GIDARA Energy

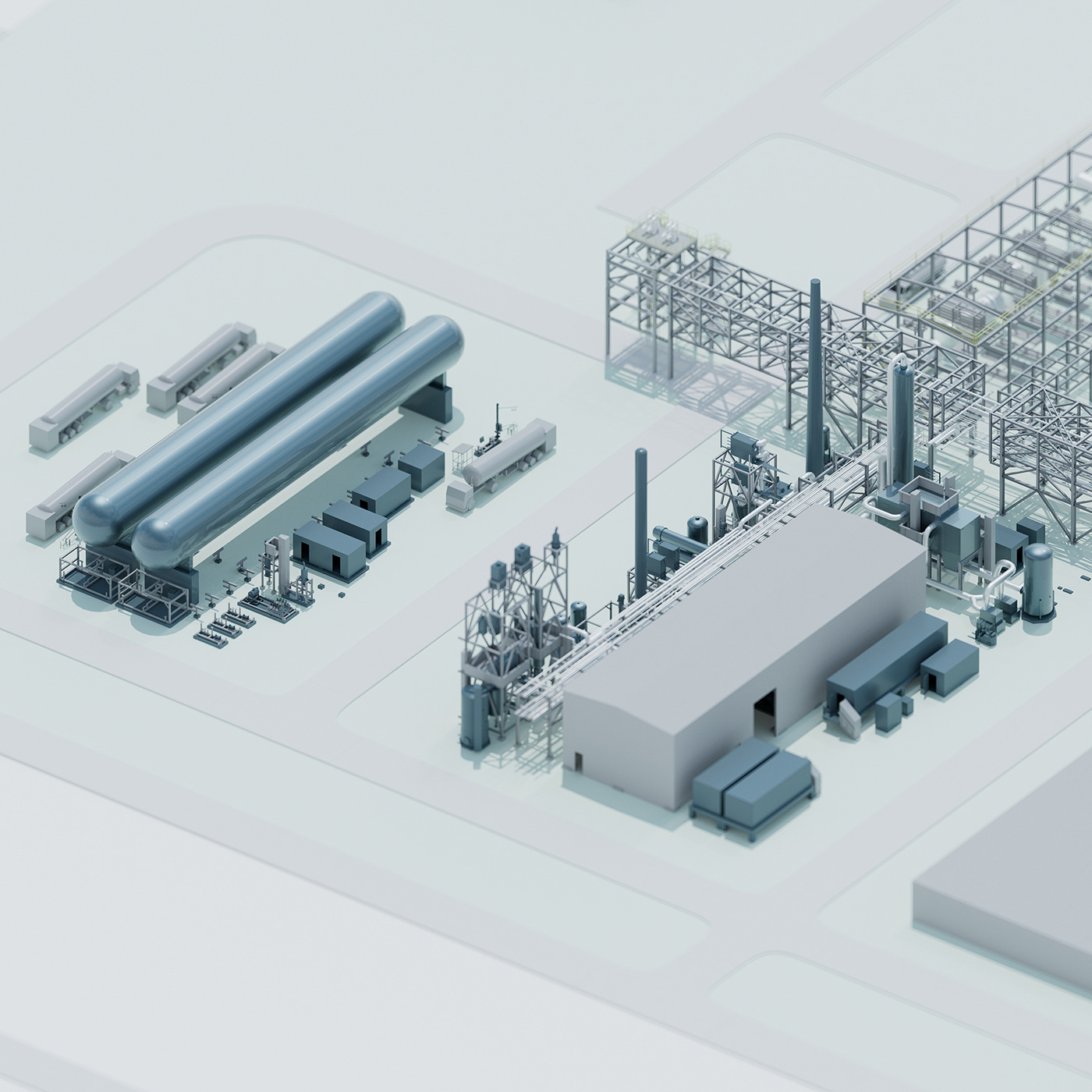

State-of-the-art facility in the Port of Amsterdam.

Completing the first year of our collaboration with GIDARA Energy with another design-driven piece showcasing all the important features of the new facility using detailed motion graphics design.

