Preparation of a fiberglass mold

and extraction of copies.

STAGE 1 - Polish and brightening of the master piece.

We have obtained the master piece through the Stereolithography (SLA) technology, then we carried out a process of filing, polished and brightening of the piece to get a good finish of the fiberglass mold, due to the finishing of the mold will determine the finishing of the extracted copies.

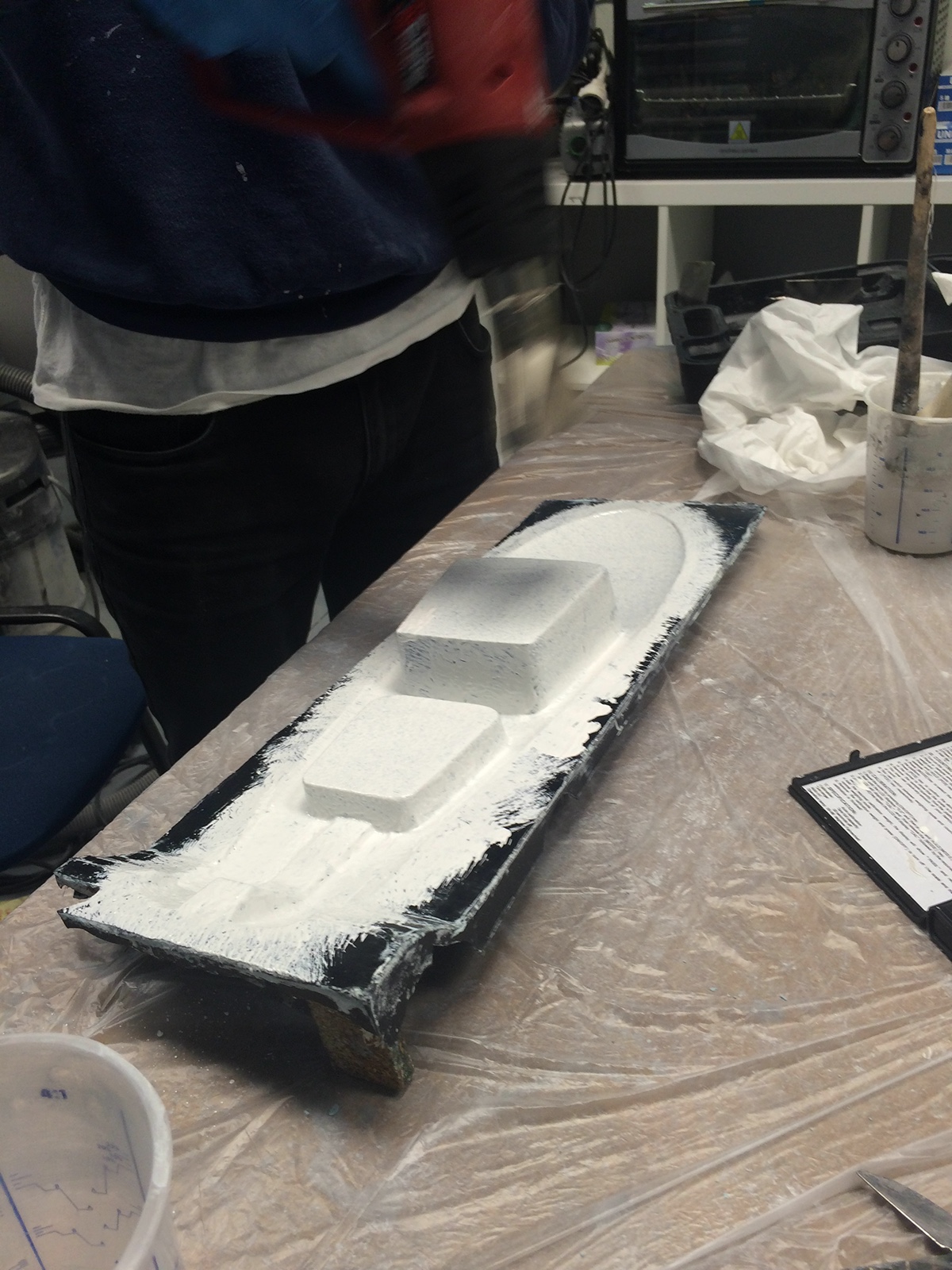

STAGE 2 - Laminate of the fiberglass mold and extraction of the master piece from the mold.

The master piece is placed in a wooden structure, created by ourselves, to define the partatge line of the mold, then three layers of gel coat black are applied, also resin is applied and, finally, the tissue of fiberglass is deposited. From here, we apply 6 or 7 layers of fiberglass with resin to give maximum resistance to the mold.

Finally the wooden boxes is removed and the master piece is remove from the mold to get fiberglass mold where the copies will be extracted.

STAGE 3 - Creation of copies.

Once the mold is created and the master piece is removed from the mold, first, it is necessary to apply 6 layers of wax into the mold as a mold release for future copies of the master piece. Then, we shall apply 3 layers of white Top Coat, 2 layers of resin to hook the fiberglass tissue and, finally, between 3 or 4 layers of fiberglass to give consistency to the copies.

Once the mold is created and the master piece is removed from the mold, first, it is necessary to apply 6 layers of wax into the mold as a mold release for future copies of the master piece. Then, we shall apply 3 layers of white Top Coat, 2 layers of resin to hook the fiberglass tissue and, finally, between 3 or 4 layers of fiberglass to give consistency to the copies.

STAGE 4 - Extraction and finishing of the copies.

Finally, once the copy is made, the mold is separated from the copy and the possible imperfections of the mold are repared (scratches, holes, burrs, etc..). In Conclusion, The first stage of the process is repeated but using the final piece.

THANKS FOR WATCHING ! ! ! !