NAIL CLIPPER: Redesign

Design:

Nail clippers are usually made of stainless steel but can also be made of plastic and aluminium. Two common varieties are the plier type and the compound lever type. Most nail clippers usually come with another tool attached, which is used to clean dirt out from under nails. A nail clipper often has a miniature file fixed to it to allow rough edges of nails to be manicured. A nail file allows for removal of any excess nail that is jagged or has been missed. Nail clippers occasionally come with a pocket knife or a nail catcher. The nail clipper consists of a head which may be concave or convex. Specialised nail clippers which have convex clipping ends are intended for trimming toenails, while concave clipping ends are for fingernails. The cutting head may be manufactured to be parallel or perpendicular to the principal axis of the cutter. Cutting heads which are parallel to the principal axis are made to address accessibility issues involved with cutting toenails.

Need for the innovation:

Human nails grow approximately 0.1 mm per day, so nail-clippers are useful in our daily lives. Humans are using nail-clippers or other manicure procedures for very long, but there is not much innovation.

Problems: (Generally, faced by people)

-Skin get chipped with finger nails

-Not easy in terms of force and precision

-Nails have to be filed after clipping

-Wearing-off of metal layer on cheap nail-clippers

-Disposal of nails does not occur at a single place, i.e. the nails keeps getting thrown in random directions on cutting

-Some clippers are too big or too small for everybody’s use

Existing Qualities:

-Familiar to the millions of people, so the technical know-how is a bliss

-They are generally cheap (In India, they start from around 8-10 INR)

-Available almost everywhere

-Claws are in the shape of fingernails

-File is available on the handle

Qualities which can be added:

-The force application and precision of cutting can be improved

-The neck of claws can be redesigned for not chipping of skin around the nails

-Different sort of materials can be used

-Handle/lever can be redesigned with the file

-Better design to dispose of the nails properly in a controlled way

Design explorations: (Line drawing for simplified illustration)

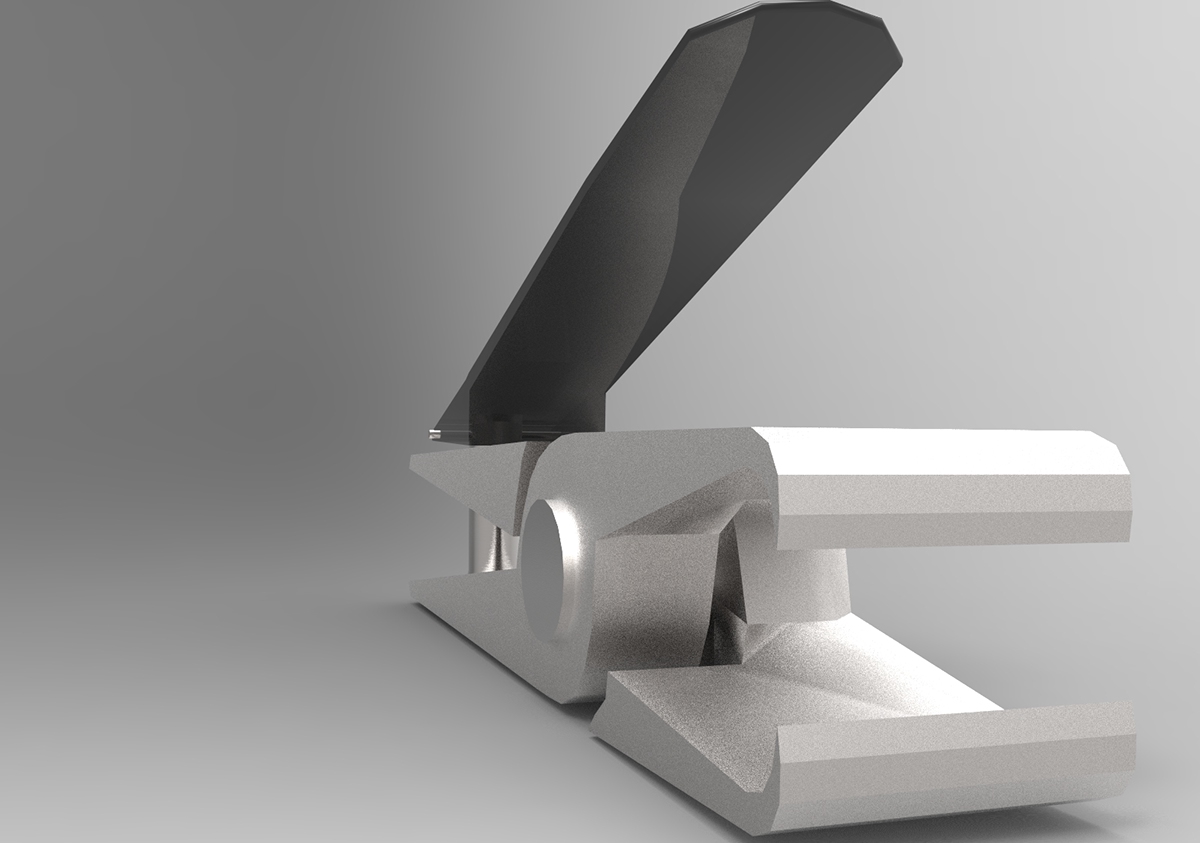

PROPOSED DESIGN:

Details:

-The file will be attached to the handle

-The weight is estimated to be around 30 grammes

-The material used will be martensitic stainless steel, which has a density of 7.78 g/cm3, and is used in surgical equipment

-The curvature radius of claws will be around 10 mm, because the cutting can be done twice for nails with a smaller radius, whereas not the same case for nails with a larger radius. (As the transverse finger nail curvature lies between 4.4 mm to 13.7 mm)

-The blades of claws will be of radius 25 mm inward, following the tradition of the nail cutters used at the moment

Pros:

-The lever is attached to the other side of the body, which increases the precision, control and decreases the amount of force required for the cutting/clipping process of fingernails. (Using the law [F.l=F’.l’], where (F) is a force applied at a distance (l), and the area to apply pressure on the handle will be more because of the inverse kind of set-up)

-It uses both mechanisms, plier and compound lever type

-The claws will be made according to the survey/research done on 300 human beings, and this will enable people to cut their nails in right amount, without damaging their skin

-The curvature chosen for the neck of claws are capable of providing force to cut the nails and not harm the skin while doing so

-The design can be made using different materials for different price ranges. (Stainless steel as for necessity, titanium as for luxury)

Thank you!