Intro

Rapid Manufacturing is a relatively new concept in design, the idea that components and products can be "printed" rather than manufactured. Some hail the technology as the holy grail of product manufacture, others simply a curiosity and nothing more.

Many studies into the merits of the technology have been conducted, but always from a biased view point. This project aimed to answer some of the fundamental questions of whether this technology could ever be used in an automotive application? and if it could, what form would it take?

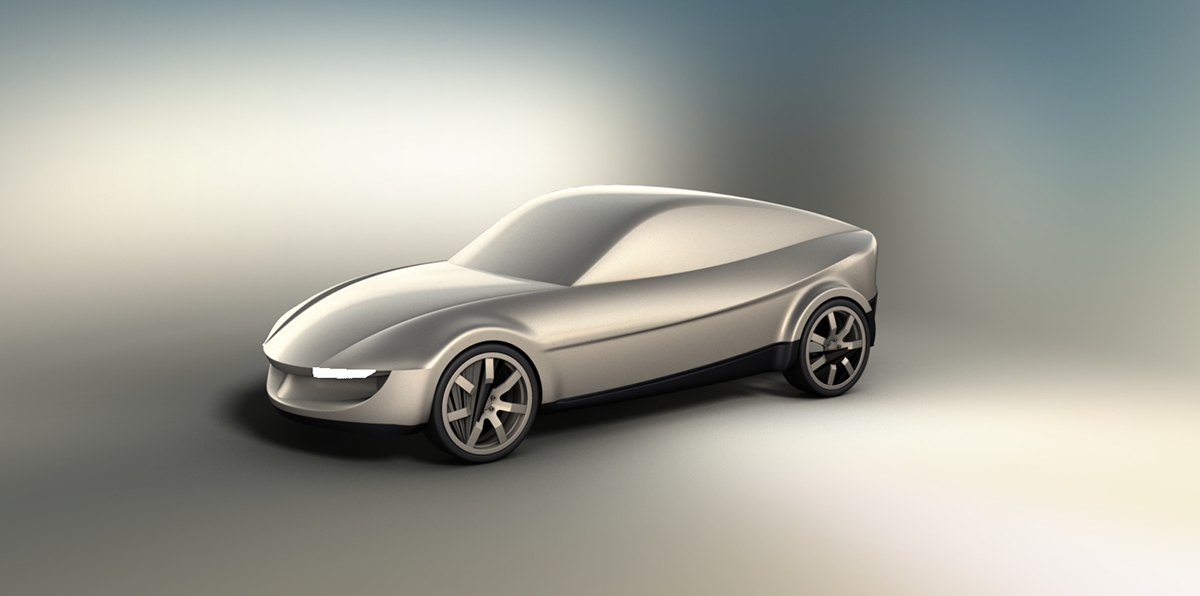

This is Concept Kaizen

Rapid Manufacturing is a relatively new concept in design, the idea that components and products can be "printed" rather than manufactured. Some hail the technology as the holy grail of product manufacture, others simply a curiosity and nothing more.

Many studies into the merits of the technology have been conducted, but always from a biased view point. This project aimed to answer some of the fundamental questions of whether this technology could ever be used in an automotive application? and if it could, what form would it take?

This is Concept Kaizen

Development of a Theme

Before any design work commenced it was important to establish the visual design language of the vehicle. Key themes within the design were the application of technology and the human perception of technology.

CleanMinimalistTimeless

Key words to evoke the values and qualities of a vehicle that is built using cutting edge technology

Project Imagery

Before any design work commenced it was important to establish the visual design language of the vehicle. Key themes within the design were the application of technology and the human perception of technology.

CleanMinimalistTimeless

Key words to evoke the values and qualities of a vehicle that is built using cutting edge technology

Project Imagery

Art Poster

Digitally composed Image In Adobe Photoshop Cs5

Settling on a Theme

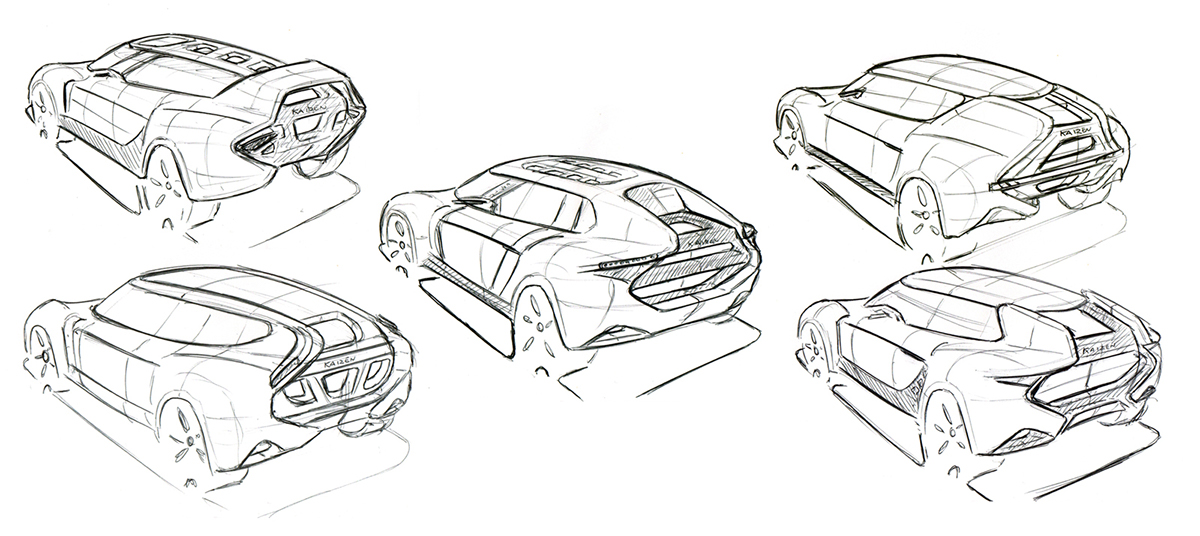

A vehicle that breaks the manufacturing convention needs an exterior to match. The difficulty in this is how far to push the boundaries away from the known conventions. Below are key thumbnail sketches taken from this process, ranging from the clinically pure to the otherwise impractical.

