Project for the course Advanced Prototyping in KTH, Stockholm.

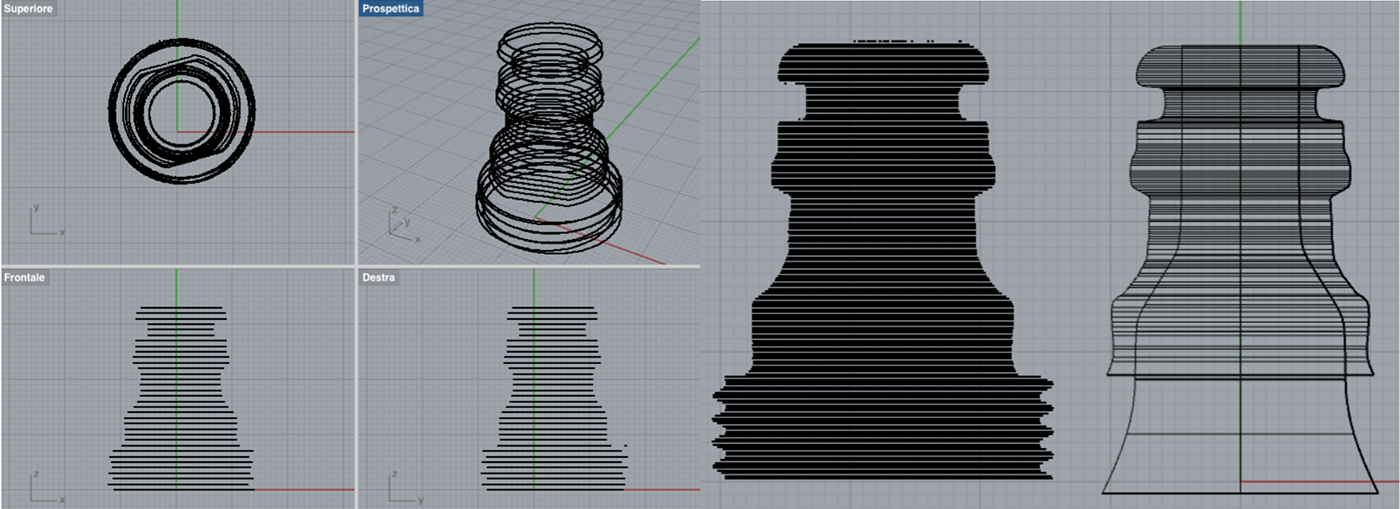

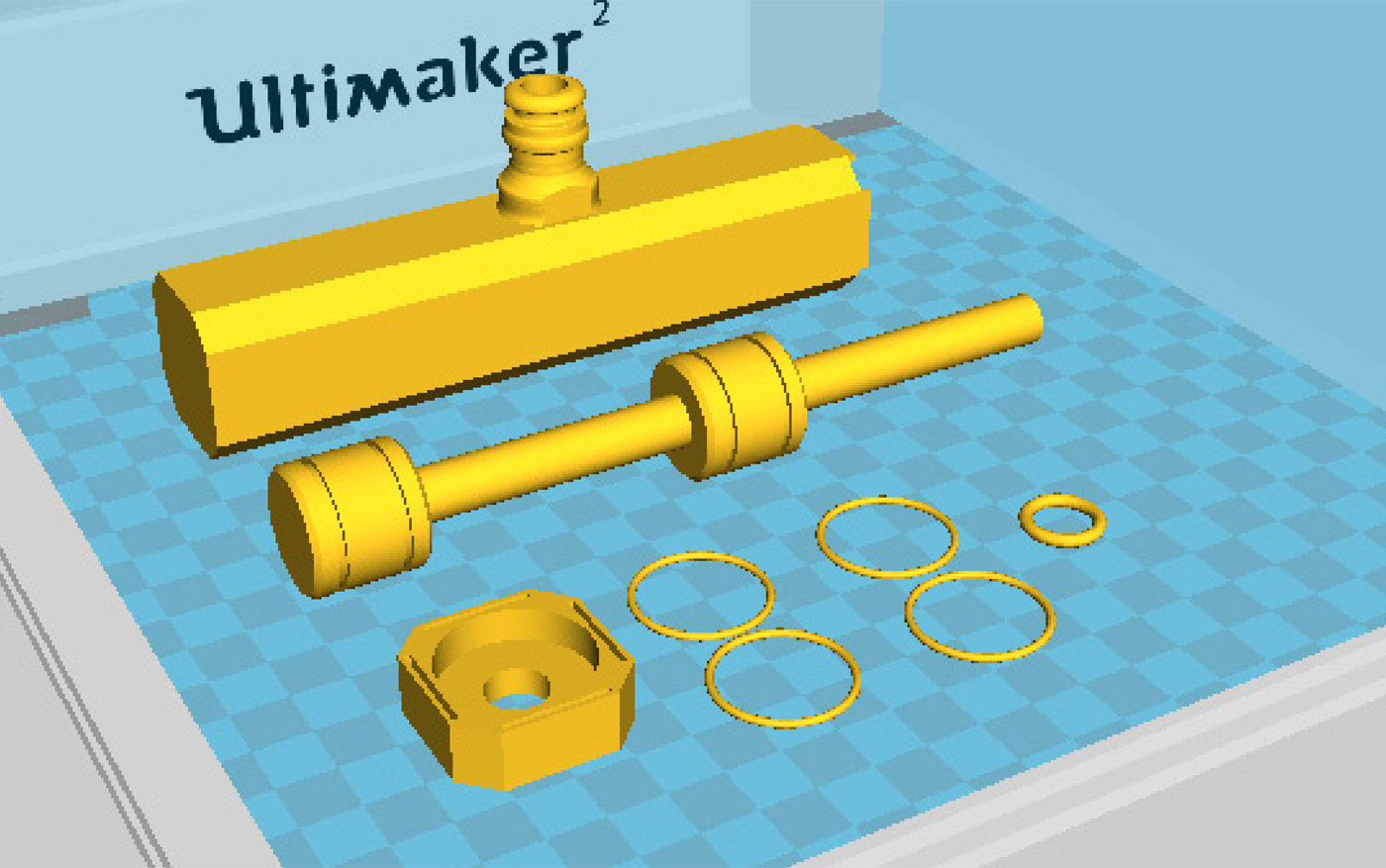

Object designed after the process of Reverse Engineering of a Gardena hose connector with a Roland LPX-600 and Rhino modeling.