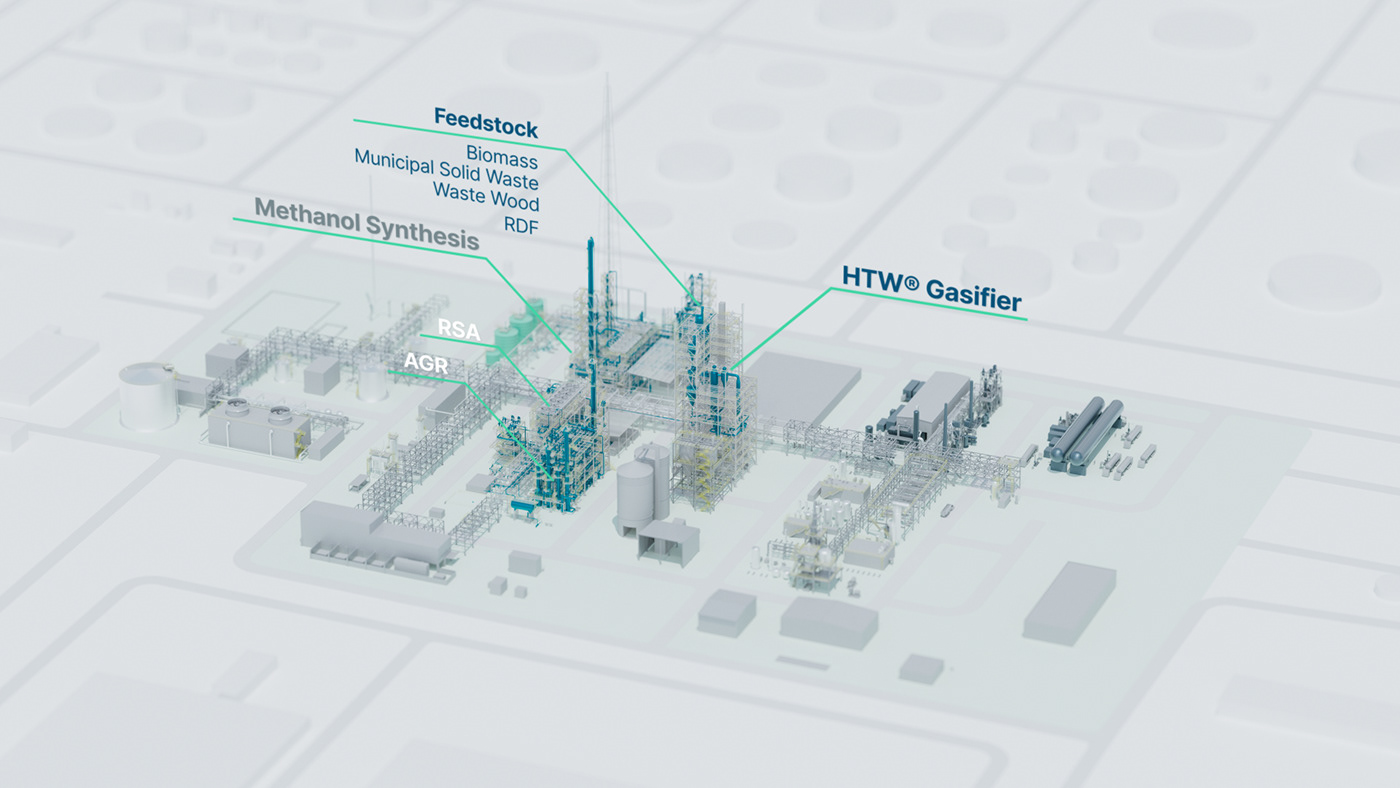

GIDARA Energy’s first production facility will be located in the Port of Amsterdam Biopark (Netherlands) a development location for producers of renewable fuels. Advanced Methanol Amsterdam (AMA) is destined to produce advanced methanol that meets the European biofuel mandate (Renewable Energy Directive II) as well as local, Dutch legislation.