A vehicle that breaks the manufacturing convention needs an exterior to match. The difficulty in this is how far to push the boundaries away from the known conventions. Below are key thumbnail sketches taken from this process, ranging from the clinically pure to the otherwise impractical.

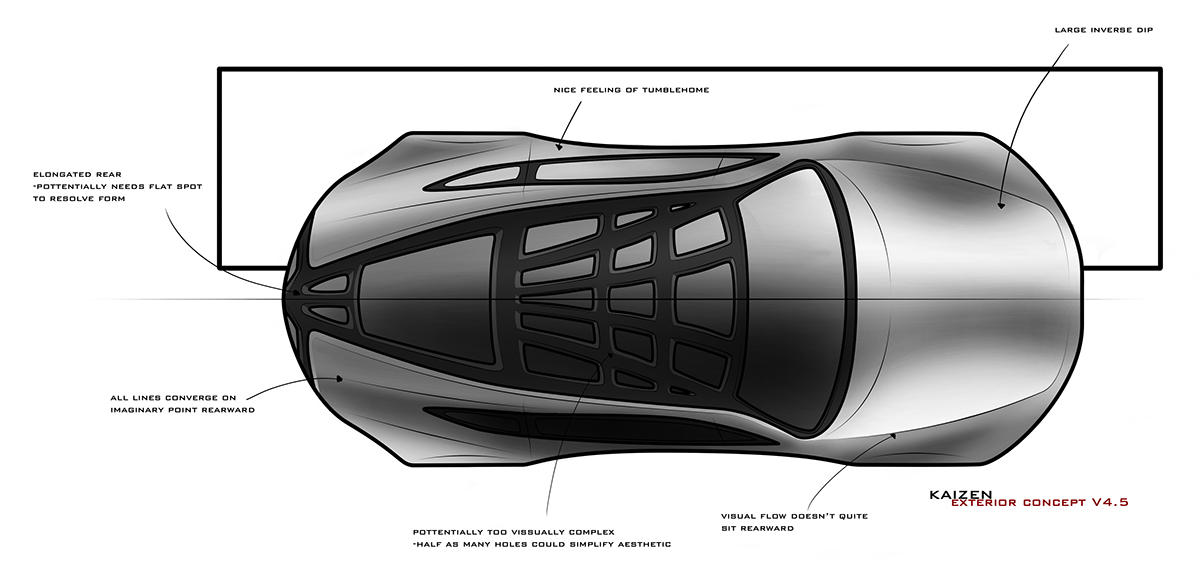

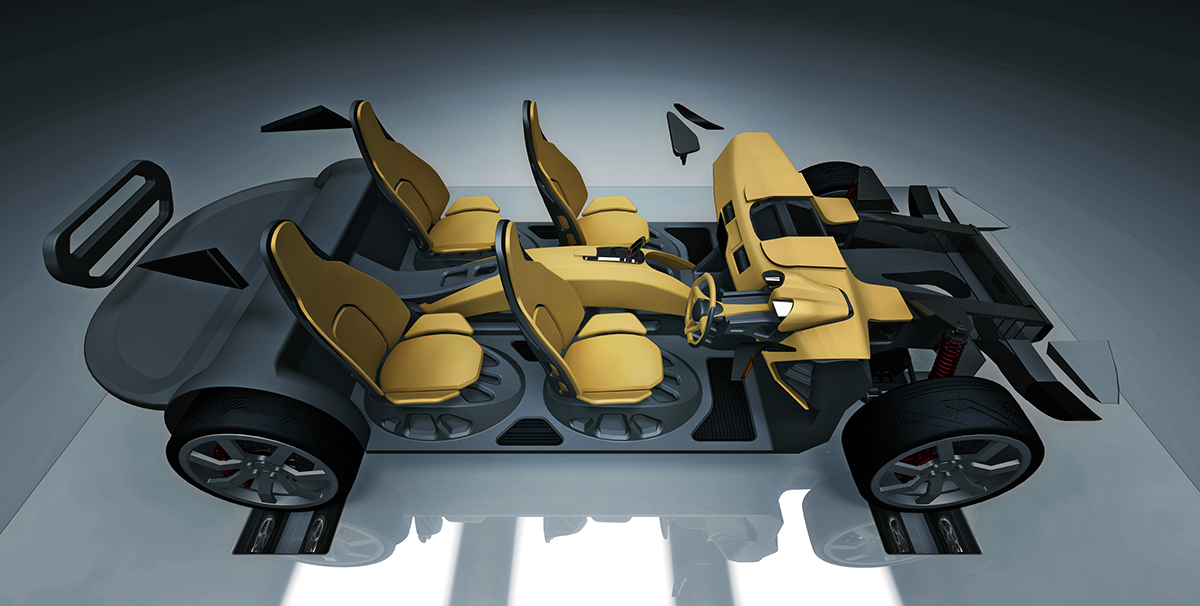

A Direction is Chosen

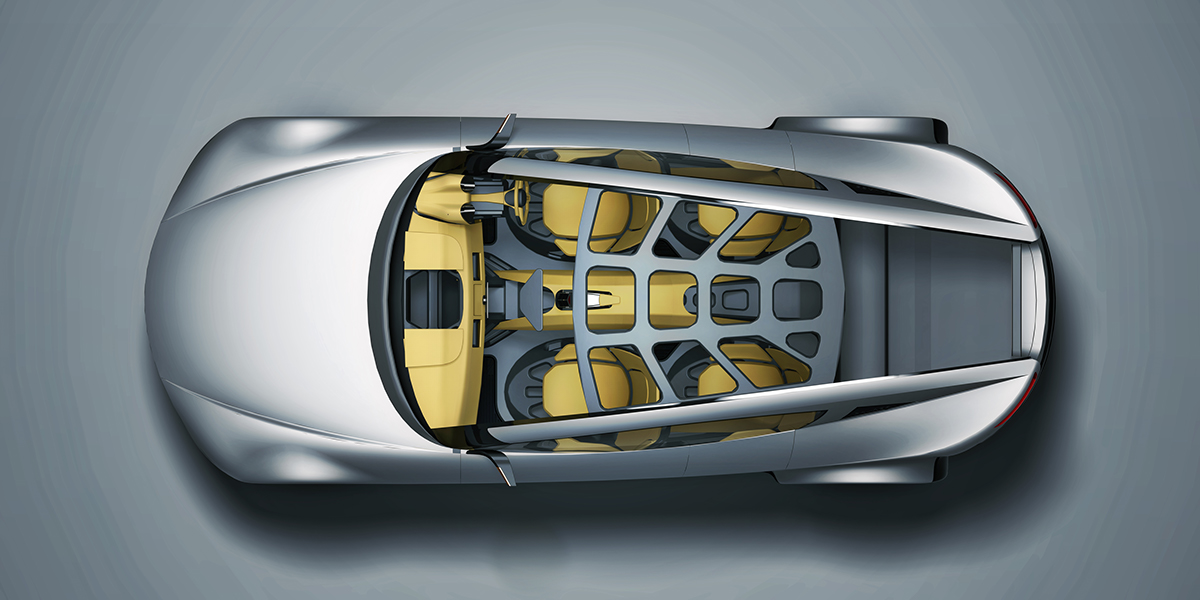

Clean and pure, large DLO graphics exposing the unique Rapid Manufactured Chassis Underneath

Clean and pure, large DLO graphics exposing the unique Rapid Manufactured Chassis Underneath

