HARTO: Agricultural Mobility Assistance Services

Harto is an autonomous utility vehicle that offers greater convenience in the various stages of agricultural practice. Designed and thought out according to the needs of the farmer in the environment for which it is intended, in order to facilitate the entire agricultural development process.

Harto's aim is not to inhibit the farmer from his duties, as this would be unthinkable for our producers, but rather to assist in the whole process in order to ease the physical burden of the processes associated with agricultural practice,

PART I: Investigation

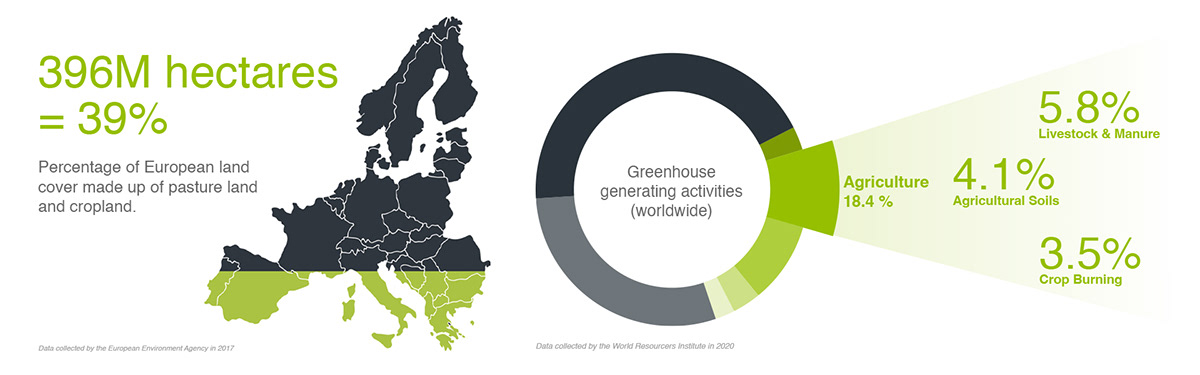

Agriculture is one of the most important economic clusters of the 21st century, with significant global representation. This greatness is accompanied by a number of challenges in terms of sustainability and environmental issues associated with this sector. Harto aims to meet the sector's needs, as well as being an efficient and positive response in terms of its environmental footprint.

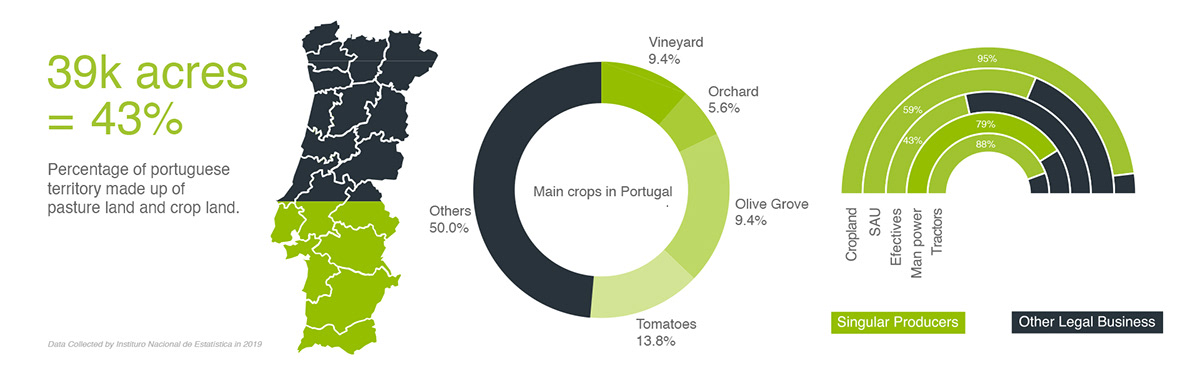

Portugal was the country chosen for the project's intervention. 43% of the country's geographical area is covered by croplands, 30% reserved for extensive agriculture and 13% for intensive agriculture.

Extensive agriculture is the main focus of this project because it depends closely on local farming communities working together to manage logistics and local productions, which most of the time depend on limited resources and budgets. In addition, one of the factors that accompanies this type of agriculture is the fact that it is practised by an average number of senior citizens who have limited physical capabilities.

Based on extensive research using various methods, such as interviews, user journeys and field trips to the project site, the problems that Harto had to solve were identified and defined.

