Mars Habitat

Modular living units for Mars colony

Northrop Grumman Corporation, 2005

Redondo Beach, California — One of the first large-scale projects I was able to participate on was joining a multi-sector team tasked with developing early concepts for a Mars habitat to support Northrop Grumman's Crew Exploration Vehicle Orion (CEV) proposal. I was able to work closely with engineers and other industrial designers and the renderings below demonstrate the solution we came up with. The rendered models below were created by Northrop Grumman's IMAGE Center based off of the research and sketches I produced.

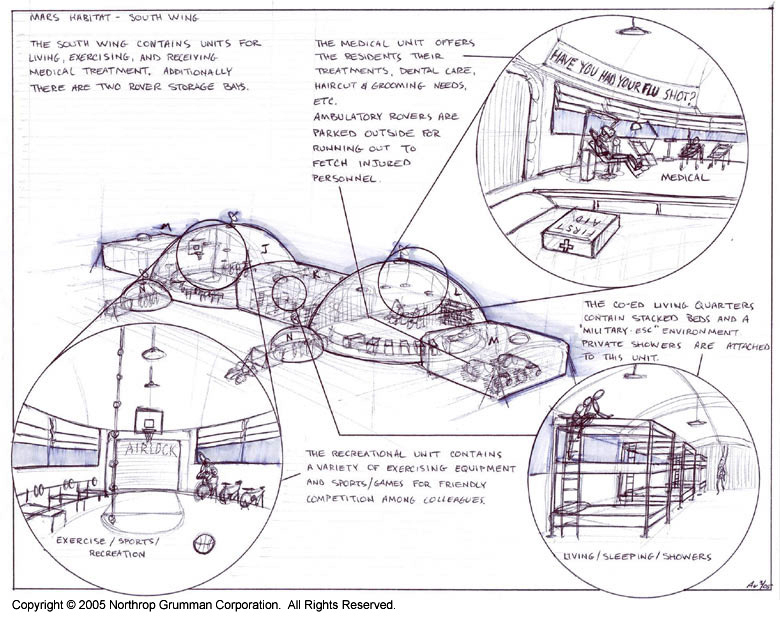

The flexibility of the pods and connection adapters allow for easy growth of the colony as additional missions land. Courtyards are also formed throughout to protect supplies and shield materials from the constant dust storms and vicious winds.

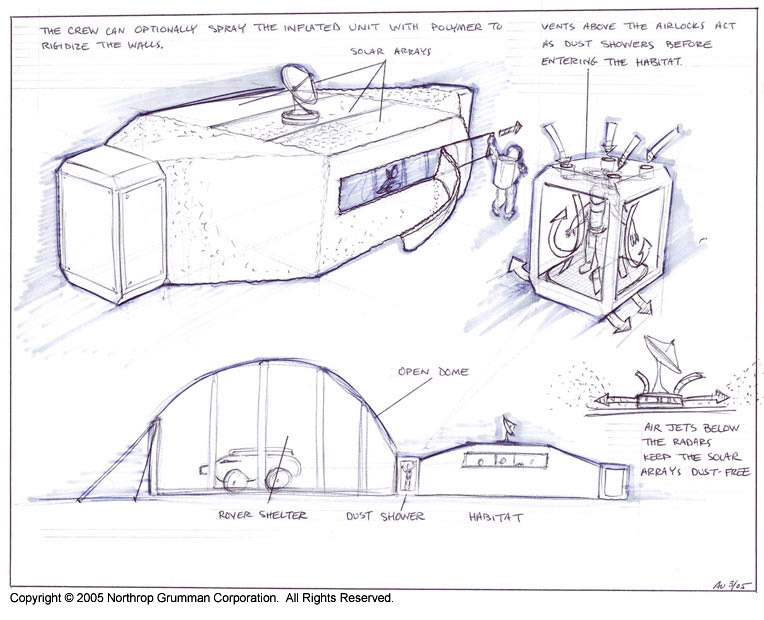

A remote maintenance robot (not pictured) performs simple tasks such as cleaning security cameras and solar arrays, as well as transporting materials long-distances across pods via the roof-track. This allows the crew to remain indoors while performing tasks on the outside of the structure.

Screened-in porches and dust vacuum entrance ways provide the crew a moderately protected room to dust off and unload materials before entering the structure.

