The project involved Design for Manufacturing (DFM) analysis of the headlight mounting. The analysis was conducted based on the Boothroyd and Dewhurst DFM method and principles. Based on the results of DFM analysis, the redesign was performed to reduce the complexity of the mounting and the die. The design changes involved removing some of the external undercuts, internal undercuts, cores, shutoffs, bosses, ribs and lettering instances. The redesign resulted in a reduction of 35% in the mold cost and 38% in the mold construction cost. The detailed design changes for the headlight mounting are shown below:

Figure 1: Headlight Mounting- Isometric View

Figure 2: Headlight Mounting- All views

Figure 3: Removal of External Undercut

Figure 4: Removal of Internal Undercut

Figure 5: Removal of Shutoffs

Figure 6: Elimination of Boss

Figure 7: Elimination of Ribs

Draft Analysis

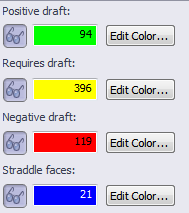

The draft analysis was performed on the redesigned headlight to understand the type of draft, draft requirements and straddle faces. The analysis showed that 94 faces had positive draft and 119 faces had negative draft. It was also understood that 396 faces required the draft. The figures indicating different drafts and analysis readings are shown below:

Draft Analysis- View 1

Draft Analysis- View 2

Draft Analysis Readings

Undercut Analysis

An undercut analysis of the part was also performed to understand different undercuts and undercut directions. The model and readings for the undercut analysis are shown below:

Undercut Analysis

Undercut Analysis- Readings