The main problems lie in the way the agricultural fields in the sector under analysis are managed and cared for. The vast majority of agricultural crops depend on a central means of distributing goods, also known as "cooperativas" (Regional / local shops), to help local farmers with material goods. This dependence leads to a lack of associative spirit among the producers themselves and hinders crop productivity. Another notorious aspect is the number of physical problems that are generated by agricultural work in the farmers themselves, as well as accidents at work that somewhat limit the productivity of these crops.

To summarise , the problems to be solved are: Physical problems in agricultural producers; Low productivity of local extensive crops; Lack of associative spirit in farming communities; Sustainability problems linked to poor agricultural practices.

PART II: Product Development

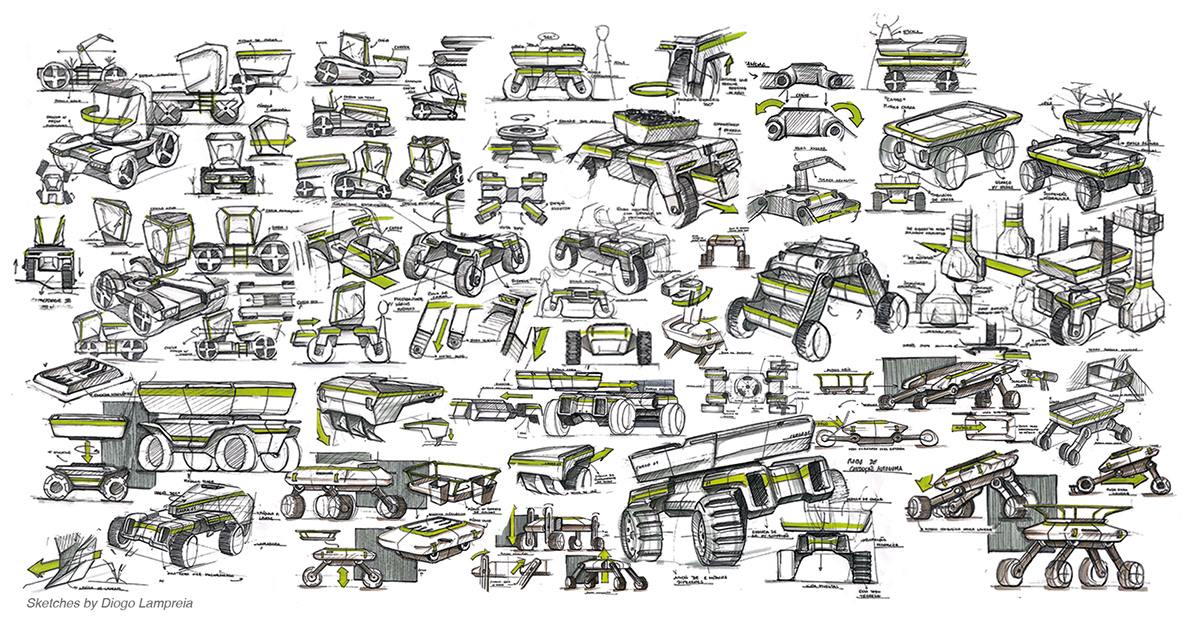

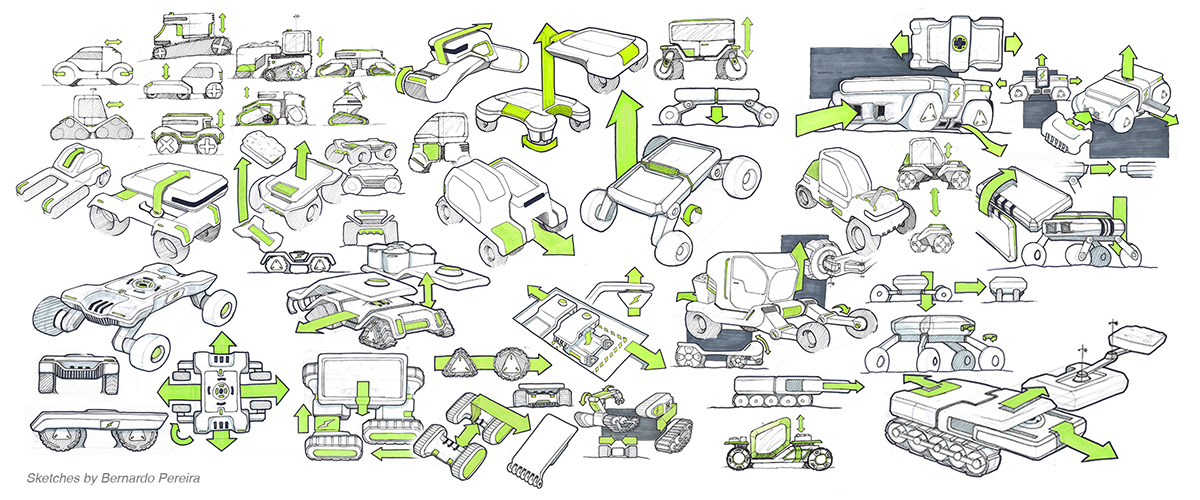

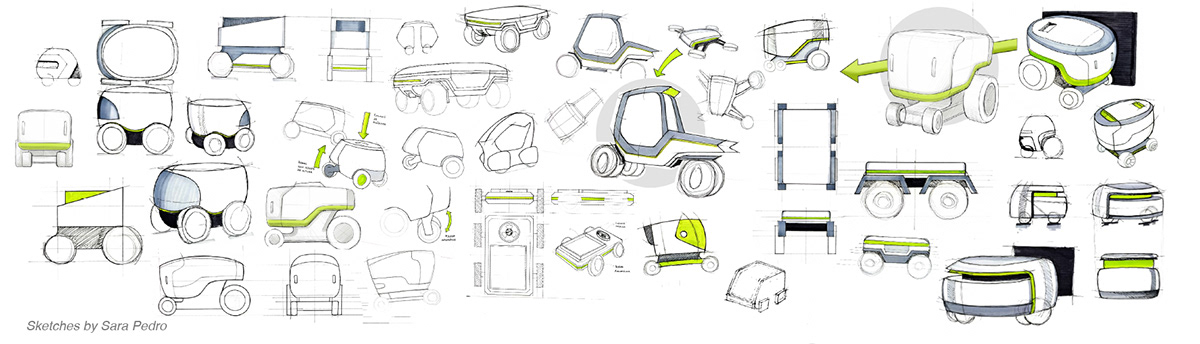

For the development phase, the group discussed and exchanged ideas in drawing sessions to cover as many hypotheses as possible. From the outset, a moodboard was established that would then serve as a guideline for the visual visual representation of each idea.

CONCEPT DESCRIPTION: Diogo Lampreia

It is an autonomous, 100% electric vehicle that acts as a base for the various modules destined for each production phase. The connection is made by means of magnets and latches on the top of the vehicle, allowing the various modules to be coupled by means of a specific support system.

CONCEPT DESCRIPTION: Bernardo Pereira

This vehicle is 100 electric and has modular features that allow it to carry out different tasks at the same tasks while maintaining the same base. The mechanics is designed for the conditions of use, such as raising and lowering the base to make it easier to change the modules, and for the conditions of the terrain, such as the self-shaping wheels between tracks and all-terrain tyres. all-terrain tyres.