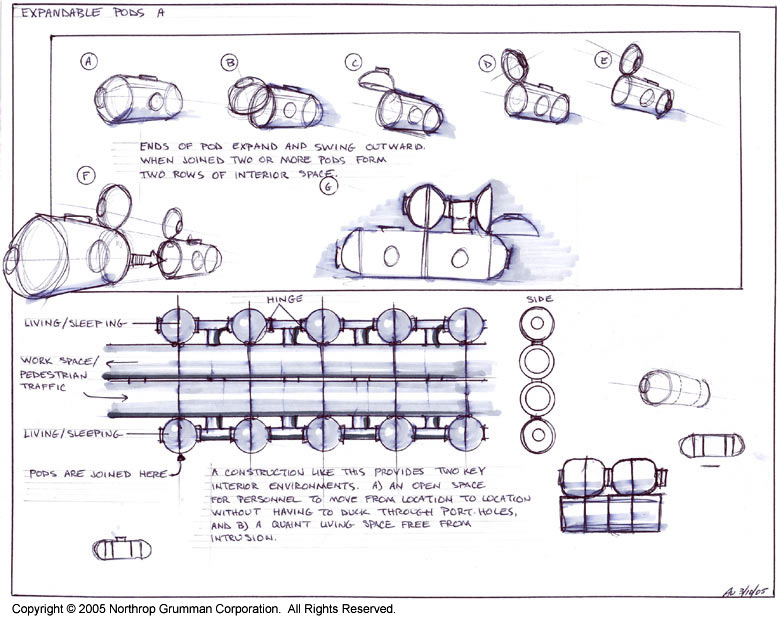

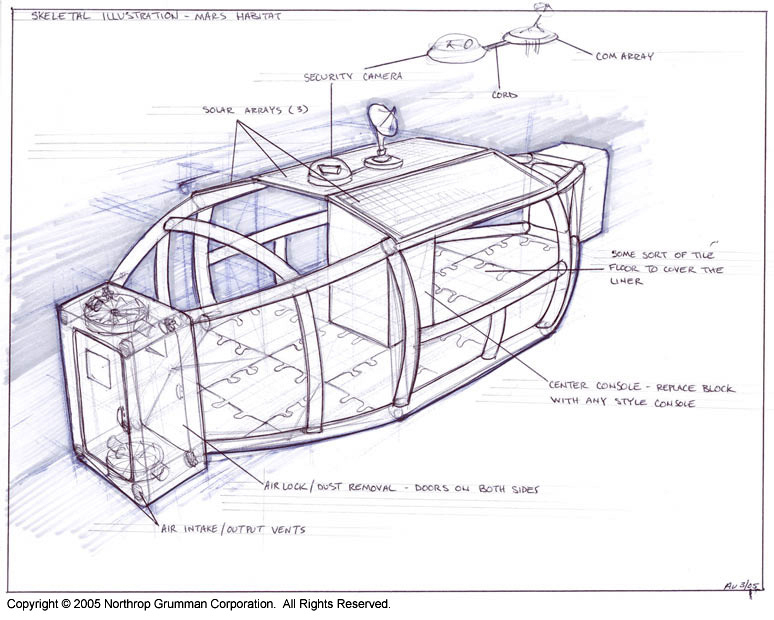

One of the challenges of this project was that the entire structure needed to fit on the back of a flatbed truck and fit within the cargo bay of our proposed spacecraft. The concept above was one of many considered at the beginning of the proposal - a capsule that could open on both ends and connect itself to form long living and working corridors.

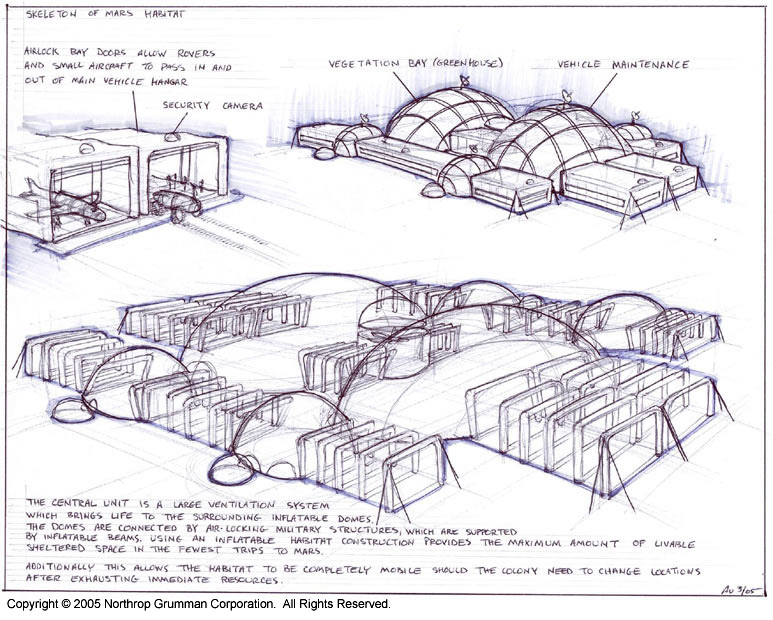

We explored possibilities with some of the military's inflatable structures to maximize real-estate per mission.

