Products from the collection at the brand launch event. Image from Target Corporate site.

All products in the 16' run.

The context

Target's school and office department was looking to reinvent the product in the former scrapbooking and memory keeping aisle - who knew preserving physical photos via scrapbooking was going out of style? The solution was a new line of DIY art and crafting product focused on the millennial ‘maker’ guest - think Michael’s - designed by Todd Oldham. The Hand Made Modern (HMM) product brand was born.

The challenge

Sounds great... now what? The decision to develop entirely new product was made very late in the game, which made the way we got the work done one of the most unique challenges. Corporate product development timelines in my experience are work-back schedules from when the product must be set on the store shelf - at Target, standard development kicks off around 45 weeks out. With HMM, we kicked off at 30 weeks out. Knowing that distribution, production and execution are non-negotiables, the team identified steps that could evolve, shorten or go away to lean out our clunky development process. One of those areas was structural packaging engineering and design: I typically get 20 weeks to concept, engineer, refine and finalize structural packaging for a program, but with HMM it was 7.

The work + my role

Typical product development looks like a relay race, but for this program, we basically broke the baton in pieces and ran in parallel to the finish. My role, to quickly and efficiently develop new structural packaging designs, was happening in tandem with new product development, new brand development, new merchandising strategy and onboarding and selection of new product manufacturing vendors.

Target's school and office department was looking to reinvent the product in the former scrapbooking and memory keeping aisle - who knew preserving physical photos via scrapbooking was going out of style? The solution was a new line of DIY art and crafting product focused on the millennial ‘maker’ guest - think Michael’s - designed by Todd Oldham. The Hand Made Modern (HMM) product brand was born.

The challenge

Sounds great... now what? The decision to develop entirely new product was made very late in the game, which made the way we got the work done one of the most unique challenges. Corporate product development timelines in my experience are work-back schedules from when the product must be set on the store shelf - at Target, standard development kicks off around 45 weeks out. With HMM, we kicked off at 30 weeks out. Knowing that distribution, production and execution are non-negotiables, the team identified steps that could evolve, shorten or go away to lean out our clunky development process. One of those areas was structural packaging engineering and design: I typically get 20 weeks to concept, engineer, refine and finalize structural packaging for a program, but with HMM it was 7.

The work + my role

Typical product development looks like a relay race, but for this program, we basically broke the baton in pieces and ran in parallel to the finish. My role, to quickly and efficiently develop new structural packaging designs, was happening in tandem with new product development, new brand development, new merchandising strategy and onboarding and selection of new product manufacturing vendors.

So the odds were kind of stacked against us, but how did the team prevail?

1) Leadership support. We basically left our day jobs supporting other brands and businesses to get this thing done. True testiment that the tiger team approach allows you to full immerse and be your most efficient and focused self.

2) Embracing the ambiguity. This group was able to find comfort in the unknown and really questioned what pieces of information were required to make decision vs. what info is nice to have. Also, just having empathy for one another and respecting the fact that our peers may not have all the answers that they usually do.

3) Passionate teammates. The level of committment to the project was unmatched.

There were some really great structural packaging wins developed along the way, highlighted below.

There were some really great structural packaging wins developed along the way, highlighted below.

Inspirational hangtag, ribbon rolls + glitter library (respectively).

Inspirational hangtag

The product assortment guides consumers to purchase a base, then empower them to decorate and stylize the base with embellishments and paints. Creating a hangtag that inspires was critical to breaking down the intimidation factor and instilling confidence in the consumer. Goal was to use photos and witty copy to make the mental bridge between between blank canvas and finished craft project. My role was to design a structure that provided room for ample photography, but maintained brand consistency across a visually busy assortment.

The final design was a folding hangtag that showcased a clean brand aesthetic, but when opened, provided 2 panels of space for photo and copy. I also implemented a dyed cotton string to match the color-coding per product category - a green to indicidate "base" products and blue for "embellishments".

The product assortment guides consumers to purchase a base, then empower them to decorate and stylize the base with embellishments and paints. Creating a hangtag that inspires was critical to breaking down the intimidation factor and instilling confidence in the consumer. Goal was to use photos and witty copy to make the mental bridge between between blank canvas and finished craft project. My role was to design a structure that provided room for ample photography, but maintained brand consistency across a visually busy assortment.

The final design was a folding hangtag that showcased a clean brand aesthetic, but when opened, provided 2 panels of space for photo and copy. I also implemented a dyed cotton string to match the color-coding per product category - a green to indicidate "base" products and blue for "embellishments".