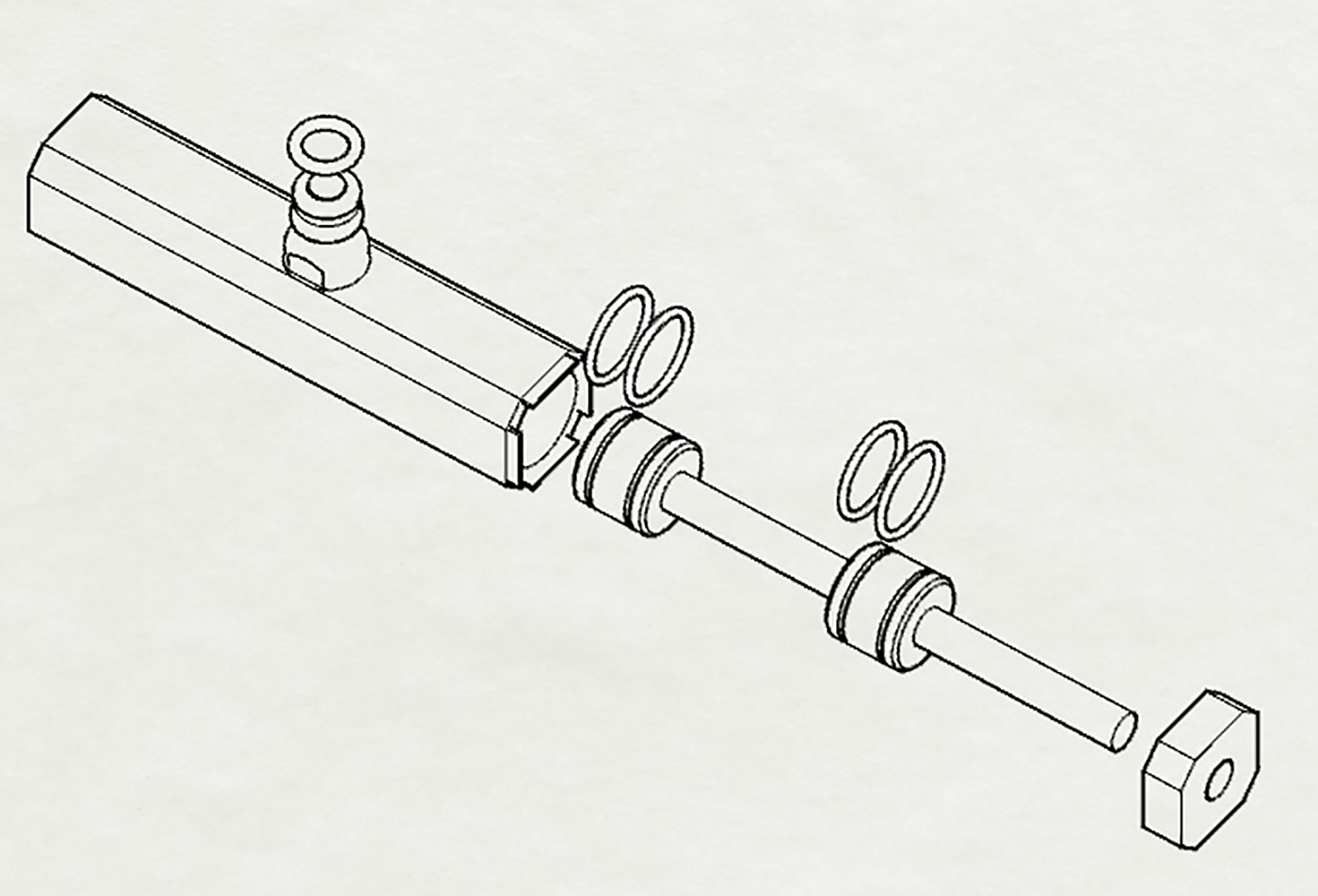

Printed in PLA and ABS with a Makerbot Replicator2x and an Ultimaker2 for the tests, then printed in an SLA printer: Formlabs Form 1+ in Clear Resin. Sealing rings printed in the Ultimeker with NinjaFlex material.

The goal was to integrate a part got after Reverse Engineering working, and make a3D printed model watertight. It works.