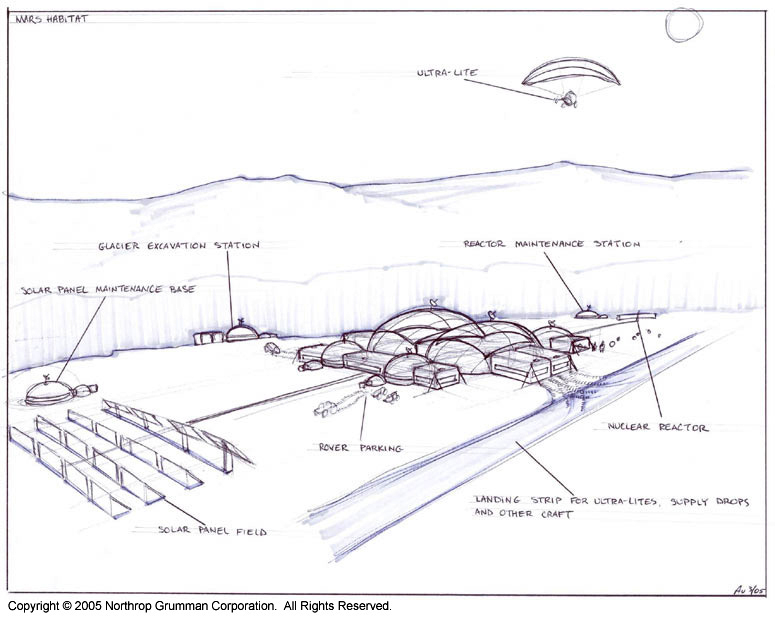

Early layout of the base camp meeting all of the proposed camp requirements.

The final design ended up as a rover-deployed hexagonal structure that would be dropped to the planet's surface separate from the crew landing. Using either manned or remote rovers, the crew would properly orient the structure and its parts.

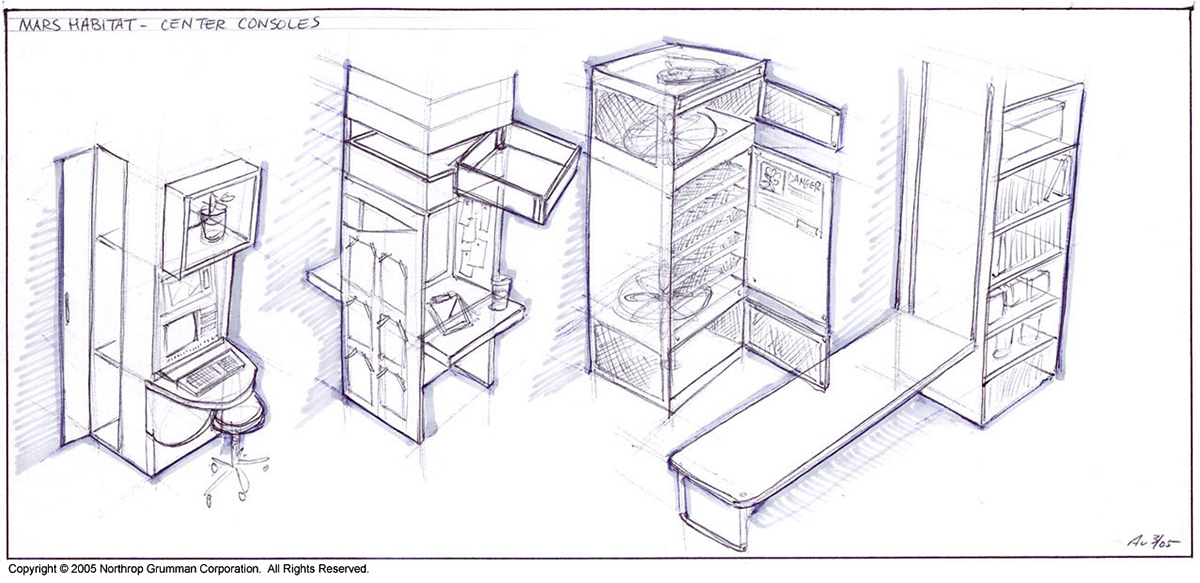

The center pillar of each module was customizable to meet the needs of its location within the camp. Some modules served as ventilation, some functioned as offices, others as living space.

Depending on cargo space and environmental needs, a polymer spray would stiffen the walls of the structure and add more protection and shelf-life to the camp.

Images Furnished Courtesy of Northrop Grumman Corporation.

Rails were added to structure late in the proposal to accommodate a maintenance robot that could perform simple tasks like cleaning the solar arrays and security cameras. This would allow the crew to remain indoors without having to suit up to perform routine tasks around the camp.