This began as a minor studio project. This project is targeted towards the competitive snowshoe racer. There currently is no high end competitive offering of snowshoes that boast a carbon fiber frame. Using the same manufacturing process as tennis rackets (inflation bladder molding), an extremely light and strong product can be made. Won Gold in the European Product Design Awards.

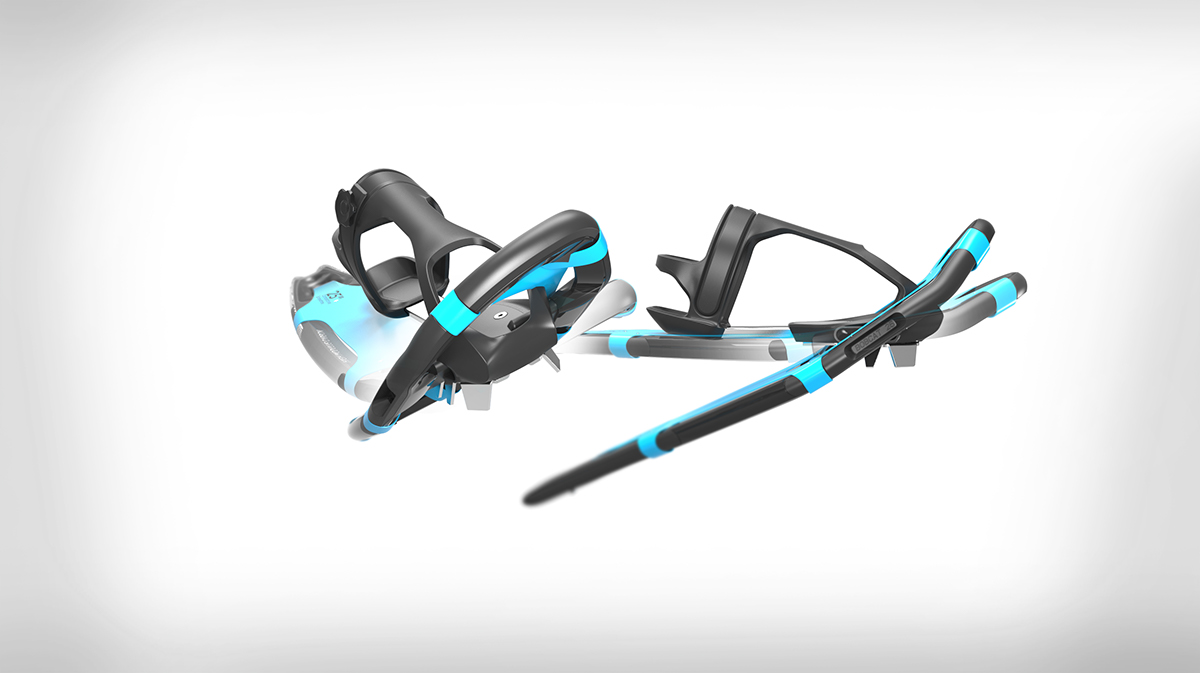

Money Shot

During rapid sprinting it is hard to fully control the shoe. Often it will interfere with the opposing leg, which can led to mild irritation, tripping or even the possibility to injure one self.

This is a quick mock-up of an asymmetrical design to provide better clearance while runner. This shape allowed for a more care-free sprint and more natural movements.