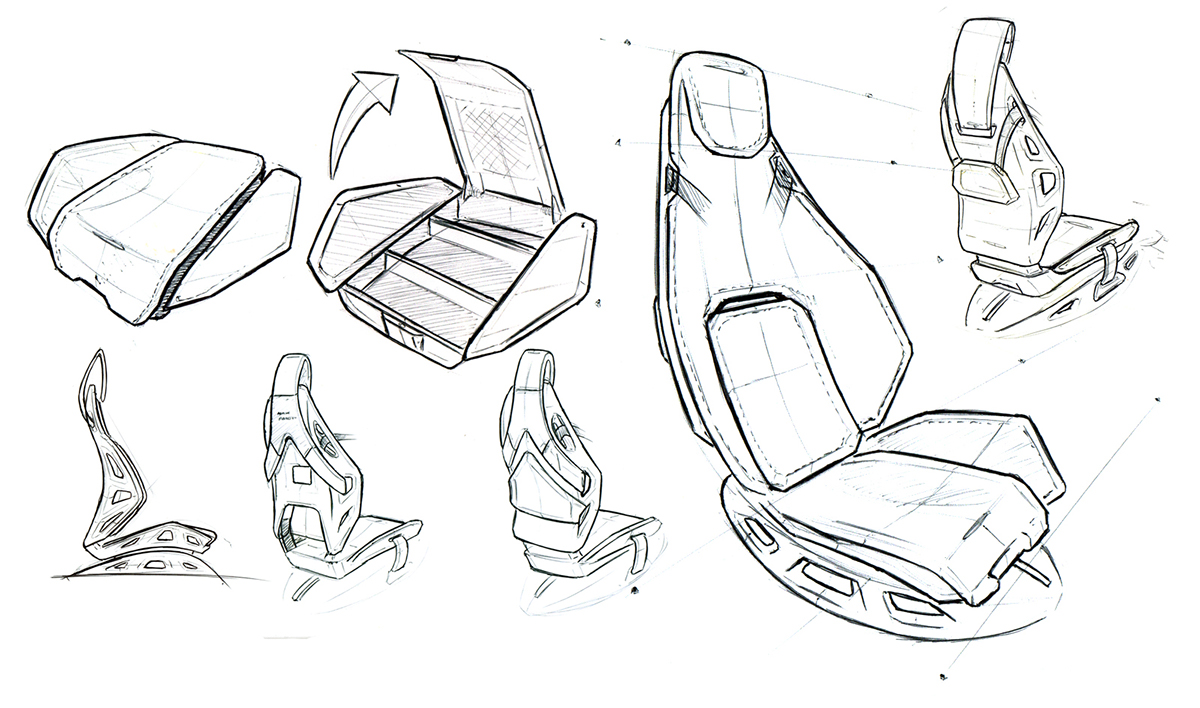

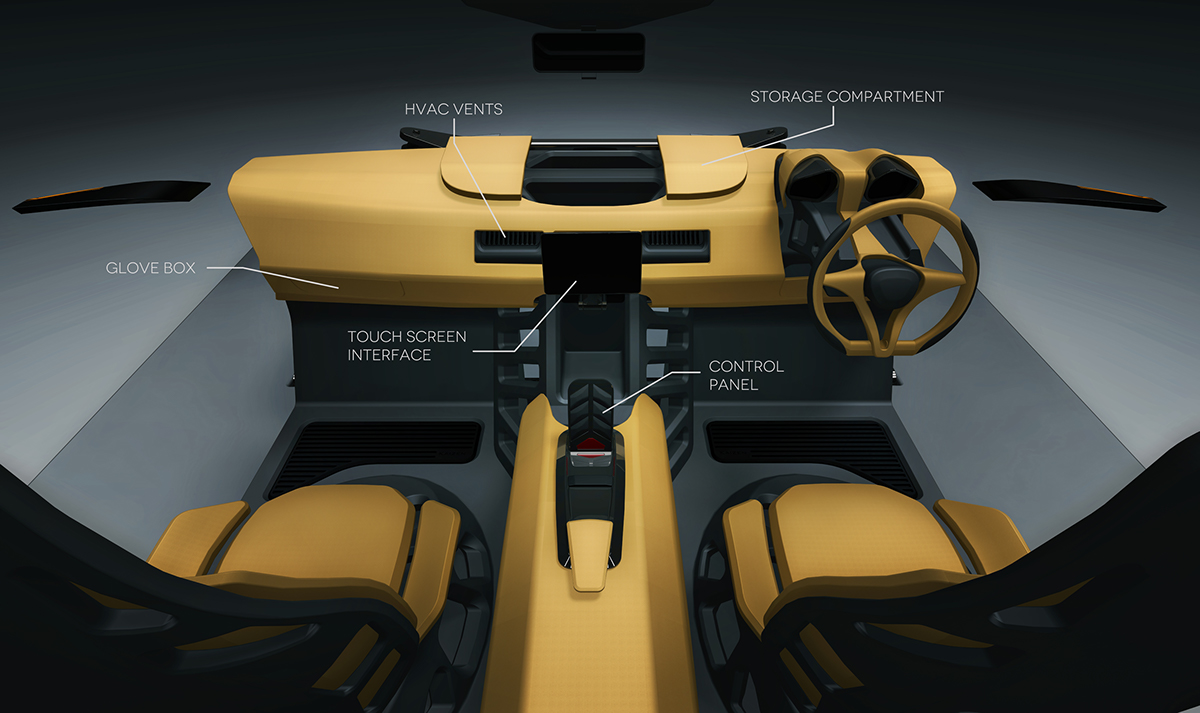

Interior Development

The interior was designed to be a visual negative of the exterior form development. Whilst the exterior focuses on aesthetic purity the interior is based mathematically ordered shapes. A complexity that both compliments and contrasts the exterior form

The interior was designed to be a visual negative of the exterior form development. Whilst the exterior focuses on aesthetic purity the interior is based mathematically ordered shapes. A complexity that both compliments and contrasts the exterior form