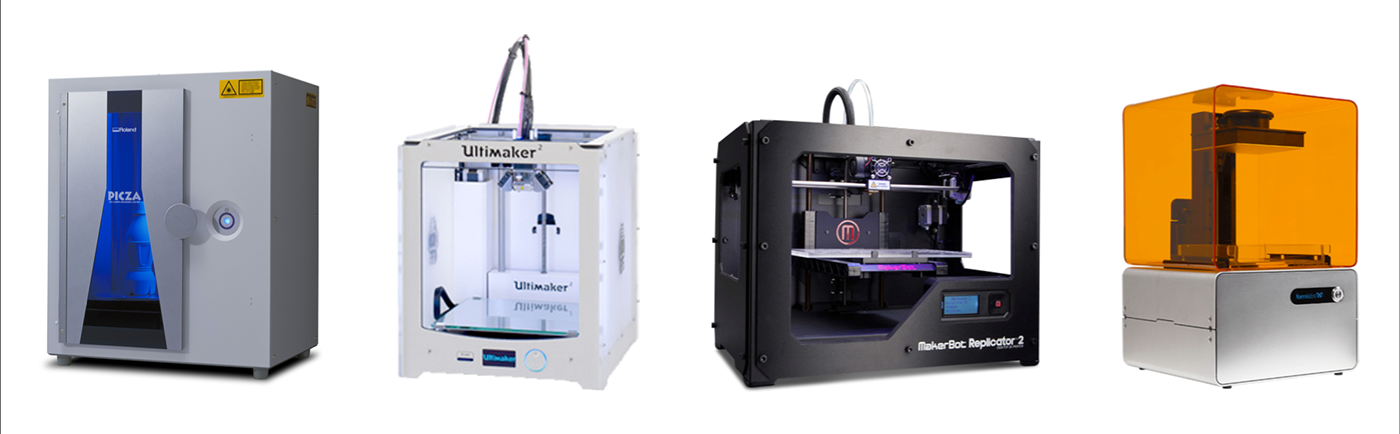

The machines used:

Roland LPX-600 3D scanner, Ultimaker2 FDM 3D printer, MakerBot Replicator 2x FDM 3D printer and Formlabs Form1+ SLA 3D printer.

The Gardena hose connector had been 3D scanned with the Roland LPX-600 3D scanner, having as a output a point cloud file that had to be transformed into a 3D solid model and connected to our water Twin Tap Connector.

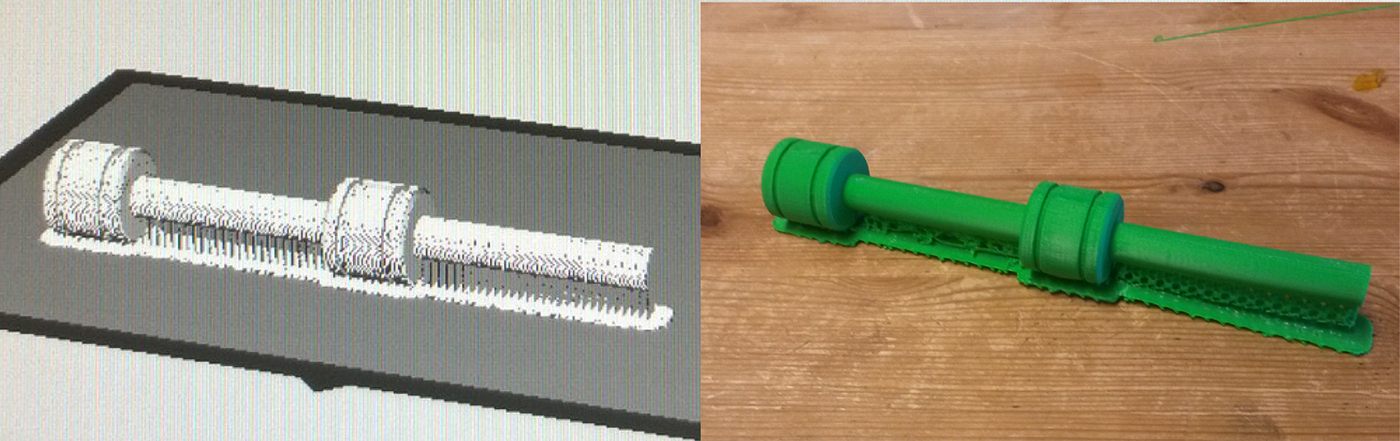

The 3D model had been imported in the Makerbot software generating the G-code for 3D printing the whole set.

The prints had been place in all of the three 3D printing machines in different materials to test the efficiency of both the machines and the materials to resist the water flow.

During the printing in the Formlabs printer we encountered few problems due to the long time of printing.

Even if the object doesn't look perfect, it perfectly works as designed for. The resin printed with the Formlabs Form1+ allows to see the flow of water inside the object and is water resistant.

Project team:

Christian Sedlack

Manthan Shah

Joakim Norman

Riccardo Trimeloni