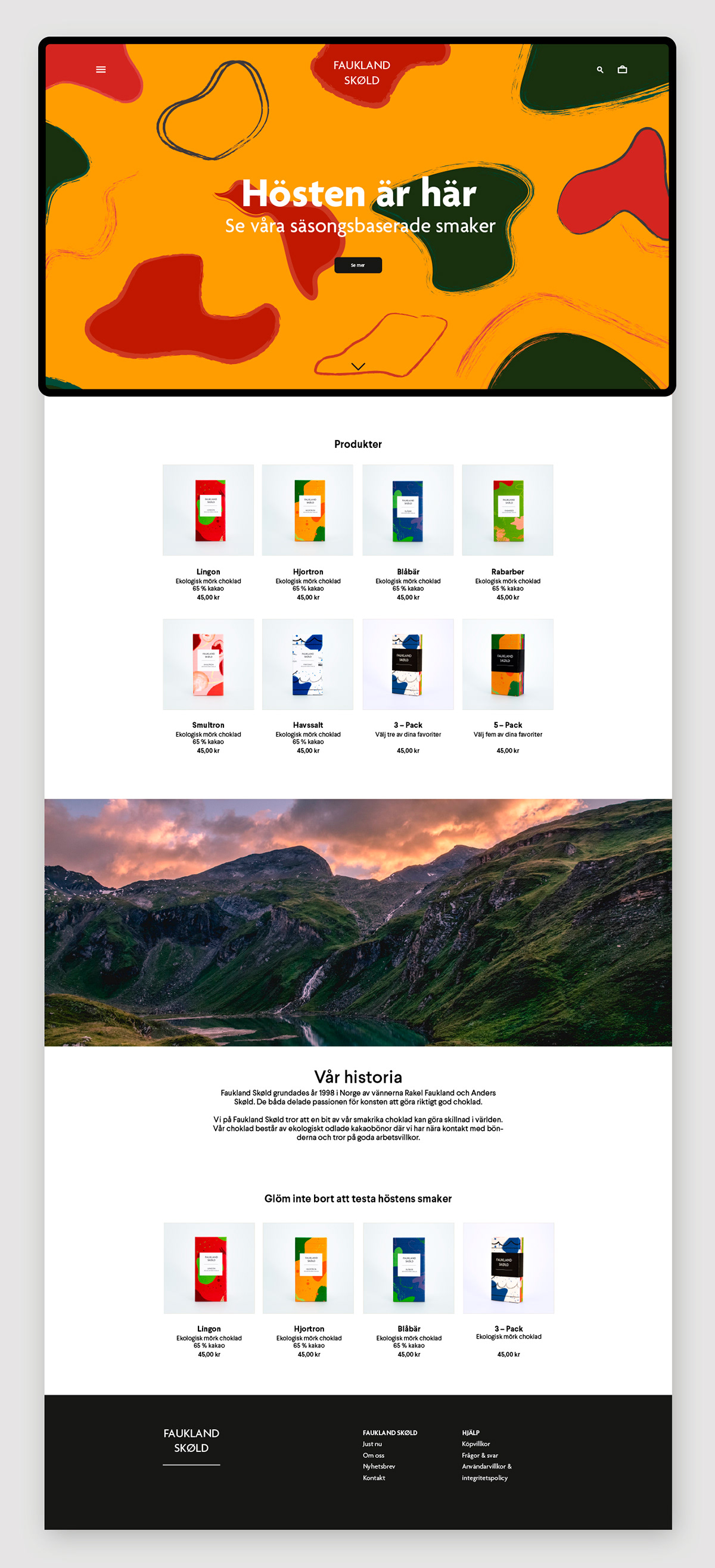

We also wanted to develop an overall concept to produce these solutions, therefore the fictive brand Faukland Sköld was created. A small scandinavian company producing handmade quality chocolate with the ambition of making as little environmental impact as possible.

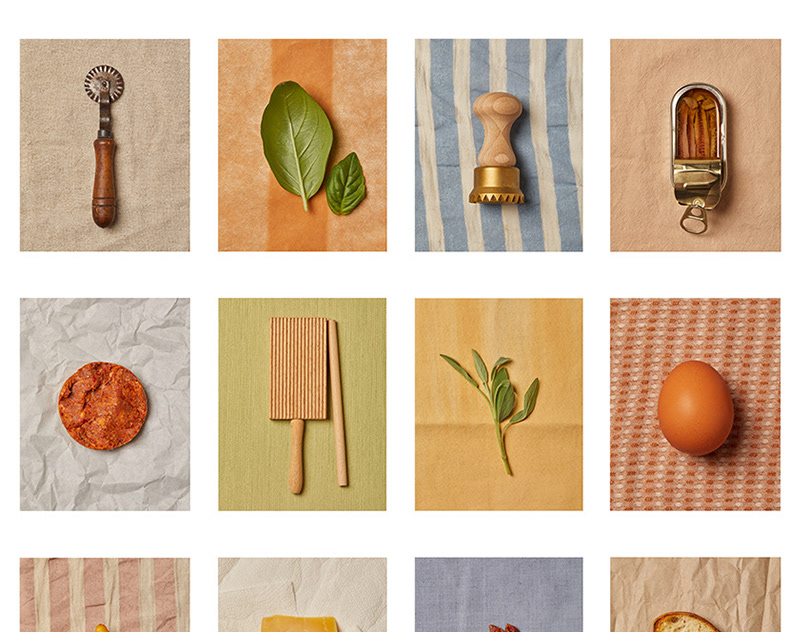

There are packaging for the chocolates with handmade prints, the e-commerce transport box and a mockup for a website made to maintain the brand identity with its playful colors and illustrations, as well easy for the customer to navigate.

Our transport box is made of corrugated paper, since the many layers in the corrugated paper themselves partly prevents the product inside of getting damaged from heat. Inside the box there will be a cardboard construction that has two purposes. Firstly, it holds the product in the right place so that it will not move around and potentially get damaged during transport. It is easy to change the inner measurements of this construction to make it adaptable to any kind of product. In this way, no plastic is needed to protect the product during transport. Secondly, as insulation we are using another reusable material made out of cellulose fibers, which is enough heat resistant for transporting the chocolate on a hot day. It is a lightweight, highly porous material, obtained from Swedish wood pulp

The foam is molded in both the inner cardboard box and in the separate box inside the lid, a two centimeter thick foam that protects the product from heat on every side. The separate box is lying above the chocolate and has the same width as the inner box underneath. This makes the boxes overlap and therefore there are no gaps where the air can get through, and the heat stays outside the box. The foam is not visible for the customer and this renewable and biodegradable material can be kerbside recycled together with the rest of the box, which makes it unique in comparison to the the ones we find on the market today. It is very positive since it will be easy for our customers to be environmentally friendly. In case it is not recycled, it is still less harmful for the environment than its competitors with plastic materials. Since the foam is molded in the boxes there is no glue needed to hold the different parts of the transport box together. The only glue used is on the delivery tag, which also indicates if the box has been opened during transport. In addition, we have chosen to let the box stay white in order to repel sunlight, every detail matters.

Made by Isabella Lindblad, Emelie Hörby, Ellinor Frennesson