Splash page

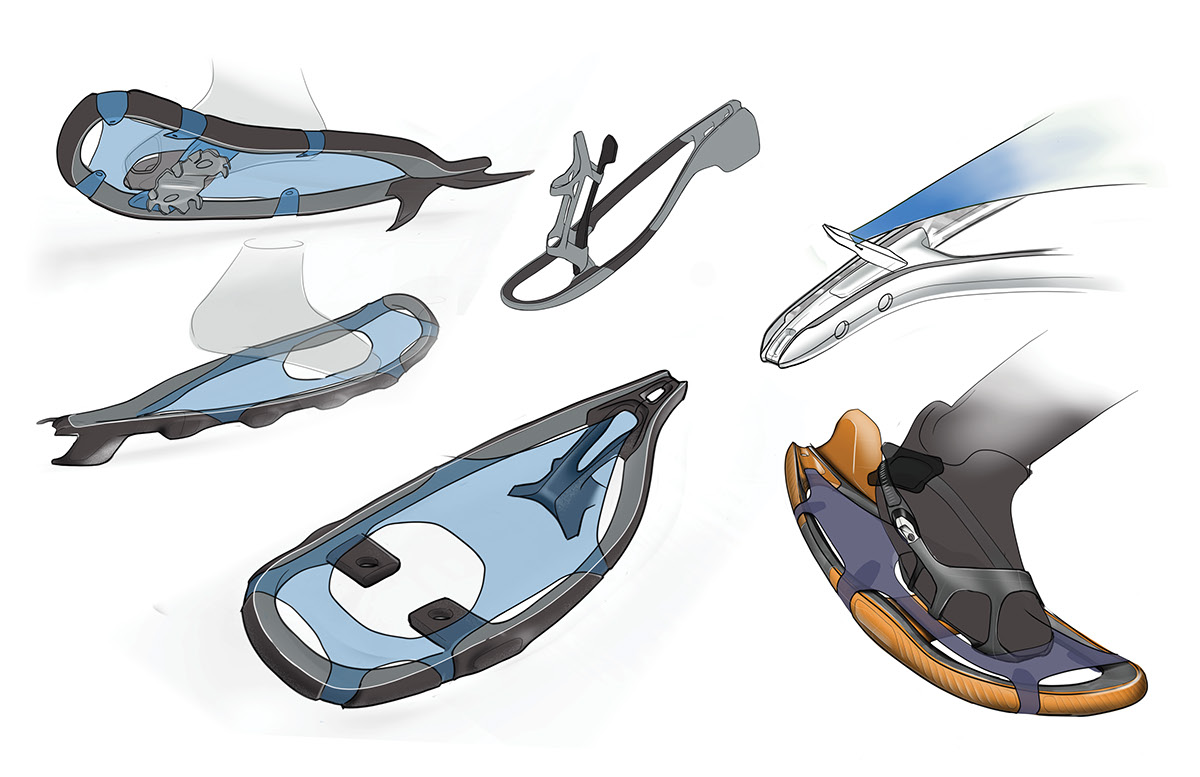

Sketching Lineage and influential imagery.

Physical to digital process. 1. I first built an armature from the final intent sketch. 2. I then used automotive clay to sculpt over the 3D printed armature. 3. Once happy with the clay model I had it digitally scanned and re-meshed for CAD handling. 4. From the scanned data I could then build my CAD surface model. 5. Finally, I 3D printed and finished my snow shoe frame.