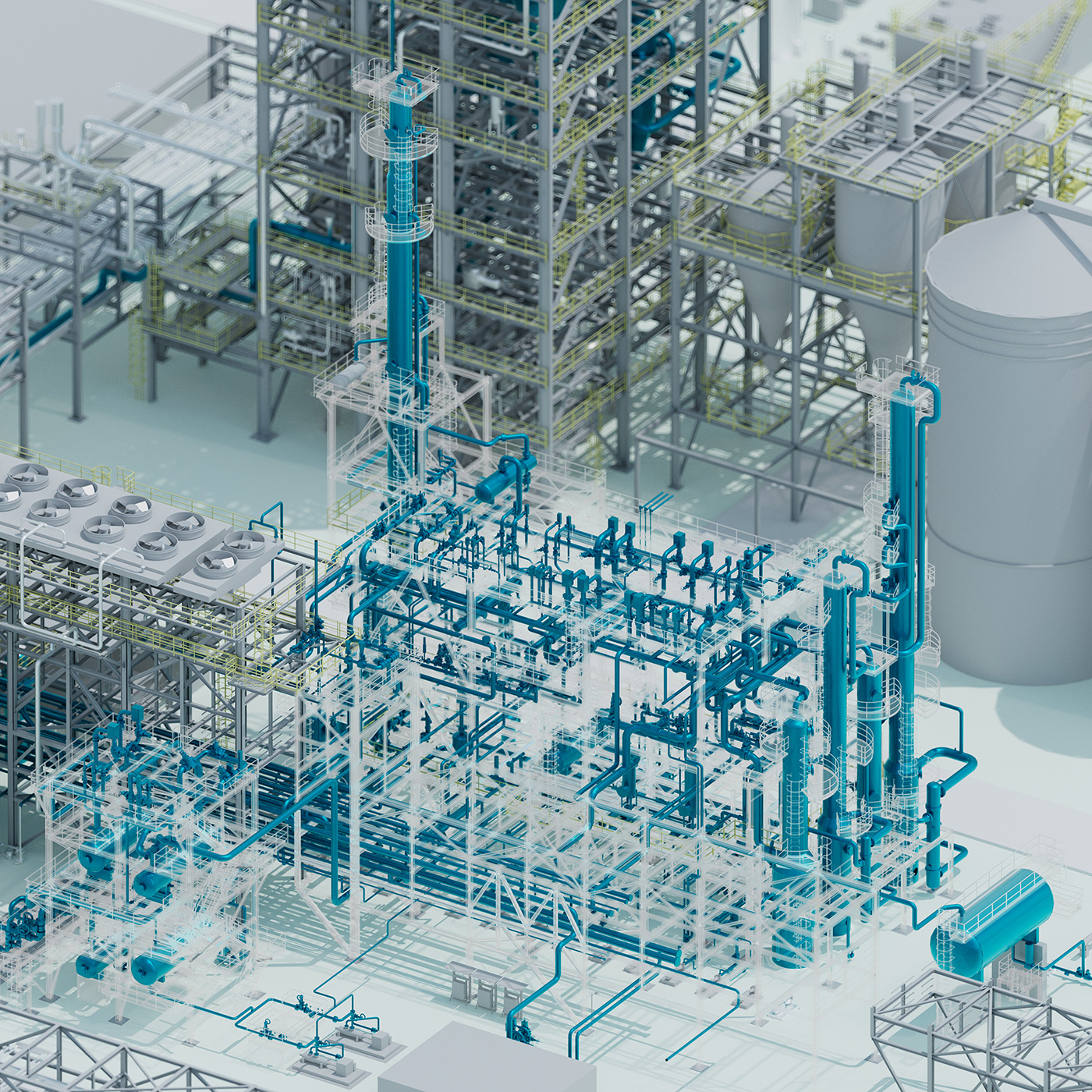

The High-Temperature Winkler (HTW)

This is one of the most developed gasification technologies. In 2019, GIDARA Energy acquired the HTW® from ThyssenKrupp, further developing the technology for modern applications.

