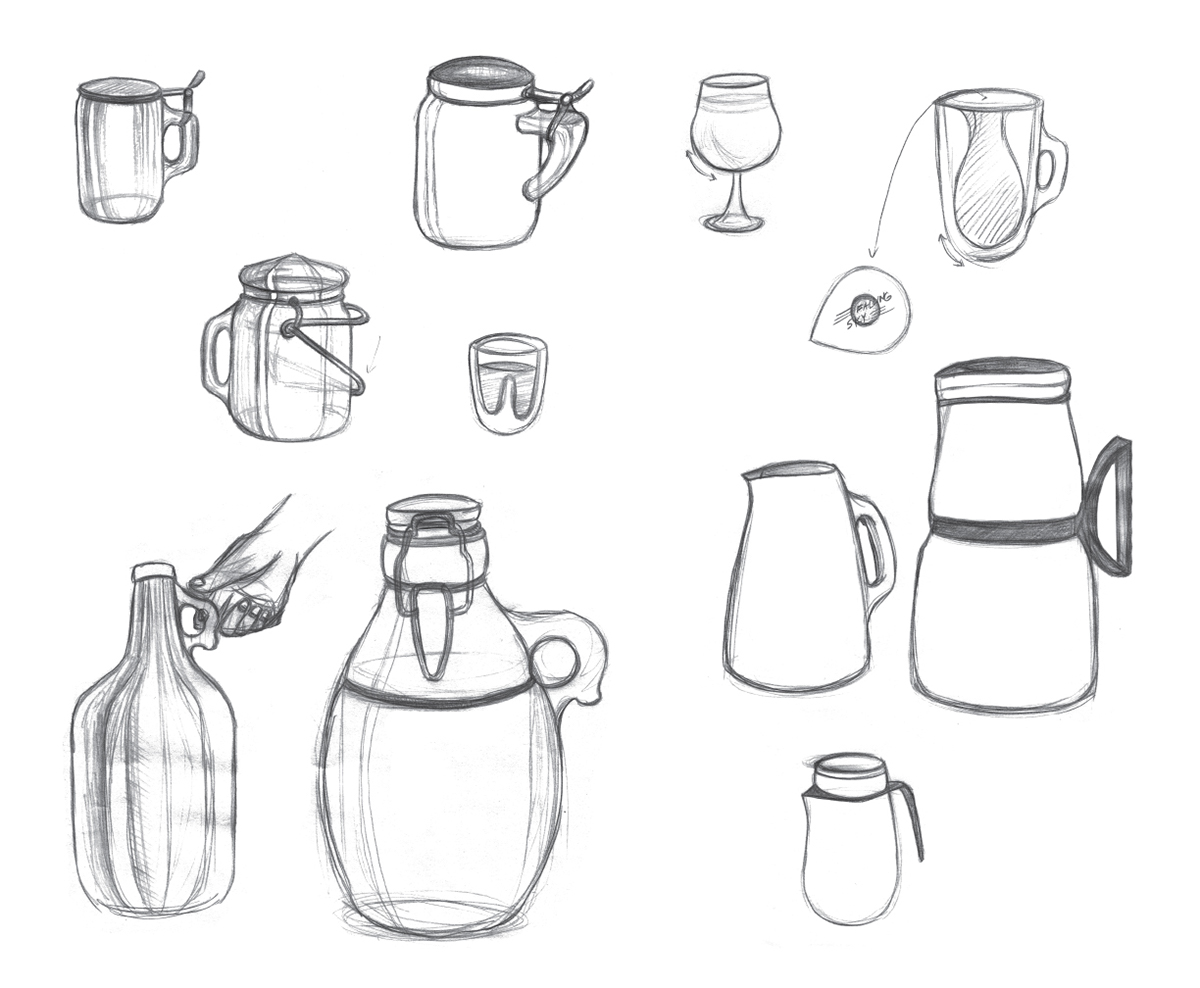

Glass Craft: Needless to say in Oregon, where customers can bring in an empty vessel and take home whatever desired brew they prefer, we love our beer. The class specifically focused on glass vessels for wine, coffee, tea, and water, but we thought it would make for an interesting challenge to attempt and recreate the immutable beer growler. Questions we considered were, how has glass manufacturing capabilities changed? How has our social and cultural habits changed in regards to drinking beer? How can we make a growler easy to carry and transport?

It was our first time reaching out to a local craftsmen to create for us a final product in a design course. Rather than doing it ourselves we worked with Sky Cooper from Sky Tubes of Eugene to ensure that our beer growler was in the trained hands of a glass-blowing professional. Normally a large part of the in-class design process has been advancing our knowledge of a material through hands-on exploration of its properties. Due to the challenging nature of the craft, our primary goal through this project was to find a means of communicating our design intent to the second party in as much detail as possible. Through some trial and error we found out that our initial concept of making an insulated two layer glass growler wouldn’t work with Sky’s machine. Although our final product wasn’t insulated it maintained the other edits to the traditional growler that we had in mind: wider pouring spout, 1 Liter liquid capacity, easy to clean, easily carried one handed.

Design Objective: Design a glass pouring vessel with consideration to brewing, pouring, and serving.Research current and historical solutions to individual persons beer storage. Communicate design intent using illustrations, technical drawings, and a foam model to best inform a second and potentially third party of the design’s intent. Edit drafts until design fits requirements noted by Sky.

Learning Objective: I gained insight into the working parameters caused by limitations to craftsmen’s tools, glass thickness, sharpness of angles, scale, liquid volume, weight distribution, and considerations to easy pouring. It required a certain amount of trial and error, and completely altered our initial design concept. It also pushed Ellen and I to work on our communication skills through more detailed sketches and technical drawings.