Ribbon rolls

Key insight guiding structural design for this item was that ribbon was not a one-and-done item and we wondered how packaging might be able to dispense and store the product. In partnership with Todd's design studio, we engineered a carton that doubled as a dispenser through the slot on the right panel. Rotating the peg hole 45 degrees to hang angled rather than straight also added visual interest. This is a great example of acting quickly on an insight, but there's still appetite to continue to rework and refine this solution.

Key insight guiding structural design for this item was that ribbon was not a one-and-done item and we wondered how packaging might be able to dispense and store the product. In partnership with Todd's design studio, we engineered a carton that doubled as a dispenser through the slot on the right panel. Rotating the peg hole 45 degrees to hang angled rather than straight also added visual interest. This is a great example of acting quickly on an insight, but there's still appetite to continue to rework and refine this solution.

Update: this packaging design actually got some great organic feedback on social media, shown above!

Zoom in on the back panel of the glitter library showing the caddy functionality, in fully printed packaging.

Glitter library back panel photography

I am particularly proud of the glitter library packaging, as it represents another moment the team took a step back, asked why, and was able to bend rules to deliver something awesome.

A simplified workflow to the way we develop packaging is that we 1) create the structure, 2) design a graphic layout template, 3) fill that template with copy and photography from the phoot shoot, then 4) ship the file to be printed + manufactured produced.

I am particularly proud of the glitter library packaging, as it represents another moment the team took a step back, asked why, and was able to bend rules to deliver something awesome.

A simplified workflow to the way we develop packaging is that we 1) create the structure, 2) design a graphic layout template, 3) fill that template with copy and photography from the phoot shoot, then 4) ship the file to be printed + manufactured produced.

In this instance, I had designed a caddy feature into the package, which was cool, but the team was not sure the consumer would know it's there. A visual was needed to explain the function. We've never shown packaging in on-pack photography because we usually don't have printed packages (step 4) until after the packaging photo shoot (step 3). This is where our team put our heads together to challenge process and find the loop hole. After structure was finalized (step 1), we had the graphic design template started, only finalizing the front panel that would be shown face up in the caddy photo. I then created 2 printed packaging samples in Minneapolis and next-day-aired them to the photo shoot at Todd's studio in NYC. They made it on the last day of the shoot and were able to be incorporated into the back-of-pack layout!

Sustainability focus

Hand Made Modern aspires to welcome, empower and inspire crafters through bold, cheeky, playful product. Maintaining an environmentally friendly was also a priority when developing the ecosystem and definitely came to life through structural packaging choices. Goal was to not use any plastic packaging materials in the entire assortment, exceptions being around plastic used for storage or reuse (i.e. plastic paint bottles).

We were largely able to achieve this goal, through creative application of unconvential packaging materials including tin, cotton, glass and composite board.

We were inpsired by mesh bags used on produce for the packaging solution for this item. While the mesh used on fruits was a plastic mesh, we found a cotton mesh that fit the voice of the brand and was strong enough to contain the product.

A round tin container was a great storage solution for the sequins and paillette items. The challenge came in that we wanted to get credit for the colorful product. Our solution was to add a clear plastic window - an example of the give and take most businesses face between sustainability and driving sales.

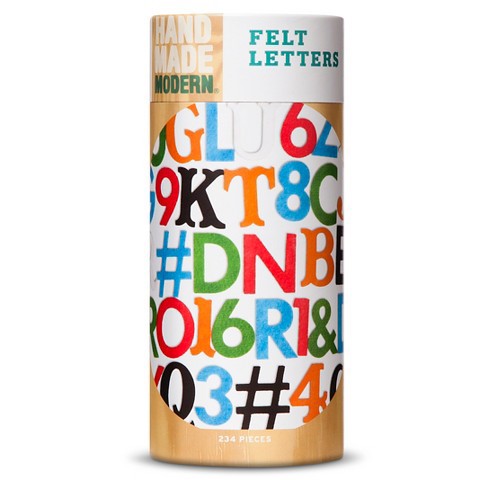

Composite board canister was used for the felt letter items. This format will provide a great storage solution for a high piece count item that does not get consumed in one use.

Comfort in ambiguity and working differently

Immediately upon learning of the program, the packging cross-functional team (copy writing, graphic design, project management + I) went out to evaluate the crafting market to understand packaging on an area of product we had little experience with. I then came back and started sketching out concepts against the early concepts I got from product development. This is a photo of a quick board I had put together to discuss structural packaging direction with the business and cross-functional team. Not super refined, but a great tool to make sure we were all in-sync on the direction.

One of the ways we worked quickly and differently was collaborating closer with our vendors. Sample feedback ususally takes weeks for the Target team to gather, communicate and discuss with the vendors. Our team completed all feedback with all vendors in less than 1 day by walking through feedback item-by-item in-person with all technical areas of excellence present (design, product engineering, packaging engineering and Todd). Here is a snapshot from one of the sessions.