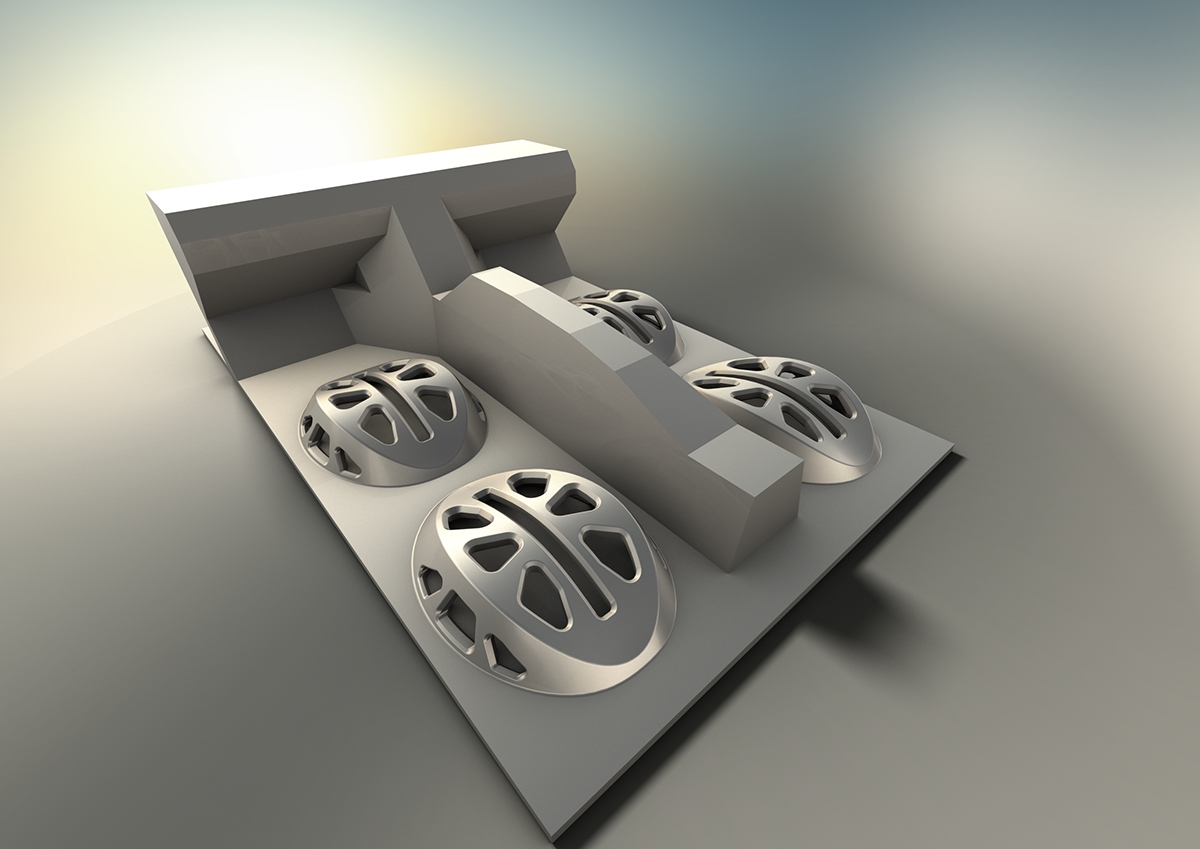

The Standardisation Approach

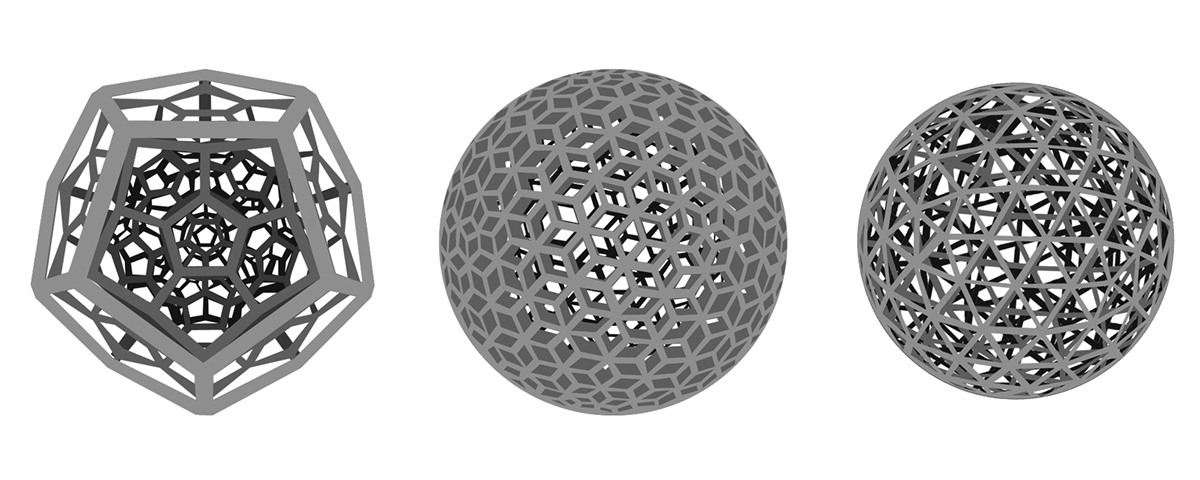

The above mathematical structure is created by tessellating a shape across a spherical body. Such shapes are almost impossible to manufacture using traditional processes, but are easily created using Rapid Manufacturing.

Not only are these shapes highly efficient in terms of strength to weight ratios, the nature of each "hole" or "shape" being the same means the object is in effect "standardised"

It is this standardisation that is carried through the interior, becoming the structure of the vehicle as well as a frame to mount all the necessary components essential to an vehicles function

