Pilot Translating Earbud

I spearheaded the design and production of the Pilot Earbuds, a remarkable product that marked my journey into the wonderful world of Electronic Mandufacturing and Design in China. This product combines ergonomic excellence, robustness, reliability, market appeal, and manufacturing efficiency. With a staggering sales record of over 48,000 boxes, and over $ 8 Million USD in sales. I was responsible in every aspect regarding product; from designing the specs to overseeing shipment and support. Our achievements include 1 patent, 8 certifications, and 3 international design awards. Collaborating with exceptional partners in Shenzhen, China, we ensured top-notch quality, CMF perfection, manufacturing optimization, and outstanding audio performance.

I took a lot of prints from users that were in our target gropu. These prints had 3 reference points for alignment.

Initial Sketches and concepts.

Once the prints were ready I sliced them to aquire inputs curves for the geometry.

I averaged all the curves and created an array that later helped me build tangential surfaces to guarantee continuous surface tension and light bounce cleanness

This is not the final piece, but I wanted to show the moldflow analysis. This was an early stage design.

Testing Fixtures in the assembly line

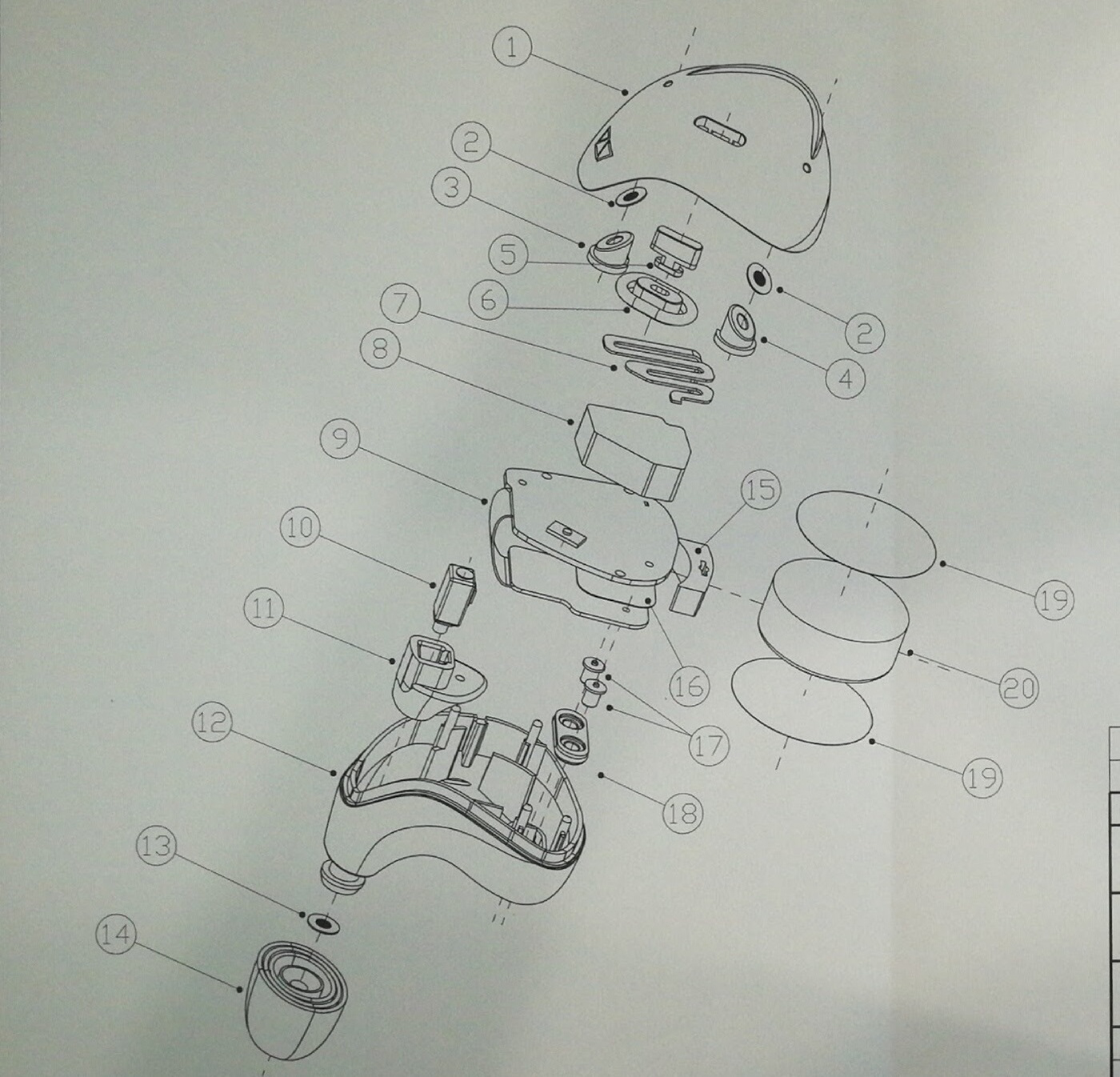

These are not the final designs, but they are a great reference of the documentation we were creating, these maps were invaluable during Pilot Production Runs and Procurement

Our friend here, helped us test the microphones and voice capturing in a controlled environment, that helped us tune the mics appropriately

After hours of meticulous observation I approved final prints for the offset production, color balance, tone, saturation, alignment etc. You want to be sure before printing 50,000 copies

Lots of prints

Tooling before polishing or surface treatment.

The early transparent units helped us validate the appropiate assembly of all the elements and check the antenas weren´t disrrupted by the shell.

Tunning the microphone drivers, the river manufacturer provides you with calibration software and you have to tweak some parameters to optimize for your particular use case. Parameters like wind suppression, filtering algorithms, etc. are all taken into account.

Getting ready for the Pilot Production Run

Testing Chargers

Early mockups of the User Manual

Boxes and boxes of finished products. I had to apply for our Bar Codes with GS1, a cumbersome process, but I'm an expert now. Every level of packaging requires a different bar code. Having this properly implemented, saved us a ton of time and cost in the warehouse.

Our wires were customized too, they had a flat profile, and our logo embossed.

First injection pieces for the charger.

Making sure everything as working as intended befor approving injection of all the pieces.

Me posing and using a mirror to check the look of the design. I have a weird ear heheheh

Renders I created in Keyshot that we eded up using for everything; press, marketing, documentation, user manuals, etc. This renders were pretty cool back in 2018