Hoa Mai Competition 2014 – 2015

The Furniture Design Competition (Blossom Apricot Award) is held by The Handicraft and Wood Industry Association of Ho Chi Minh City (HAWA), Vietnam with the sponsor of American Hardwood Export Council (AHEC), HAFELE (Germany), and some HAWA members' companies.

From 2012 to 2015, HAWA organized 13 competitions. The competition is to detect and foster talented designers. With the expectation of contributing to develop the Vietnam furniture design industry; since then, the Blossom Apricot Award attracts more and more businesses and young designers to take part in.This is a very positive respond.

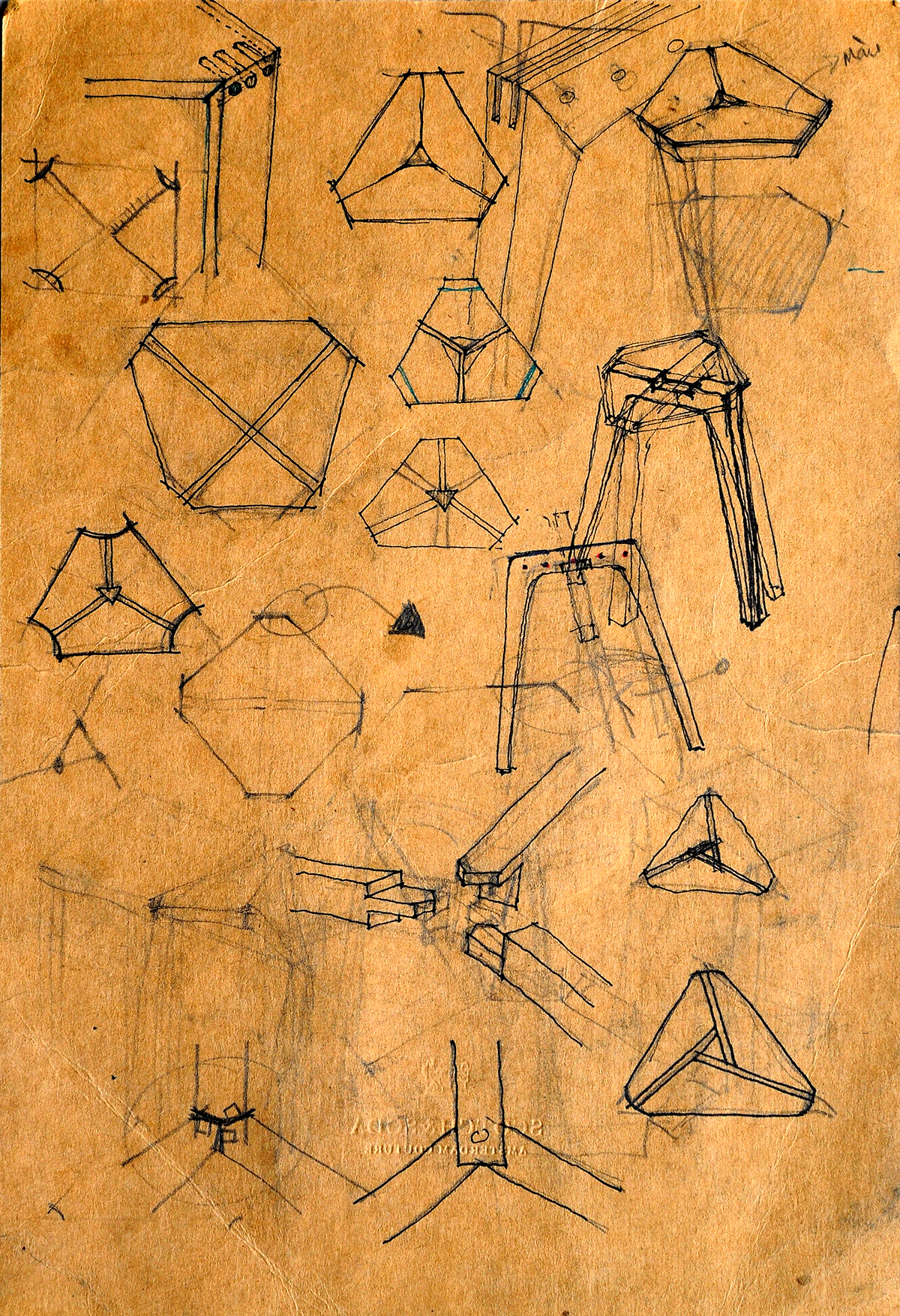

There are two rounds in the competition. In the first round "Giving Idea", the contestants send to HAWA drawings. After that, the Jury board (including the famous designers, architectures in Vietnam and on the world) will choose top 20 ideas into the second round "Producing Prototype". In this round, the each contestant works directly in HAWA members' factory to create the prototype. Based on 05 criteria: Functional, Marketable, Aesthetic, Creative and Unique, Eco-friendly, the Jury board choose 8 best prototypes among them. In this edition, 6 prototypes, wined in the Furniture Design Competition 2014-2015, will be showcased.

"At present, I am working in Ho Chi Minh City and have rented apartment to stay. The biggest obsession of the tenants like me is called "moving". Every time when it happens, it takes a lot of time and effort of mine to sort and pack stuffs. In addition, I have to ask for help with the large-sized and heavy items.Therefore, the cost of moving house is always increasing. From that reason, I have an idea to create a product that can assemble quickly and neatly (Flat-pack design). I named that product under the code "S001" (Set number 1)".

The first product of the HUYS001 is a stool. This stool will be a part of the collection, including stools, bar stools and tables. The original shape looks quite simple with face and legs which can be separated according to each different component to pack and move as gently as possible.

The most difficult job when designing this product is to solve the problem of the joints, in order to detach quickly but still guarantee to with stand the force of the user. Also, the next problem is finding a manufacturer who has capable of creating products with high precision as in the original design.

"The first launched product has chairs made from steel plate and legs from Ash wood. In the next period, with a desire to lighten products, lower production costs and construct in a short time, Ithink of using aluminum sheet materials, plywood and use CNC machines which has 3D

model."

The HUYS001 is for interior use. Target users are the young customers, or those who have displaced frequently.

Construction Unit: Lavanto