4Steps

4Steps is the experimental thesis project for my bachelor's degree in Industrial and Environmental Design in 2017.

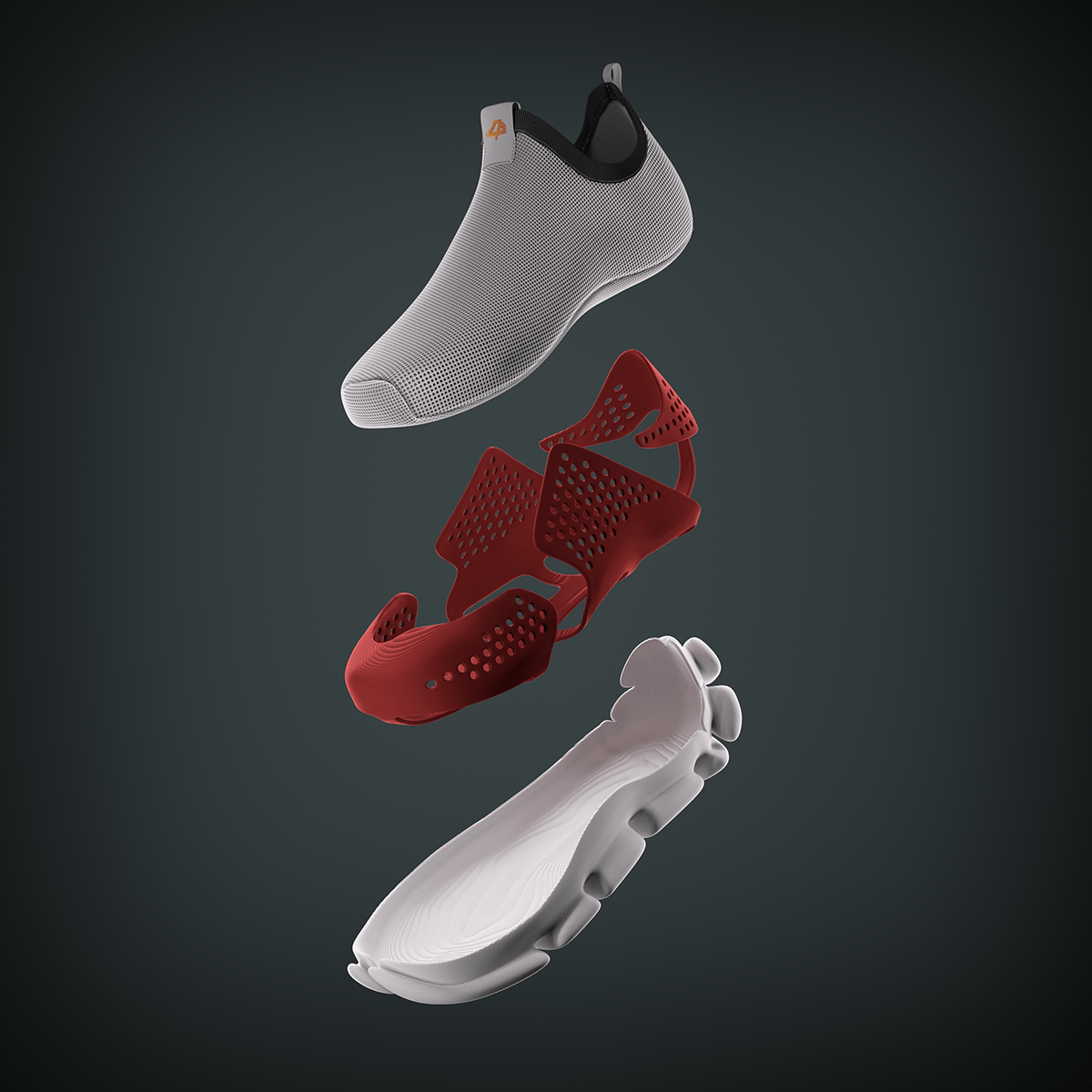

4Steps is an adaptive shoe designed for 3D printing, capable of adjusting to any foot's width, length, and height within a range of 5 sizes. This adaptability stems from its multiple parts that assemble to snugly fit the foot. Primarily aimed at the period of greatest foot growth (ages 6-14), it covers the range of sizes that a child typically goes through in two years on average. The modular design also facilitates the easy replacement of individual parts.

Issue

One of the downsides of footwear is its low level of eco-sustainability. Globally, 25 billion pairs of shoes are produced annually, resulting in carbon dioxide emissions of 340 million tons per year. Additionally, there is a recycling issue at the end of the lifecycle, as old footwear is often disposed of in landfills or incinerators due to non-disassemblable adhesives used in assembly.

Solution

The ideal solution to address the challenges of traditional manufacturing is 3D printing. Besides having no production and formal limits, 3D printers represent a market in constant growth. According to statistics, sales of 3D printers are expected to increase by $6.5 billion by 2030, with a forecast of 100 million printers sold.

Target

The focus is on the primary audience that utilizes footwear most frequently: children. On average, a child's foot grows 1 millimeter per month during school age, necessitating shoe changes every 4/6 months. Consequently, 2/3 pairs of shoes are purchased for each child annually. With 2.2 billion children worldwide, constituting 31% of the world's population (Unicef report 2014), 4.4 billion shoes are produced and discarded annually.

Weight

The shoe features molded parts with a honeycomb structure, making it significantly lighter than typical footwear soles (only 132 grams), while maintaining compression resistance.

Sole

The sole's cleat design enhances stretchability and accommodates the foot's bending points for proper flexion during steps.

Customization

Color selection depends solely on the printing material. The shoe can be ordered via a dedicated online configurator from the manufacturer or downloaded as a file for personal 3D printing, allowing children to choose the color. Customization extends to the embossed logo, offering preset options or the ability to upload a personal logo. The laces provide children with complete freedom to configure their shoes, enhancing both functionality and playfulness.

Prototype

Initial rough prototypes were 3D printed with Filafex (TPU) filament, providing softness and durability, with the sock crafted from a 3D technical fabric used in automotive.

Some details