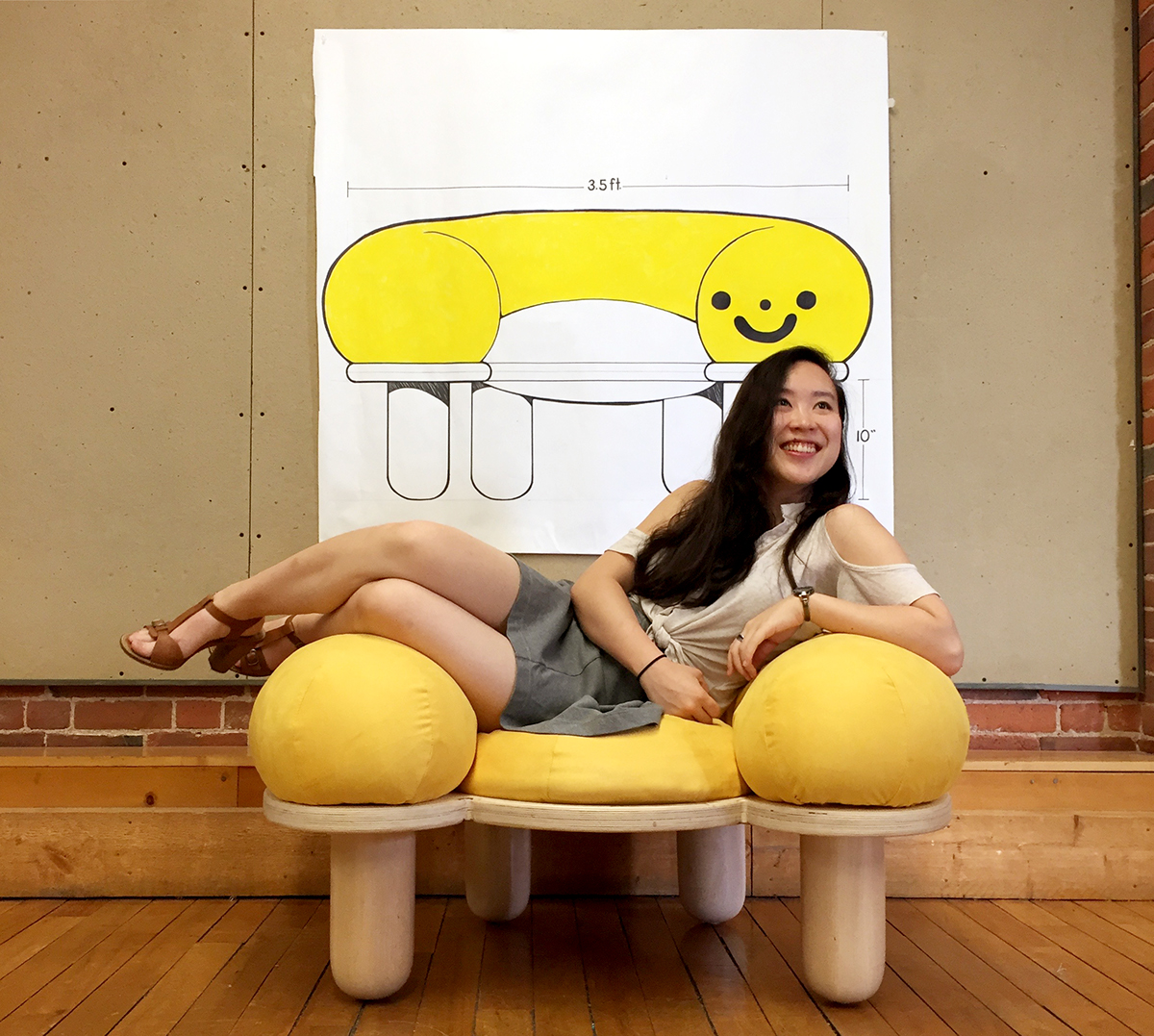

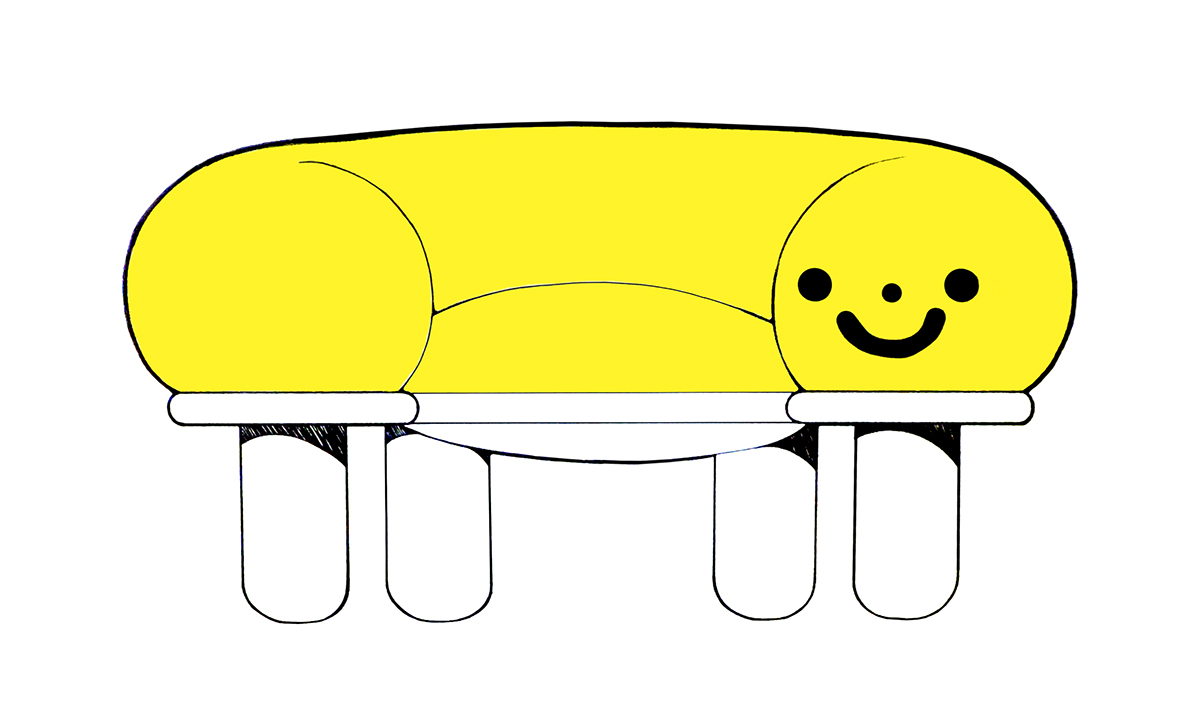

Harold is quiet but not shy. Sometimes when the weather is nice, he likes to take naps in the sunshine with his shoes off.

_________________________________________________________________________________________________

Process

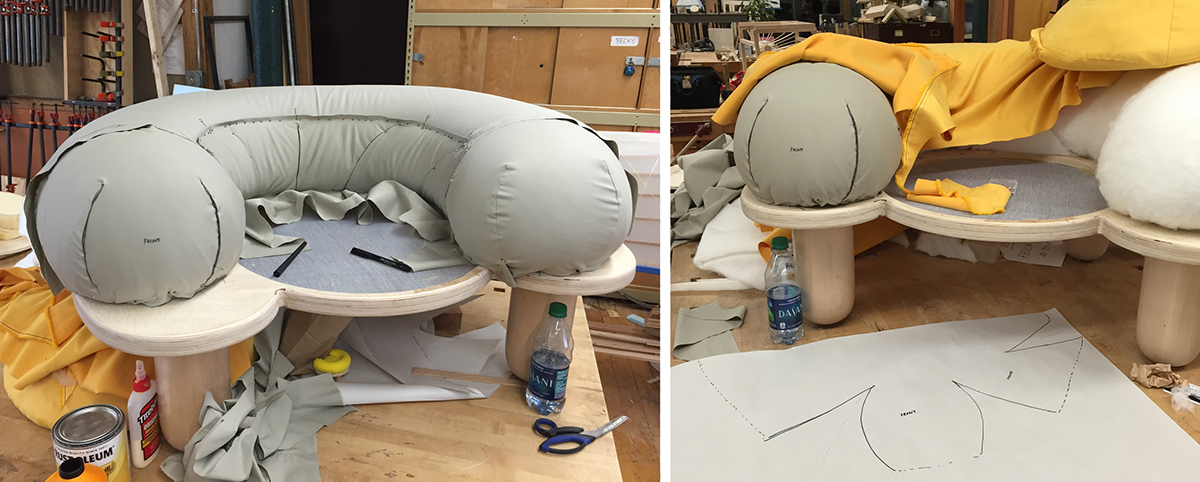

Harold's legs are 5" thick solid maple and were each turned on a lathe

The base is two layers of CNC'd plywood that sandwiches tensioned stretchy fabric. The fabric offers some give for when the cushion is sat on. The inside of the back cushion is a plywood finloft to create the desired volume.

The finloft was then filled with foam for shape and support. Each block of foam was glued in and then carved and sanded to shape.

The form was then wrapped in two layers of upholstery foam and two layers of cotton batting. The center cushion was sewn up in a partial beach ball pattern and then stuffed with upholstery foam. Egg chair!

A layer of muslin cloth was then draped and pinned in order to find the upholstery pattern. Darts were placed in specific spots in an attempt to make the pattern as clean as possible. This was my first time making a pattern or using a sewing machine so it was rather difficult.

The muslin pattern was then transferred to the final cloth which is a fake suede. The pieces were then sewn together and stapled underneath the form for tension.

_________________________________________________________________________________________________