Eindhoven University of Technology

Parametric Design Research Project

Aant van der Zee

Processes: Programming, Simulation, Robotics

Team

Elianne Hoogenraad

Nathan Gonsalves

Osman Sümer

Si Chen

Wardah. Hiola

Wenxin Zhu

Yuxiao Wang

Nathan Gonsalves

Osman Sümer

Si Chen

Wardah. Hiola

Wenxin Zhu

Yuxiao Wang

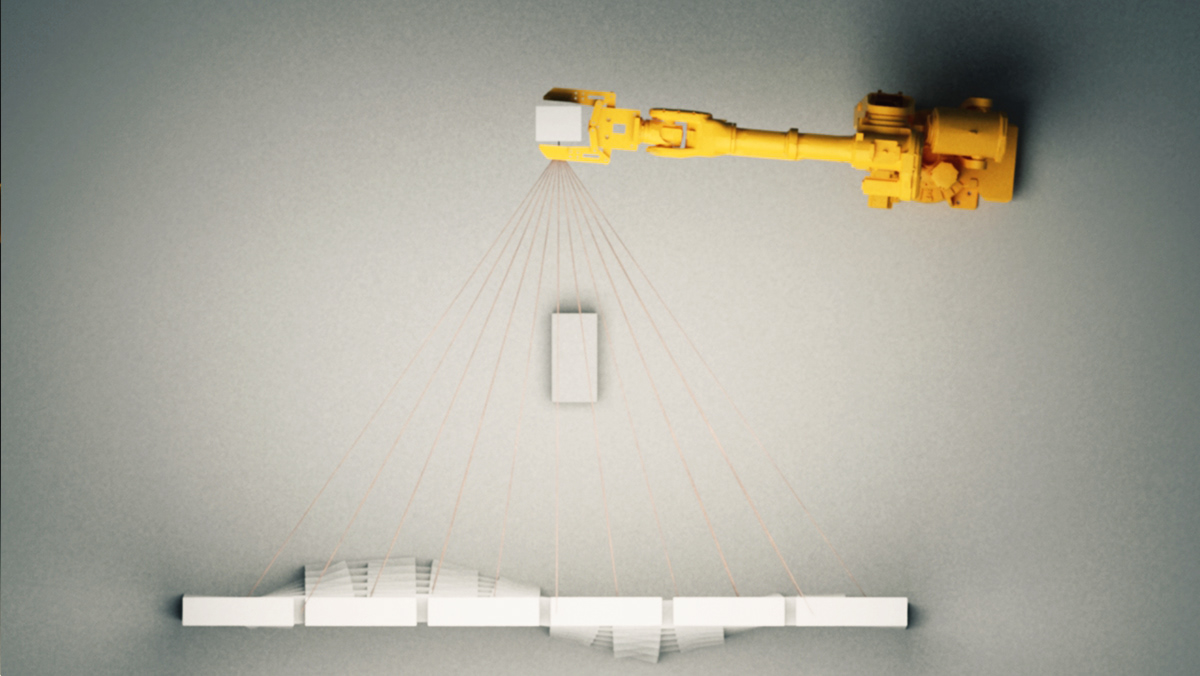

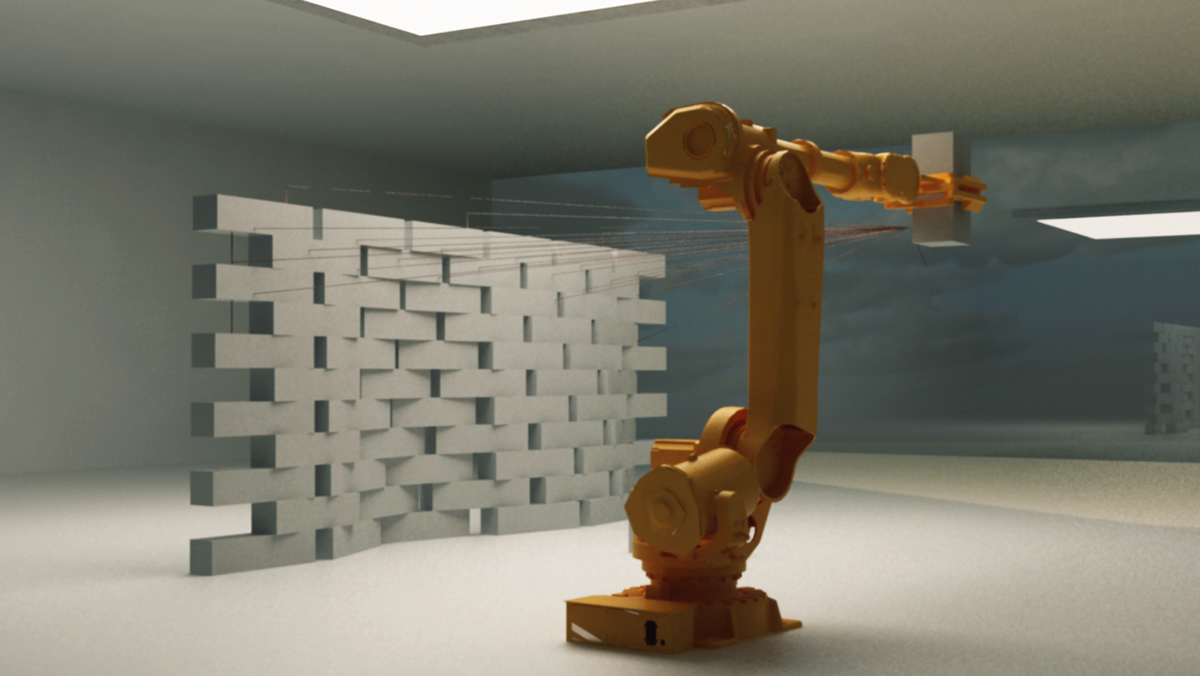

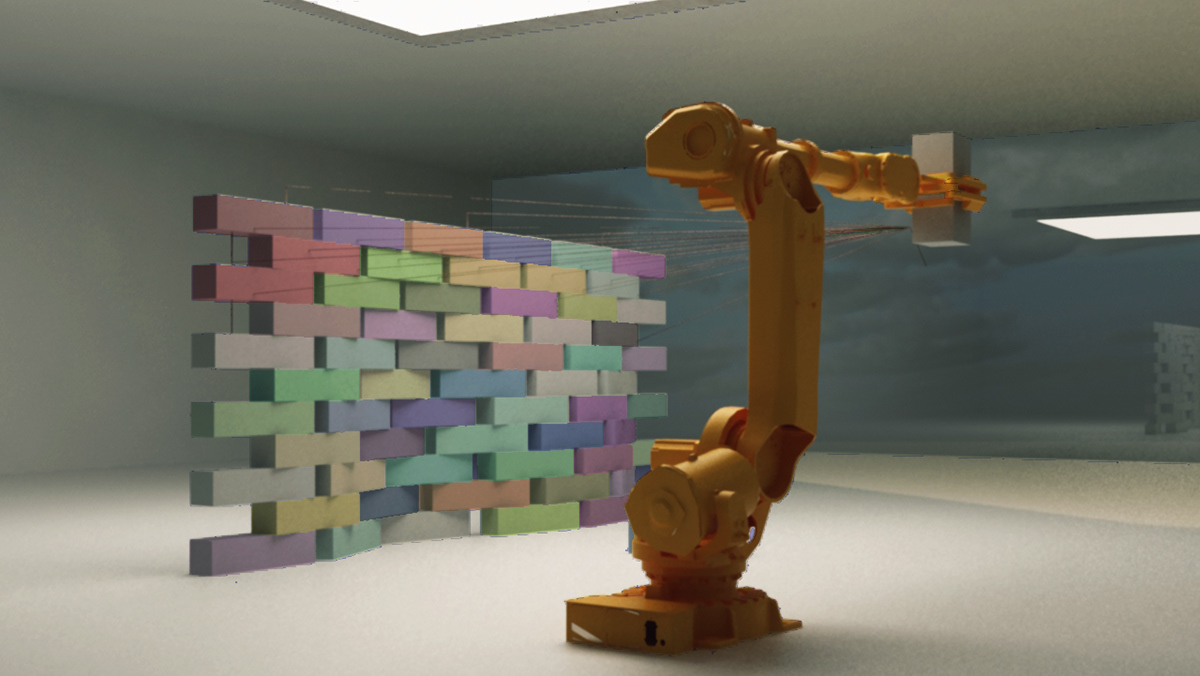

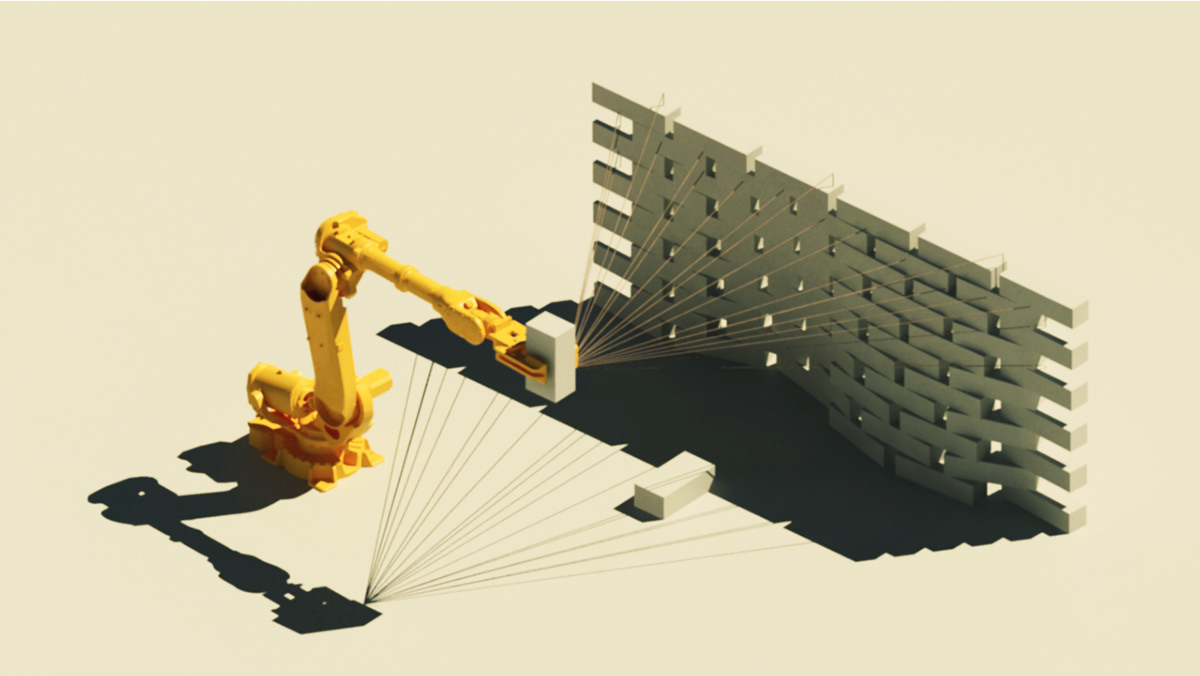

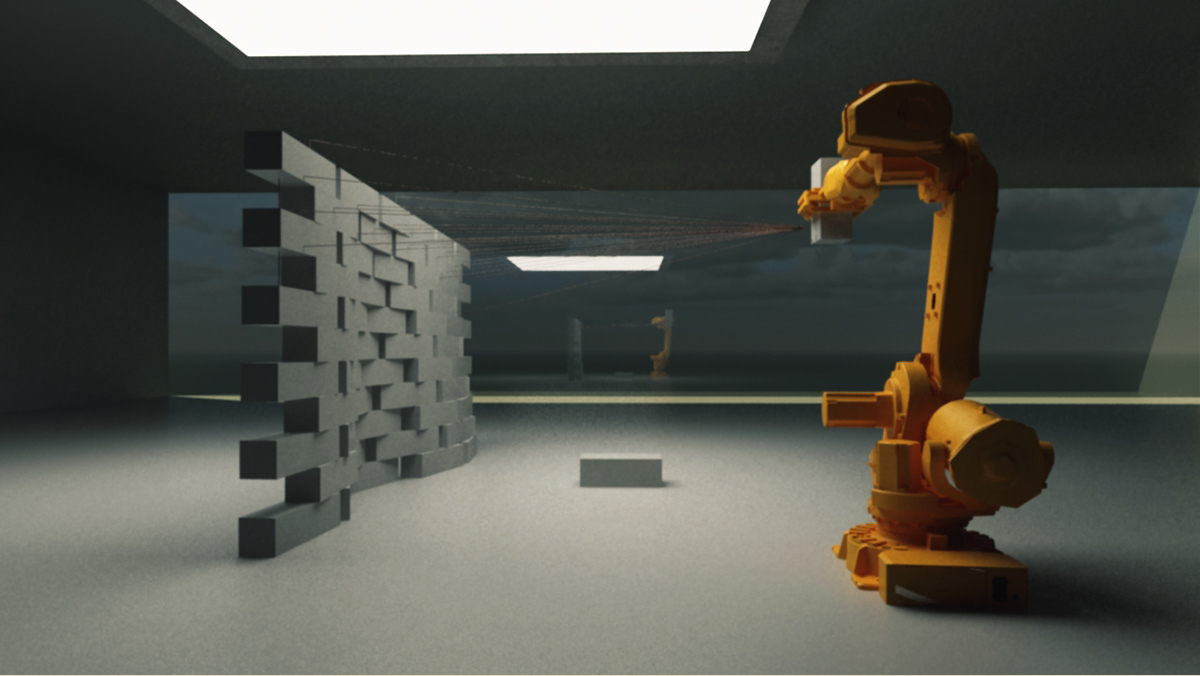

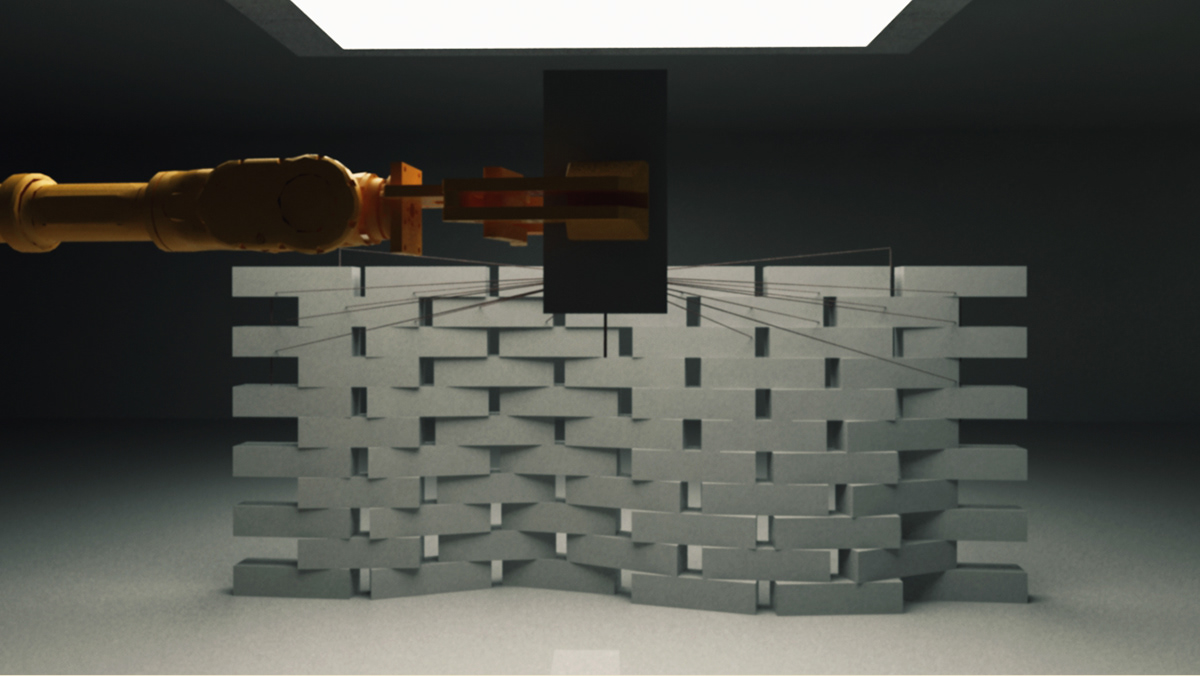

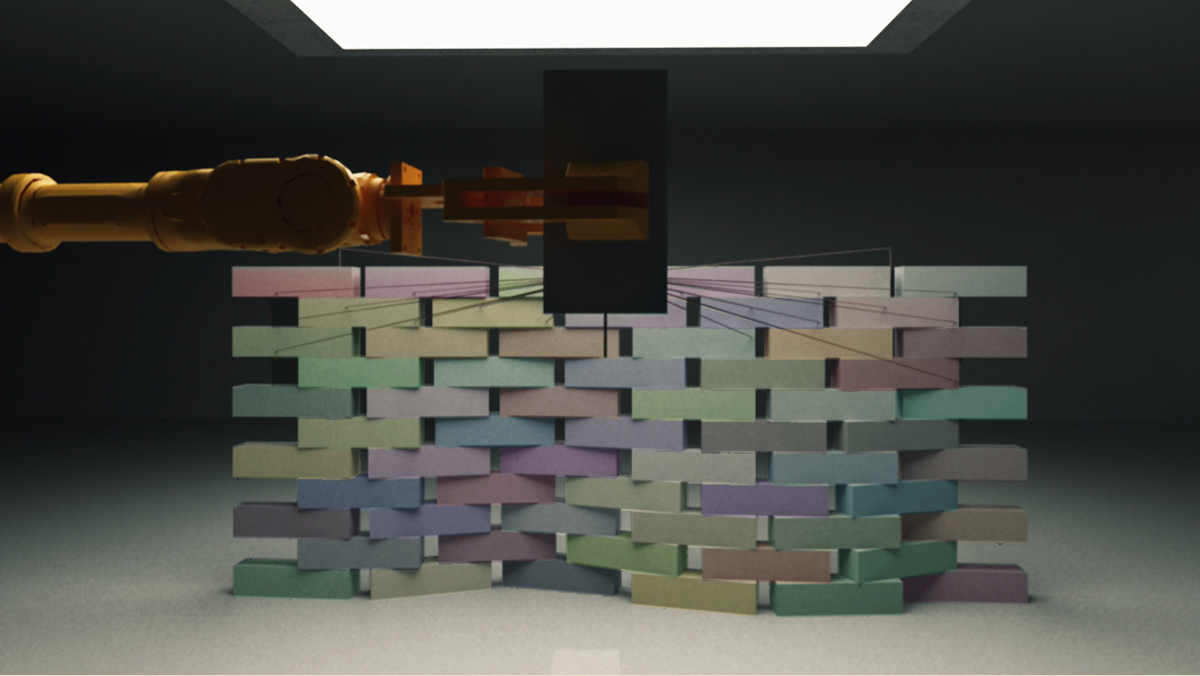