CONCEPT DESCRIPTION: Sara Pedro

It is a 100% electric auxiliary vehicle that works as an autonomous light transport robot. It is used for smaller jobs during the agricultural process (soil sampling, planting, maintenance and harvesting). Its storage, although reduced compared to larger vehicles, saves the user the physical effort of carrying tools and even the harvested harvested products.

PART III: Service Development

The service will be made up of a network of operators that are strategically placed in various rural areas of the country, where extensive agriculture is practised in high volume. The services offered by the operator ensure a large part of the agricultural process, from the soil, planting the crop, maintaining maintenance and, finally, the harvesting process.

Each operator has a fleet of autonomous depending on the number of workers, and, in turn, different modules for each for each stage of the cultivation process. The process is effective and is believed to be advantageous for promoting quality and safety at work of those involved in agriculture, without completely removing completely from the intervention of Man.

PART IV: Materialisation and Visualisation

More control, productivity and safety in crops and agricultural practices.

Harto is an autonomous utility vehicle that offers greater convenience in the various stages of agricultural practice. It has been designed and thought out according to the needs of the farmer in the environment for which it is intended, in order to facilitate the entire agricultural development process. Harto's aim is not to inhibit the farmer from his duties, as this would be unthinkable for our producers, but rather to assist in the whole process in order to ease the physical burden of the processes associated with agricultural practice.

Range of modules

The modules developed for Harto correspond directly to each of the different areas of activity designed for the vehicle, from soil preparation to maintenance and finally the entire harvesting process.