3D printed model

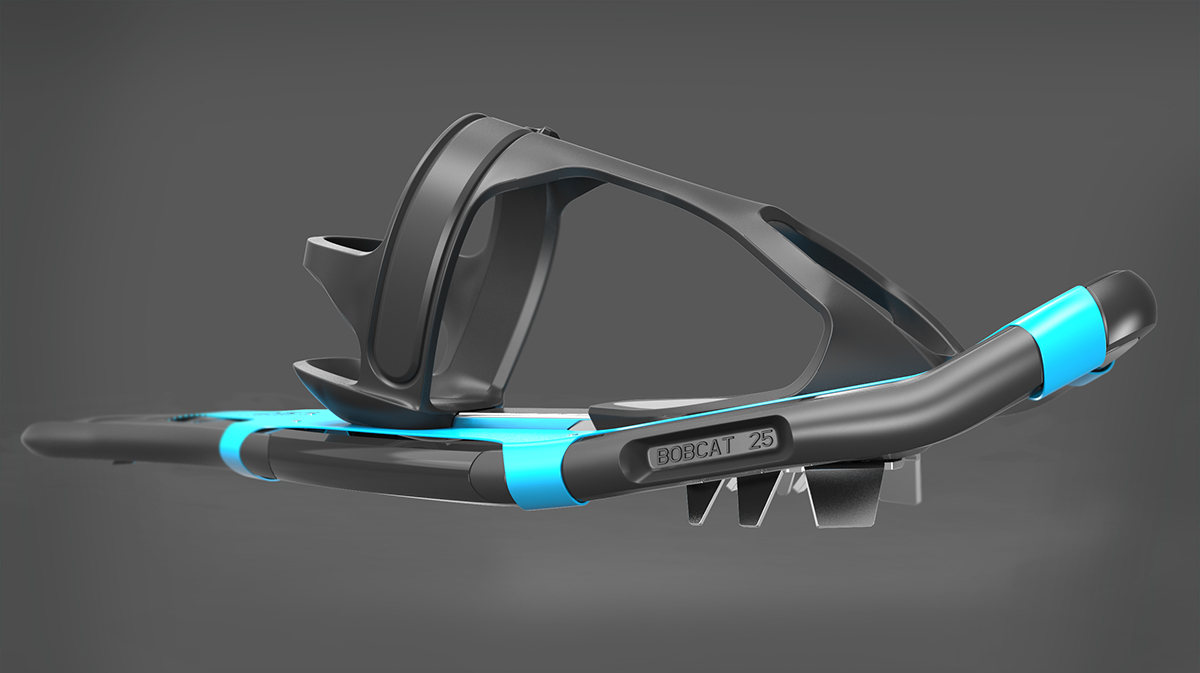

Top

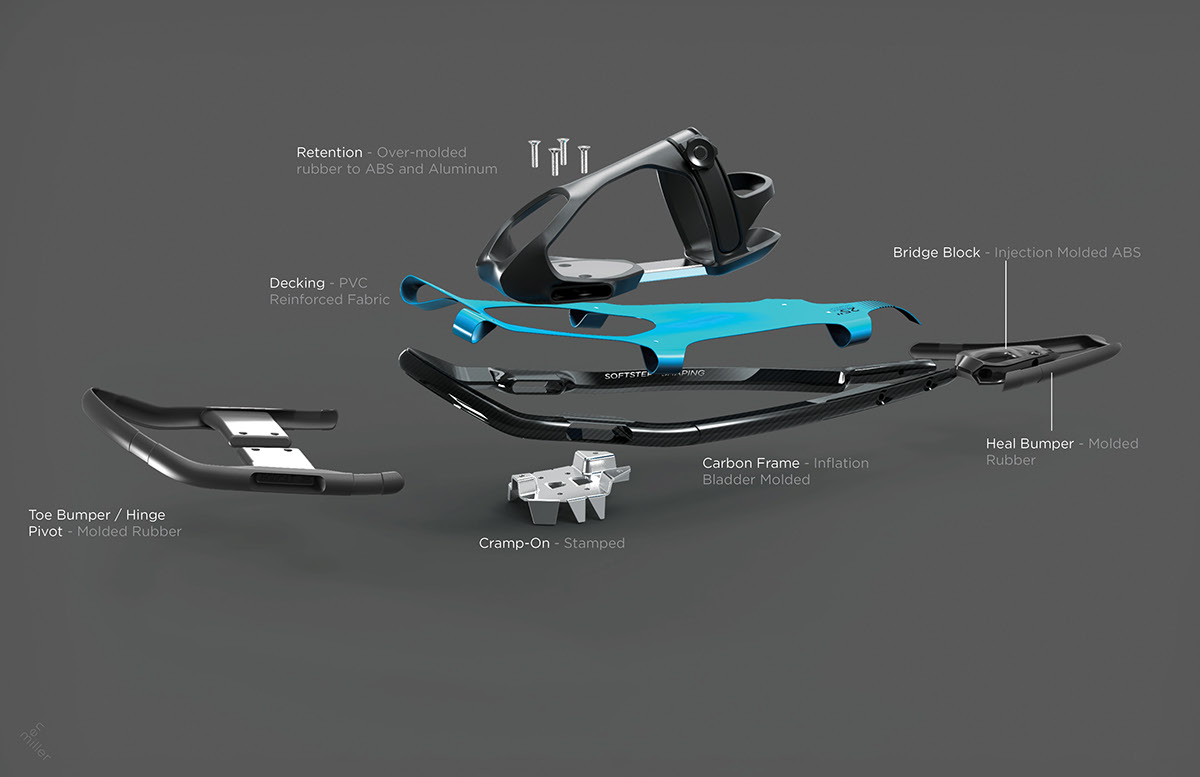

Exploded

Side

Motion

On figure