The Robotic Institute of America and the Robot Industries Association defined a robot as a “programmable, multi-function manipulator designed to move material, parts, tools or special devices through variable programmed motions for the performance of variety of tasks” (K.C. Jain, 2001). Simply described, a robot is a machine that is controlled by a computer. A robotic arm is comparable with a human arm. The human arm consists of wrist, with three joints, and the arm itself with two joints, the shoulder and elbow. In total, the human arm has seven degrees of freedom (Harris, n.d.). The industrial robotic arm at the university is the ABB IRB 6650. This robotic arm has six degrees of freedom (6 axis) (ABB, 2004). The robotic arm is therefore comparable with the human arm. The advantages of the robotic arm compared to the human arm is the strength and accuracy (RobotWorx, n.d.).The use of robotic arms is well known in the automotive industry. This industry started using robotics arms from the 1960s (Robotics Online Marketing Team, 2017). The robotic arm with six degrees of freedom provided new opportunities. Nowadays, the robotic arm is used in several industries, including automotive, aerospace, electronics, food and beverage and construction (RobotWorx, n.d.). As a result of the robotic arm, the processes of these industries became more efficient. The robotic arm can be used for many different purposes. The gripper attached to the robotic arm has a large influence on the use. Therefore, the different types of grippers and the consequences for the use will be discussed. In this report, we will consider the functionality of a robotic arm to create a parametric wall. We will create a grasshopper script which allows us to create a virtually robot arm that moves and creates a wall. In this report, we will explain the script of the parametric wall and the translation to the robotic arm.

Axis of the ABB IRB 6650 (ABB, 2004)

Axis of the ABB IRB 6650 (ABB, 2004)

Part 1 - Robot End-of-Arm tool

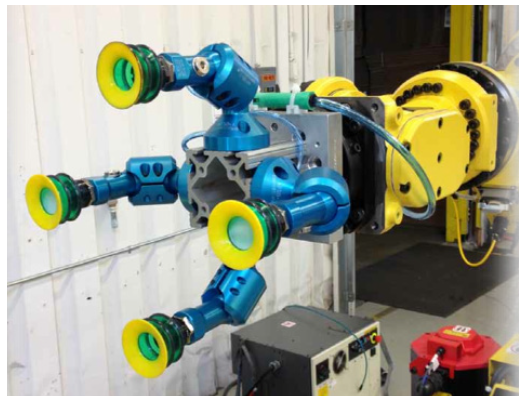

Robot end-of-arm tool is the part that is attached to the end of the robot which performs actions such as cutting, drilling, grabbing or sucking. In the case of our parametric wall, the end-of-arm tool is intended to perform the task of picking up, holding and releasing of the target object. There are various types of tools that may be suitable for this task. The most widely adopted ones are suction system, magnetic system, and gripper system.