The above mathematical structure is created by tessellating a shape across a spherical body. Such shapes are almost impossible to manufacture using traditional processes, but are easily created using Rapid Manufacturing.

Not only are these shapes highly efficient in terms of strength to weight ratios, the nature of each "hole" or "shape" being the same means the object is in effect "standardised"

It is this standardisation that is carried through the interior, becoming the structure of the vehicle as well as a frame to mount all the necessary components essential to an vehicles function

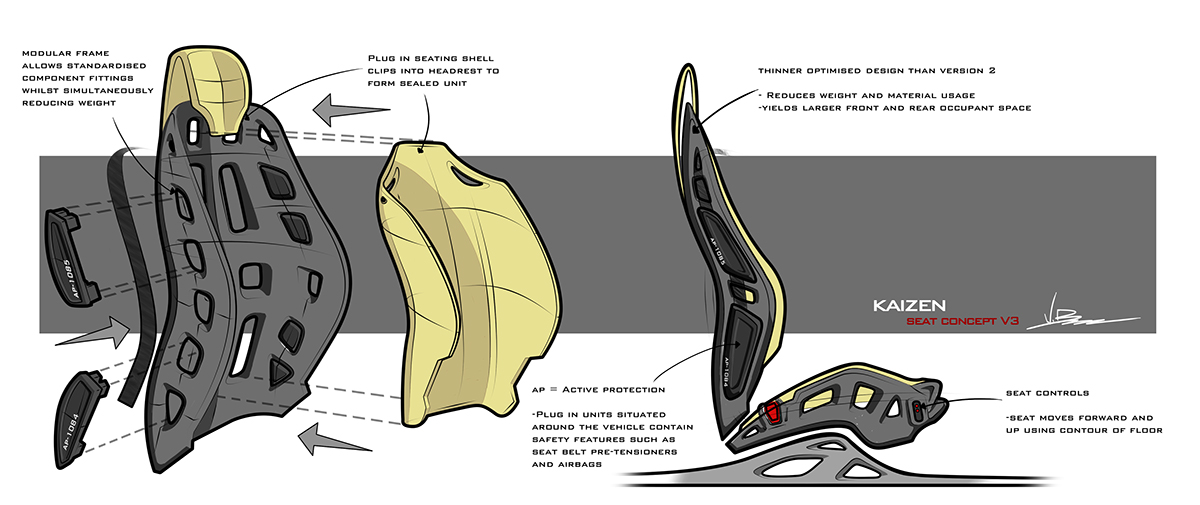

Detail Design

An in depth study into the effect of using Rapid Manufacturing on an Front Occupant Seat

