FIBERFLAX: The new bio-composite for furniture made of wool and linen from the Sardinian traditional crafts

FiberFlax was born as part of my final project for my BA in Industrial Design.

The concept was born from the objective of creating a new eco-friendly composite material that could replace fiberglass in the construction of furniture that could be produced with local, sustainable materials from the Sardinian craft tradition. Infact, nowadays it is important to understand the impact that any design has on our planet in terms of energy consuming and exploitation of resources. This is why it is the designer's task to find solution to these problems by finding new way or materials to rethink everyday furniture. This is why flax and felt were choosen.

After an extensive research on different types of materials, the choice fell on felt, flax and a particular type of ecological resin. Linen and wool felt, in the last years, have appeared successfully in world of bio composites: flax located increasing use in industry automobile as a valid substitute glass fiber, the felt instead as insulating material and filler in the field of 'civil aviation and transportation goods.

This choice has been addressed thanks to the analysis of different materials and through some criteria that could respond to low environmental impact: they consist in harmful toxicity of the materials; the naturalness of the materials; waste management; renewability of resources.

This choice has been addressed thanks to the analysis of different materials and through some criteria that could respond to low environmental impact: they consist in harmful toxicity of the materials; the naturalness of the materials; waste management; renewability of resources.

Furthermore, a feature that influenced significantly in final choice is that both of these materials

natural are present in the Sardinia Manufacturing tradition. Startingfrom the linen produced in the village of Busachi, country of central Sardinia renowned for the processing of this

vegetable fiber, to the felt in village such Bitti in the Sardinia Midlands.

natural are present in the Sardinia Manufacturing tradition. Startingfrom the linen produced in the village of Busachi, country of central Sardinia renowned for the processing of this

vegetable fiber, to the felt in village such Bitti in the Sardinia Midlands.

Linen is a material widely used in the Sardinian tradition for the making of fine hand-made carpets and clothes of fine making. Its plant requires very little water along all its life cicle, and where planted, helps to drain and purify the soil. and as if that was not enough it consumes 7 times less energy compared to glass fiber!

Wool felt instead was choosen to act as an interface, and so get the material stronger, and also for its property of absorbing heat, providing to the user a warm wood-like sensation. At last wool felt is derived from waste fibers obtained during the process of production of wool for clothing. For what concerne the resin used to bond these materials, a special kind of sustainable resin was choosen, made of recycled oils and wood pulp.

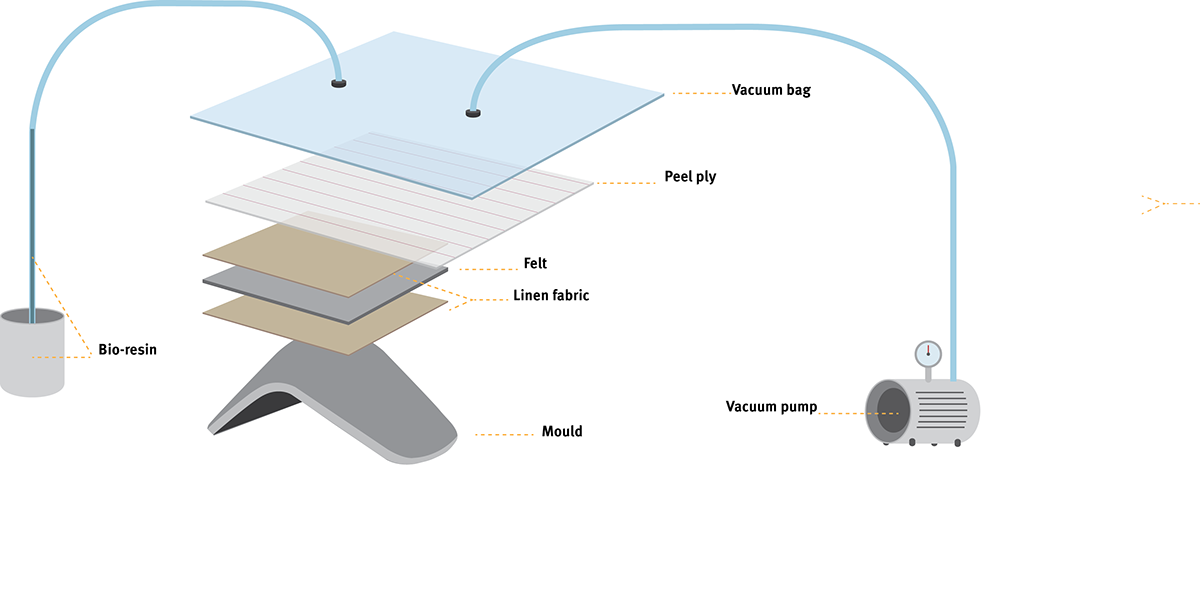

The process used for the development of this material is a technique borrowed from aerospace and automotive, known by the acronym of VARTM ( Vacuum Assisted Resin Transfer Molding ), for the construction of high-performance components. The applied vacuum creates a pressure differential which is used to push the resin from its container to the dry fabrics impregnating them. These technique allow the fabric to absord only the stricly necessary resin, avoiding any waste.

Raw flax fabric and traditional wooden loom.

Sardinian sheep wool felt.

Examples of different colors of the FiberFlax raw material

Scheme of the VART technique used to produce FiberFlax

FiberFlax Stool

FiberFlax Chair