Most shoe packaging involves immense wastage of cardboard boxes, which are usually not recycled. We as a group of six designers have worked on the recycling element by using MDF i.e. Medium Density Fireboard as our material, which is an engineered wood product made by breaking down hard and soft wood residue into wood fibers.

We studied the industrial process and how to make our product packaging friendly for the company, based on which we decided on the target customers. From logo design to creating an instruction manual, we also worked on different perspective when it comes to launching a brand and by taking into consideration the factory as well customers involved in this whole industrial process.

We have also targeted many aspects like manufacturing, packaging, distributing etc., but one of the major aspects of shoeboxes, which we covered, was the post-packaging process. Our target audience was 18-25 years of age, mostly college students. This age group is considered to be usually on the go and with changing hostels; apartments etc. who require cheap and compact storage spaces.

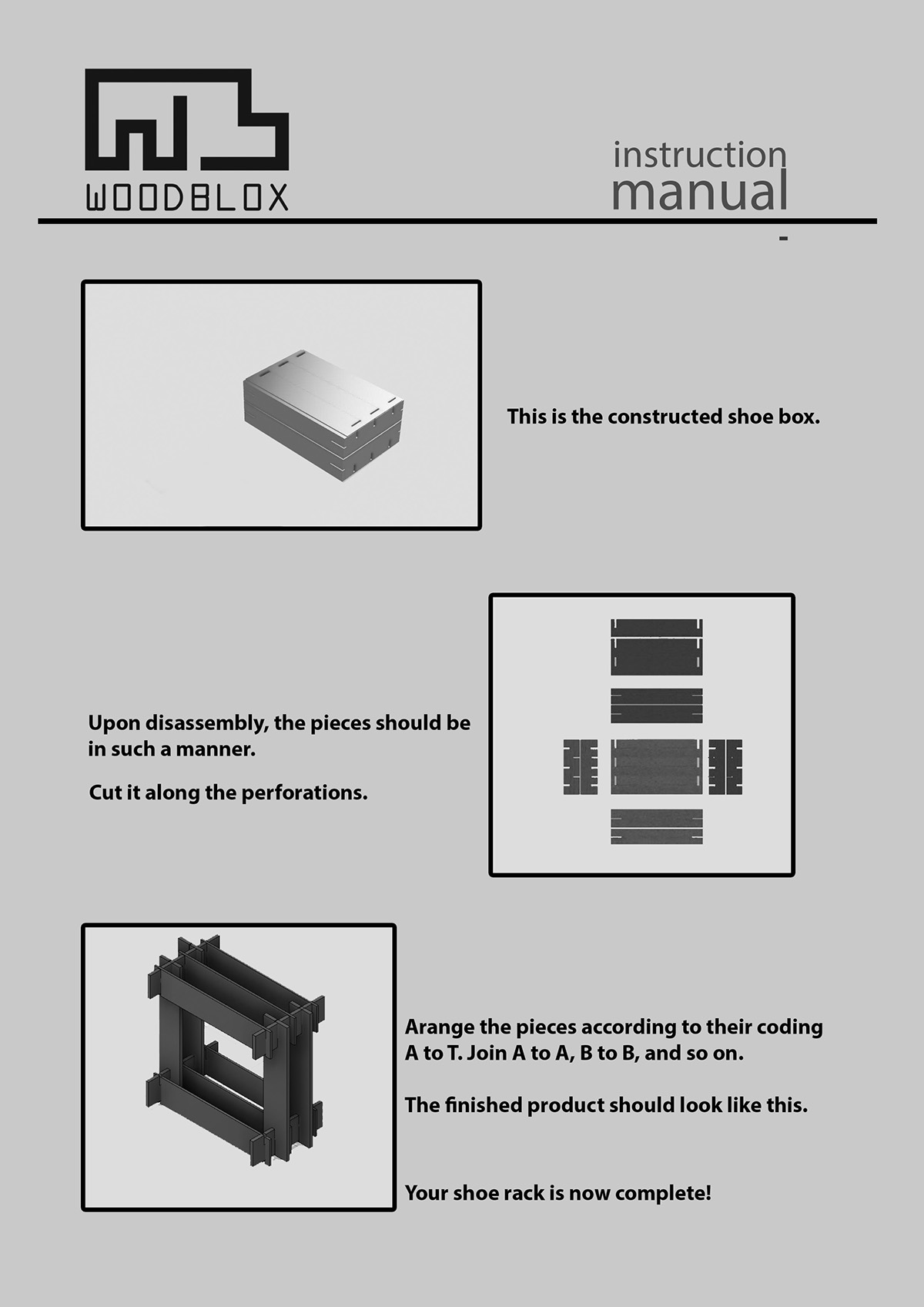

So, our design of the shoebox is such that it can be dismantled from the provided perforations on the box done by Laser cutting and with the help of the instruction manual can be arranged into a Shoe Rack, which would be compact, durable and can be easily carried.

The process of making the Shoe Rack

The Instruction Manual

Working as a group we suggested and bounced concepts and ideas off each other. This helped us look into each idea individually, learn from them and develop them further. We took the idea, which we thought had a wider scope to work with and would be commercially essential. We also gained a lot from the feedback received from our peers, which helped us in the overall product development.

The team:

Shreyansh Baid | Shreyansh Gupta | Nishant Gantha | Sushmita Hatte | Rhea Gupta | Manu Sharma