An in depth study into the effect of using Rapid Manufacturing on an Front Occupant Seat

From Sketch to 3D

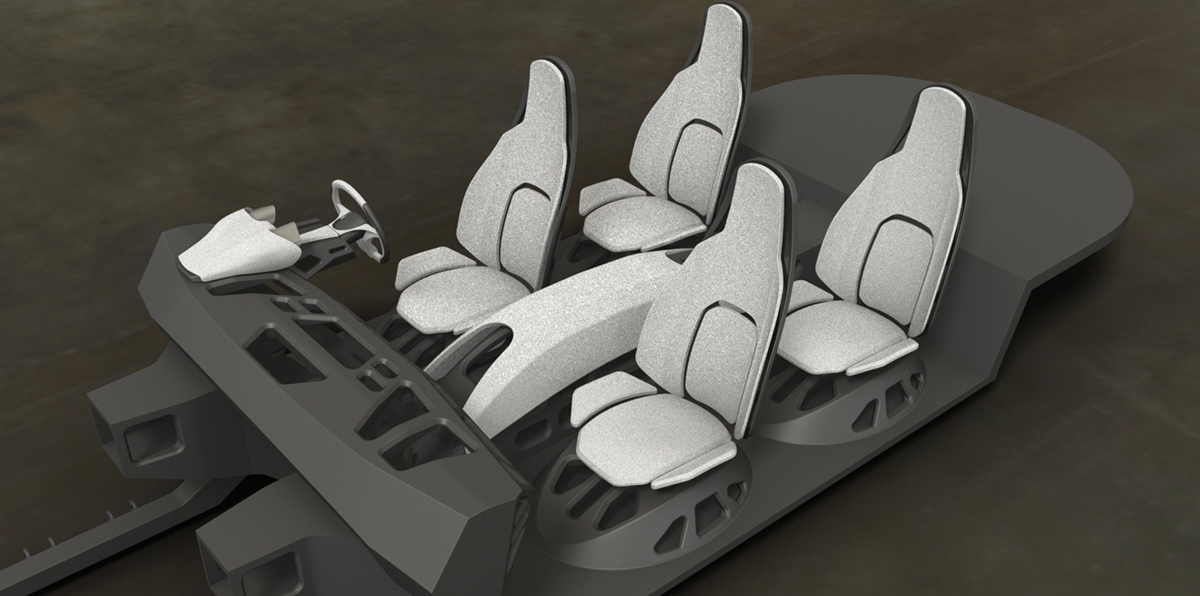

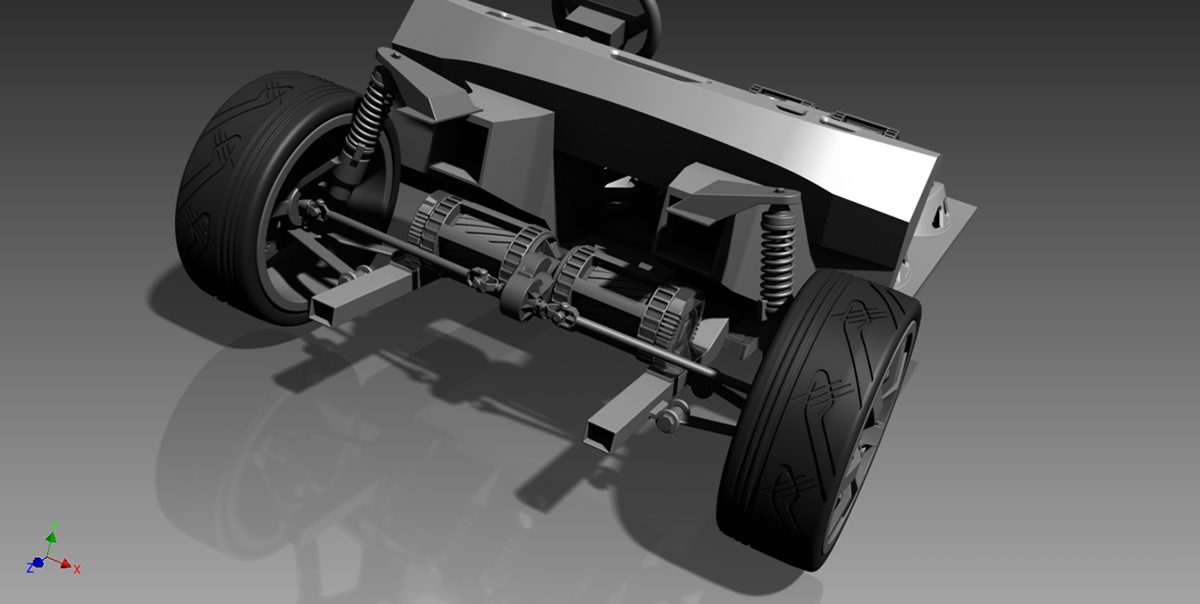

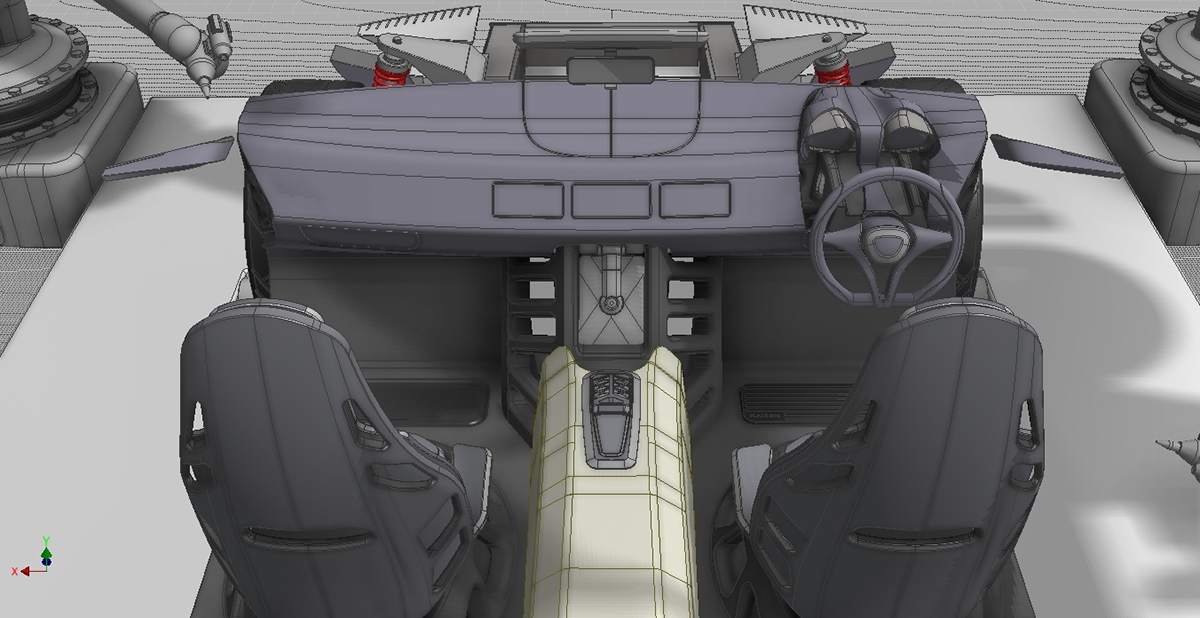

The process of translating sketch form to Final proposal began in January 2012 with the modelling of the Powertrain and the technical package. Based on various calculations on power output, aerodynamic forces, and component loadings these components were sized and modelled accordingly.

From start to finish these components were modelled in 5 weeks in Autodesk Inventor and are fully constrained. Below are the Showcase Renders used to justify the technical package to engineers.

The process of translating sketch form to Final proposal began in January 2012 with the modelling of the Powertrain and the technical package. Based on various calculations on power output, aerodynamic forces, and component loadings these components were sized and modelled accordingly.