The initial range of modules represents just one part of the countless possibilities for Harto modules, since many more can be adapted for the vehicle, depending on the needs of the users.

Cargo Module

The cargo module, as the name suggests, is designed for loading goods during the various agricultural production processes. This particular module attaches to the top of the vehicle and has 1.35m^2 for loading with a height of 0.5m, to ensure that all goods are loaded safely and stably. It also has two side-opening doors that occupy the entire longitudinal part of the module, so that the transfer of goods is as homogeneous as possible.

Cockpit Module

As well as ensuring the user's comfort during use, the seat gives them the option of manually controlling the vehicle via the simple dashboard. In terms of comfort, the seat has a shock absorber built into the underside so that the forces placed on the user are minimal. It also has a manual foot adjustment that allows the seat to be adjusted to the user's height.

Plow Module

The plough has the function, as the name suggests, of ploughing the land, and belongs to the components that make up soil preparation. The plough consists of 6 longitudinal mouldboards that are in direct contact with the ground to ensure soil preparation. As this is a module that exceeds the length of the vehicle, two reflector lights have been incorporated for safety reasons.

Tree Collector Module

The collector is designed to harvest tree crops by vibration through the attachment of two claws, that can attach a surounding net , so that all the collectibles stay inside of it. This module fits horizontally into the vehicle, where the energy is transferred to power the vibration motor and it can be used on both sides of HARTO, as the user pleases.

Drone Module

The drone's function is to provide support during the use of the Harto in the various services it will perform, such as mapping the route beforehand, visually mapping the terrain of operation, ensuring the location of the Harto on site, among others. The drone lands on the vehicle on a charging platform that attaches to the top of the vehicle, which ensures that the drone can be used for several hours at a time.

PART V: Outsource technology and funcionalities

Active Suspention System

This allowed a wider range of drivers to experience the benefits of active suspension, which included improved manoeuvrability, stability and comfort. Active suspension systems use advanced sensors and computer systems to adjust the suspension in real time, resulting in a smoother and more comfortable ride. Different axes of rotation offer active suspension for obstacles and inclines on all types of terrain. This enables the vehicle to operate on a wide range of terrains, whether rough or uneven, in order to guarantee the service to be provided.

Internal Components and Charging

HARTO's most notable internal components are its chassis, which supports the entire body and ensures that the vehicle's various internal systems are joined together. It also supports a battery pack that powers the four electric motors, each on each wheel of the vehicle.

The batteries are charged on specific platforms with induction technology, where through physical contact the energy can be transferred from a reservoir to the Harto, simply by activating the charging mode. In charging mode the rotating axles of the wheels move down the body to allow Harto to be near the energy base.

Storage and Acessability

Cargo spaces on the side of the body make it possible to transport hand tools and liquid products. The side panels when in a low position after 90º manual rotation are supported by load cables and provide a support platform for any activity requiring a workbench or horizontal support. The load cables, when the side panels are raised, can be used as a means of securing longer hand tools, such as shovels, rakes, fillers or other similar objects.

LIDAR System and Sensors

Harto uses a Lidar Radar system, this is a remote sensing method that uses laser light to measure distances and create detailed 3D maps. It works by emitting laser pulses and measuring the time it takes for the light to reflect after hitting an object. LIDAR is commonly used in applications such as autonomous vehicles, terrain mapping and environmental monitoring that work.

It also is equipped with infrared sensors on both front/back and sides of the vehicle. These are devices used to detect the presence or absence of objects within a certain range without physical contact. They use various technologies, such as infrared, capacitive or inductive detection. These sensors emit fields or and measure the changes in the field or beam caused by the presence of an object.

Lighting

The lighting is based on LED strips and comes in 3 different colours: neutral, red and amber. Each of the tones is linked to a function: neutral for normal night-time lighting, red for brake lights and amber for flashing warnings, as seen on the images.

PART VI: Mockup model and Presentation

The model was built using 3D printing technology. Printing was divided according to the structure of the part to be printed, with more complex parts opting for SLA printing and less complex parts opting for FDM printing. The parts were then finished and unified to form the respective model.

The final presentation was held at university and it was composed of two informative posters, one project book, one technical drawings book and the respective mockup model.

Designed by Diogo Lampreia, Bernardo Pereira, Sara Pedro

Faculdade de Arquitetura U.Lisboa - 2023