The suction system works with a suction cap which is usually connected to a vacuum and using the air pressure difference to suck and release the item. The advantage is that it can grab the object from the top and does not require space between each object when placing. However, the object needs to have smooth surface and in regular shape in order for the vacuum seam to work. Additionally, such system requires a high level of knowledge in pneumatic engineering and requires extensive testing.

Robot end-of-arm tool is the part that is attached to the end of the robot which performs actions such as cutting, drilling, grabbing or sucking. In the case of our parametric wall, the end-of-arm tool is intended to perform the task of picking up, holding and releasing of the target object. There are various types of tools that may be suitable for this task. The most widely adopted ones are suction system, magnetic system, and gripper system.

The suction system works with a suction cap which is usually connected to a vacuum and using the air pressure difference to suck and release the item. The advantage is that it can grab the object from the top and does not require space between each object when placing. However, the object needs to have smooth surface and in regular shape in order for the vacuum seam to work. Additionally, such system requires a high level of knowledge in pneumatic engineering and requires extensive testing.

The magnetic system is widely adopted in metal production industry because of its strong gripping power and can be easily switched on and off through electrical control, but this method is limited to magnetic materials such as steel or iron alloy. In our case of design, we are not intending to use metal to construct the wall, thus this method is not suitable.

The gripper system is the most common and more economical system. There are open source digital models of the grippers from the internet which can be 3D printed and assembled. The actions of the gripper can be controlled either by synchronising it to the robot, or to keep it simple and control through an independent switch. The Below, we will show an example of a gripper that can be used to construct the wall.

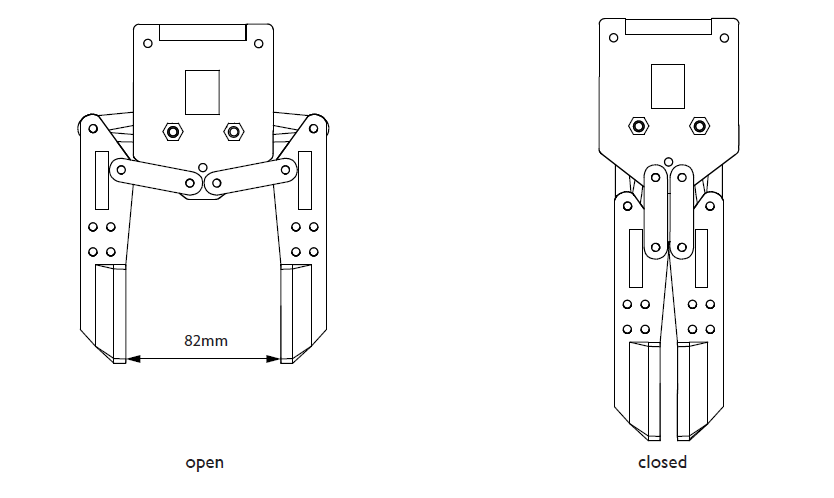

This Medium-Duty Robot Gripper is developed by Mad Mare Studio and the open source is available at: https://www.thingiverse.com/thing:51403. The gripper has two arms, a set of interface links and two drive gears which link the arms to the two servo motor. The torque of the servo motor determines the strength of the grip. The current version supports standard servo motor, which is possible to provide a torque strength of up to 3.4 N.m, which means the gripper will probably be able to carry foam and light timber, but unlikely to handle heavy items such as brick. The maximum opening of the gripper is 82mm. It is possible to enlarge the gripper and install a larger motor in order to carry heavier objects.

Our parametric wall is a linear design. Each block is to be placed next to each other with the long edge of the block aligned with the tangent of the linear curve. Thus, it is ideal for the gripper to catch the longer edges of the brick and leave the short edges free. This way the gripper will not interfere with the blocks that were already in place.