From start to finish these components were modelled in 5 weeks in Autodesk Inventor and are fully constrained. Below are the Showcase Renders used to justify the technical package to engineers.

CAD Development

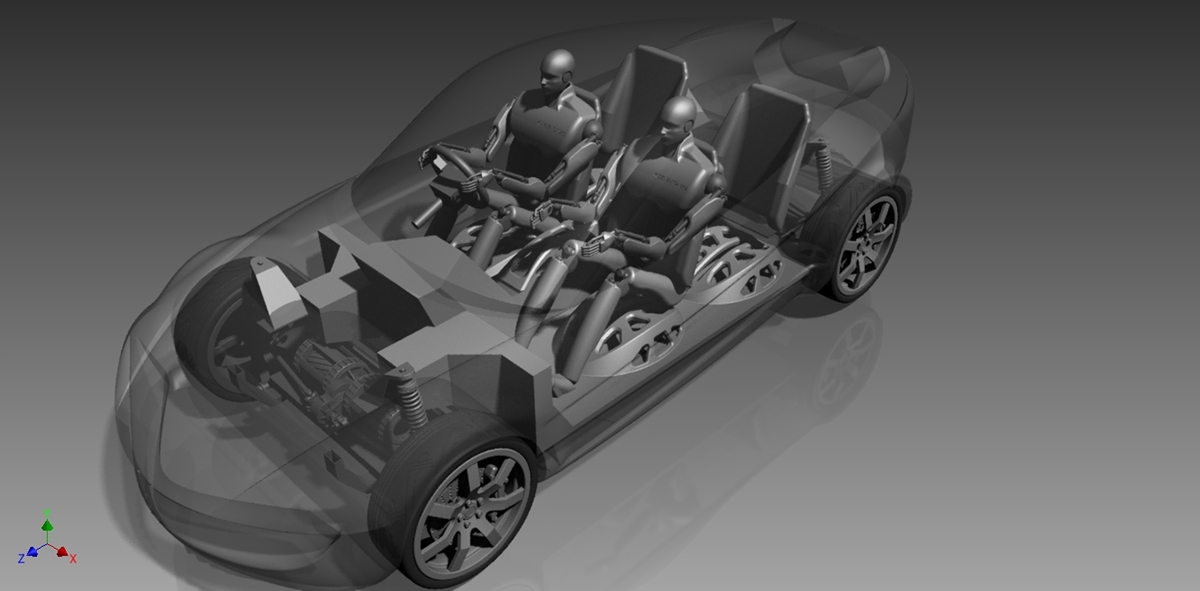

Shown Below are some of the Key Stages in Development of the CAD model. Solid Modelling was completed in Autodesk Inventor 2012 whilst the surfacing was done in Autodesk Alias 2012. The Alias Assets were then imported into Inventor to compose all the individual components together.

In total the car has over 100 unique components created in the space of 4 months brought together in a single Assembly file

Shown Below are some of the Key Stages in Development of the CAD model. Solid Modelling was completed in Autodesk Inventor 2012 whilst the surfacing was done in Autodesk Alias 2012. The Alias Assets were then imported into Inventor to compose all the individual components together.

