THE BRIEF: When we go to the doctor's office and they have to run some tests, that typically means the patient must wait for the doctor to send out a sample for diagnostic testing. Traditional diagnostic tests require costly equipment, attention of trained laboratory personnel, and time for material transport and process. Recent advances in the field of microfluidics and solid state fabrication can be applied to the miniaturization of medical processes to decrease time, cost, and effort required to perform standard diagnostic tests. This could help to drastically transform the way medicine is practiced.

DURATION: 05.2002 through 06.2005 (3 years)

ROLE: Research scientist and design engineer on microfluidic lab-on-chip devices

OUTCOME: integrated device successfully identifies influenza DNA sequence; results published in Lab on a Chip

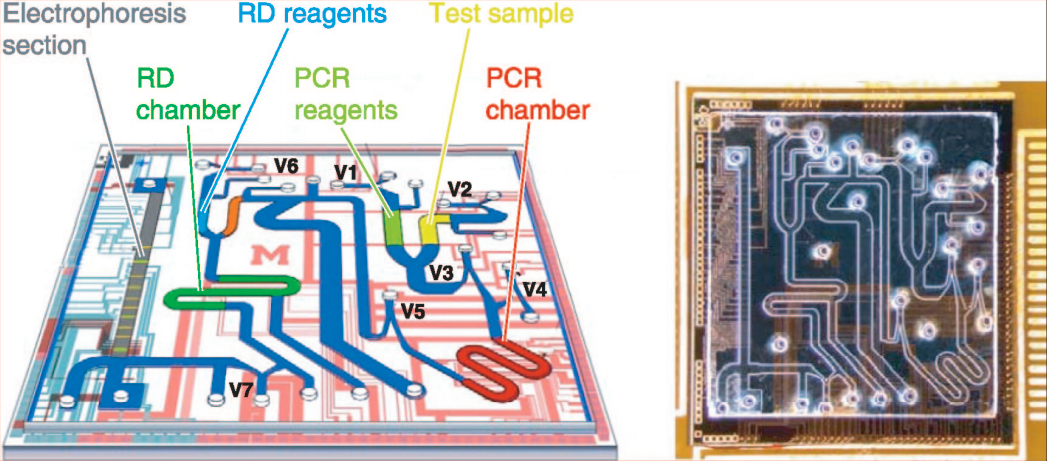

(Left) Schematic of single-reaction assay device; (Right) top-down view of glass channel layer atop silicon electronics layer

THE INSIGHT: In 1998, a team of researchers at the University of Michigan developed an integrated device with microfabricated channels, heaters, and sensors capable of performing chemical reactions at nanoliter-scale volumes. No additional external heaters or pumps were required to perform the chemical assays and analysis. The device components were fabricated using conventional solid state photolithography production techniques, allowing the components to be integrated as a single closed system.

Expanding on this platform to perform sequential reactions would allow for more complex assays to identify, for example, influenza. A miniaturized platform capable of performing complex biochemical assays like this could transform the way medicine is practiced and make this an attractive platform to be broadly disseminated in the field for diagnostic applications. My team explored designs for new integrated systems with valve-based fluidic components to enhance these microsystems and identify broader applications for the technology.

Operational states of microfluidic wax valves

THE APPROACH: In studying principles of fluidic movement at microscopic scale and the effects of heating and cooling, valves are critical to seal and protect solutions and mixtures from evaporating or mixing with other agents on the device. My team worked to develop various ideas and designs for valve applications in microfluidic devices. One such design was a Y-shaped heat-activated wax valve that could be closed by melting wax, filling the Y-valve, then cooling the wax to seal the valve. The valve could be opened by melting the wax, retracting it into the valve stem to open the channel, then cooling the wax to keep the valve open. This valve technology allowed us to create isolated and secure chambers to perform multiple chemical reactions on a single device.

I worked alongside a team of researchers and engineers to translate the theory for the component into design and fabrication processes for the solid state hardware. I designed and tested various component designs using standard photolithographic fabrication processes, assembling component prototypes, and iterating on the design to determine which would perform most effectively as part of the integrated system.

(Left) Design schematic of valved multi-reaction device; (Right) top-down view of etched glass channel layer atop silicon electronics layer bonded to PCB

Upon completing the validation of a valve component, my team designed a multi-reaction device based on the valve technology described above to perform a sequential reaction assay for the identifcation of a specific strain of influenza. As described in the illustration below, the device first performs an amplification reaction to increase the concentration of DNA in the test sample via a polymerase chain reaction (PCR) assay. This ensures that the sample in concentrated to a level that is detectable by the sensors on the device. After this initial step, the amplified DNA (called the PCR product) is advanced to a restriction digestion (RD) reaction which breaks the DNA down to smaller sequences to detect whether or not sequences specific to influenza are present. This is analyzed in the final process on the device where the digested sample is run on a microscopic electrophoretic gel which separates the DNA fragments by size. The pattern that results can be used to determine the DNA composition of the sample and identify the presence of influenza.

I managed the end-to-end delivery on this project including device design, fabrication, assembly and testing. After multiple iterations and refinements, we were able to successfully process and identify influenza affected DNA against uninfected control samples.

Illustration of fluid flow through the valved multi-reaction device to perform a PCR + RD assay followed with analysis by gel electrophoresis