RIOT’s task was to produce a control and visualization ICT system for power plant.

Brief

Our task was to design, program, and implement a dedicated SCADA system in order to gather current data from the facility by using PLC drivers connected directly to actuators (connectors) and measuring devices (inter alia electricity voltage, current, and power measuring devices as well as temperature measuring devices), and present it all in a user-friendly form. The system was intended to provide our customer with full control over a critical process, specifically “carburizing”.

Network architecture diagram

project

We were invited to the project by the general electrical contractor.

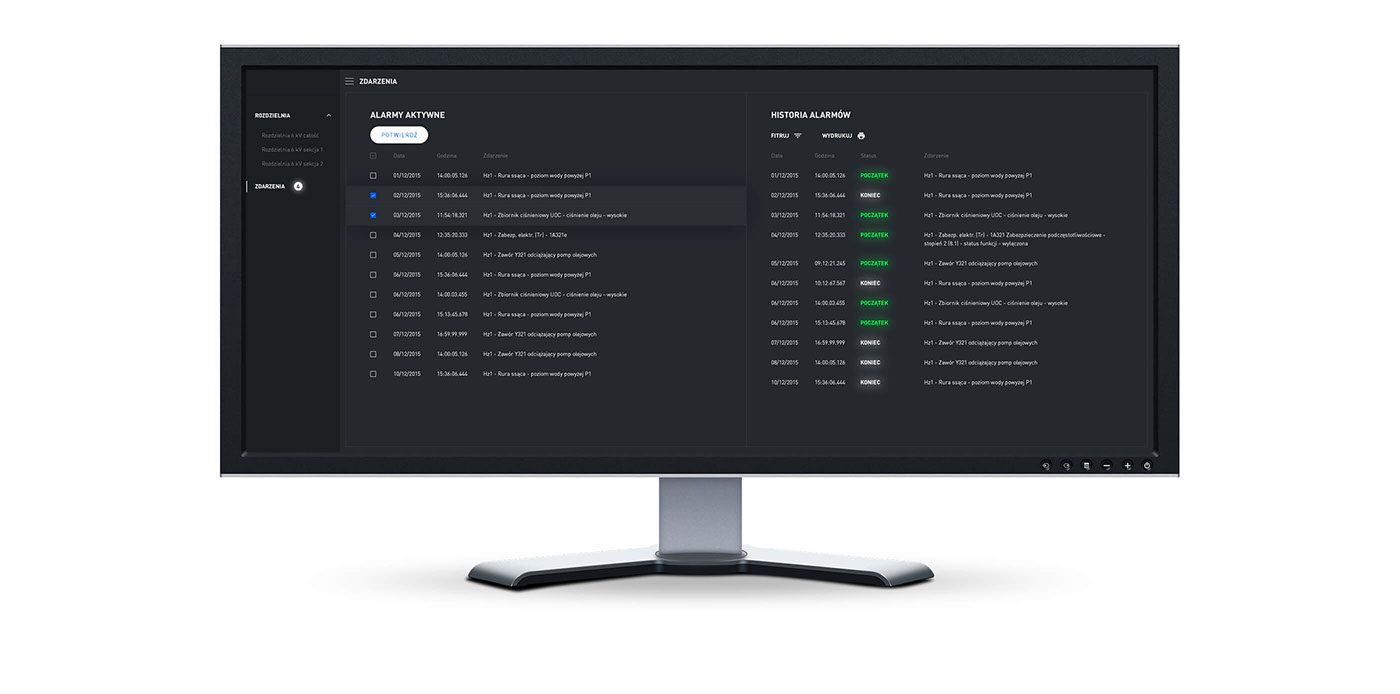

Our work began with redesigning the archaic interface. Interviews with its users allowed us to accurately identify the major flaws in terms of usability. The graphic design was created on that basis and incorporated a number of solutions to make using the system easier, such as a correct color palette, high contrasts, and animations, all designed to facilitate the user’s understanding of the process. In order to make using the system more comfortable, we also decided to change the archaic 17-inch screens to modern 29-inch, ultra-wide monitors.

Our work began with redesigning the archaic interface. Interviews with its users allowed us to accurately identify the major flaws in terms of usability. The graphic design was created on that basis and incorporated a number of solutions to make using the system easier, such as a correct color palette, high contrasts, and animations, all designed to facilitate the user’s understanding of the process. In order to make using the system more comfortable, we also decided to change the archaic 17-inch screens to modern 29-inch, ultra-wide monitors.

After concluding the design, we began the programming work. The characteristics of the project demanded that we use standard client-server architecture. The back-end layer of the system was written based on the Spring (Java) framework, while we used the React (JavaScript) framework for the user interface layer. The application was launched on an operator station in Google Chrome, working in the kiosk mode and we used the ModbusTCP protocol for communicating with the PLC drivers.

The next stage was to build an ICT network which included twenty-six bay units, an operator station, a server, and three switches. We connected all elements of the network with Ethernet cables, twisted pair cables or optical fibers.

Twenty-six bay units

After successful implementation of the network, the time came for testing the system. Apart from functional tests, we verified the system’s response time and the intensity of light in the optical fibers. Results of the final test met all the norms included in the tender documentation.

effect

Working on the system, together with preparing full post-completion technical and maintenance documentation, as well as conducting training for the staff, took ten months. In that period, we were able to significantly improve the aesthetic and functional qualities of the platform and also reduce its failure frequency. Currently, the system is fully functional and in use at the power plant.

RIOT will further develop the system by following various elements in accordance with the ongoing development of modernization works.

RIOT will further develop the system by following various elements in accordance with the ongoing development of modernization works.

Location

Kraków, + Katowice, PL.

Team

+ RIOT: UX designer, UI designer, back-end developer, front-end developer, computer engineer, project manager;

+ SJEnergia: electricians, builders;

+ JMTronik: project engineer.

Scope

Equirement analysis, UX design, UI design, back-end development, front-end development, computer engineering, quality assurance, project management.

Timeline

December 2015 → September 2016.

Workflow

Project executed using the classic waterfall method, inspections of particular stages, site inspections, and meetings with the client.

Toolkit

Photoshop, After Effects, Illustrator, Sketch, Invision, SVG, HTML5, CSS3, Java Script, React, Java (Spring), MySQL, WebSockets, AJAX, Maven, Hibernate, ModbusTCP, Git, Bitbucket, Podio.