In total the car has over 100 unique components created in the space of 4 months brought together in a single Assembly file

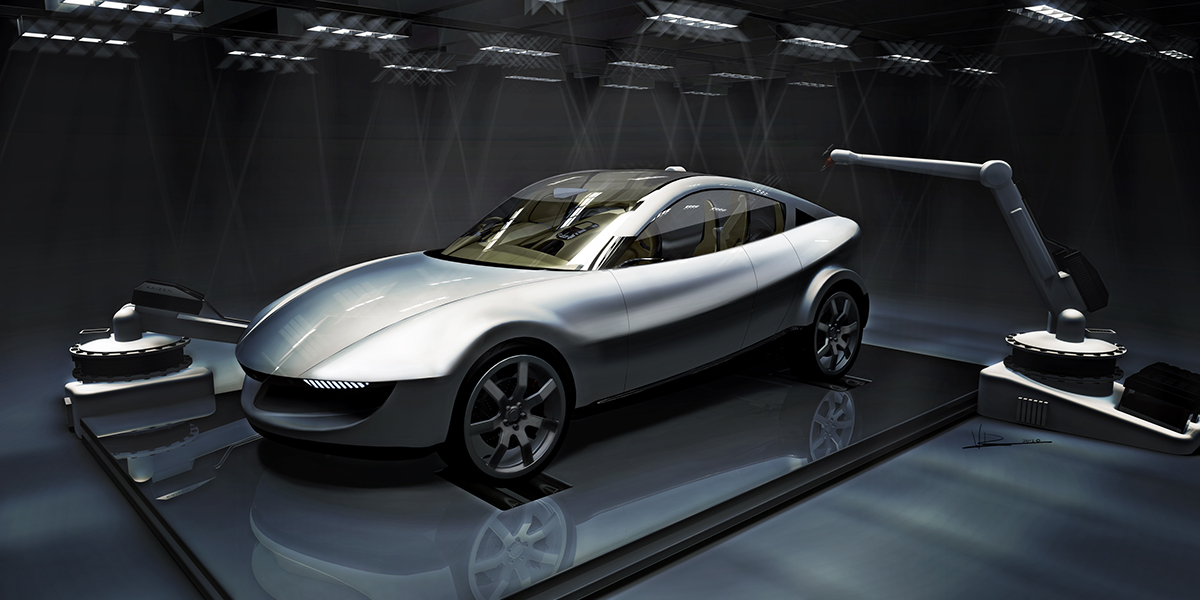

Presentation Images

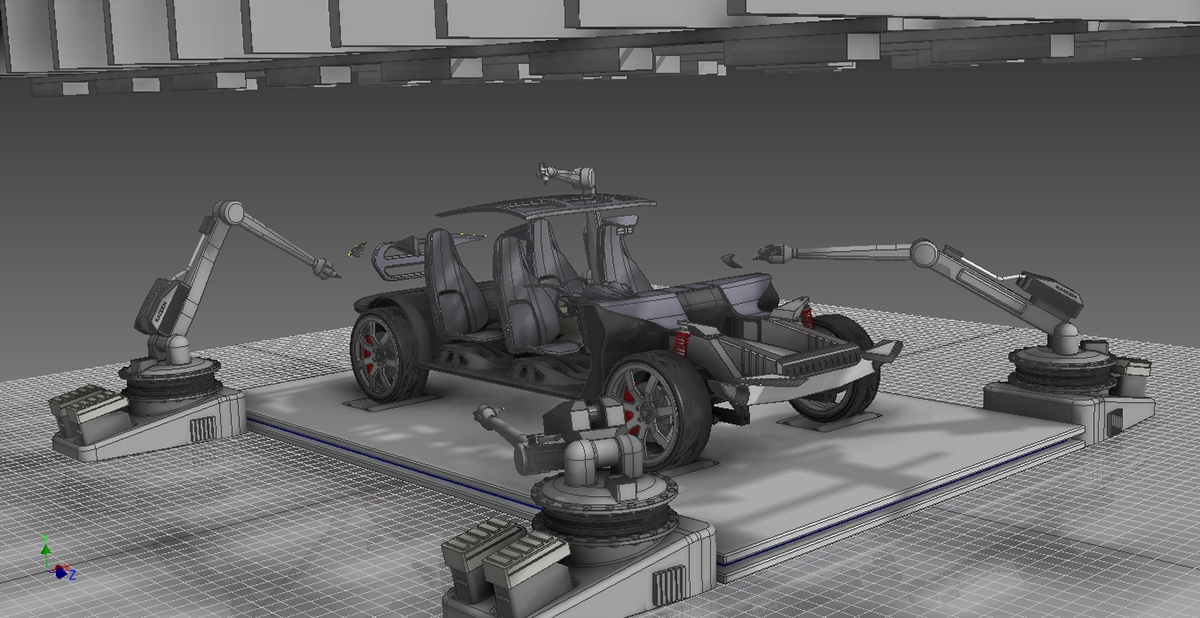

Below is the Scene file used to create the Concept Video and render the imagery for the Project. All the images were created in Autodesk Showcase 2012

These images were then subject to post production work in Photoshop CS5, this is due to Showcase having the effect of "De-saturating" some of the images. So the colours were brought closer to the original artistic vision

Below is the Scene file used to create the Concept Video and render the imagery for the Project. All the images were created in Autodesk Showcase 2012

These images were then subject to post production work in Photoshop CS5, this is due to Showcase having the effect of "De-saturating" some of the images. So the colours were brought closer to the original artistic vision

Promotional Image

As seen in the Coventry University ID Show Book 2012

As seen in the Coventry University ID Show Book 2012

Final Renders

Footnote:

Concept Kaizen was a project displayed at the Final Year Degree Show for the Automotive and Transportation Design Course at Coventry University