Using HTW technology facility will produce an average of 87.500 tonnes of advanced methanol per year by converting non-recyclable waste equivalent to that of 290.000 households yearly, which otherwise would be landfilled or incinerated.

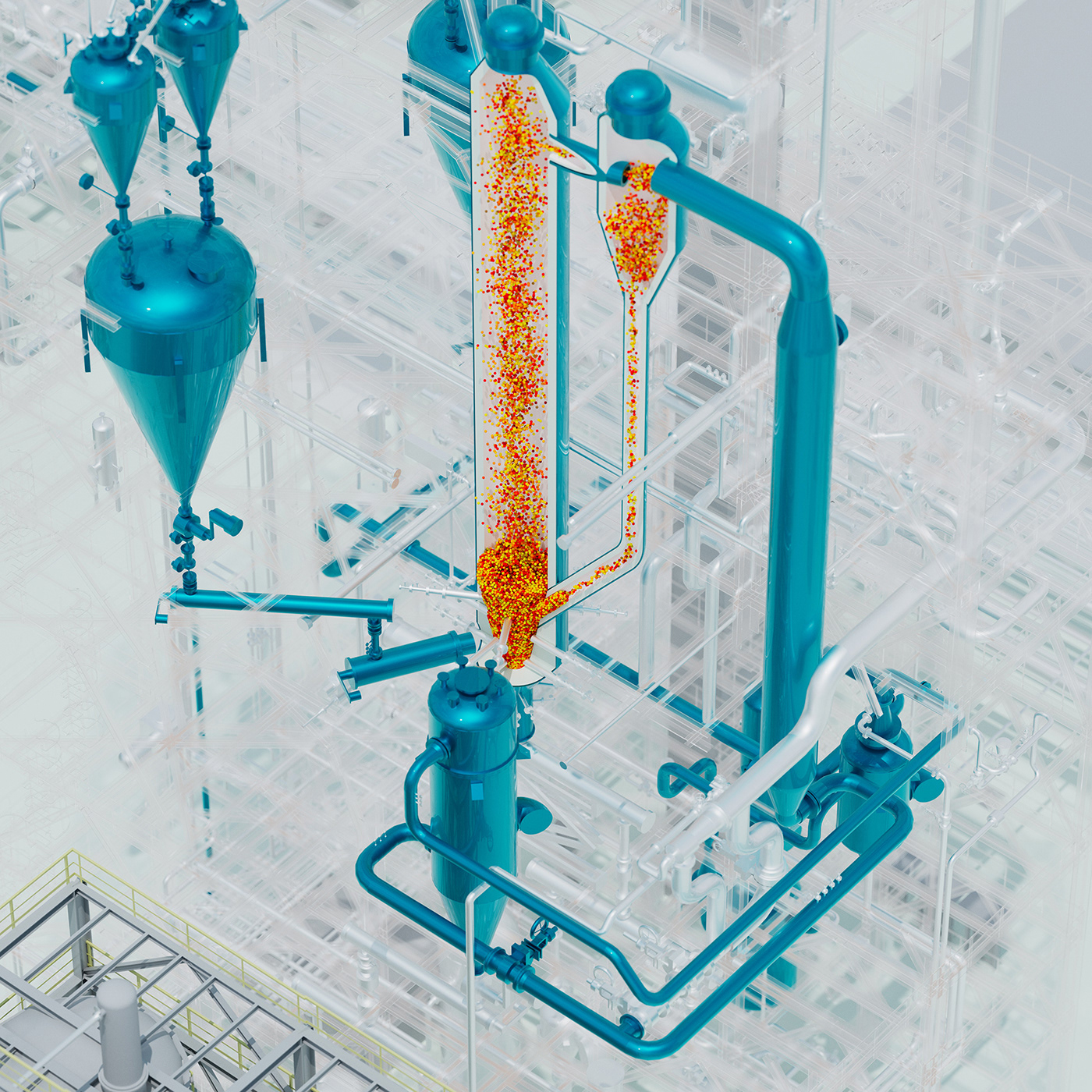

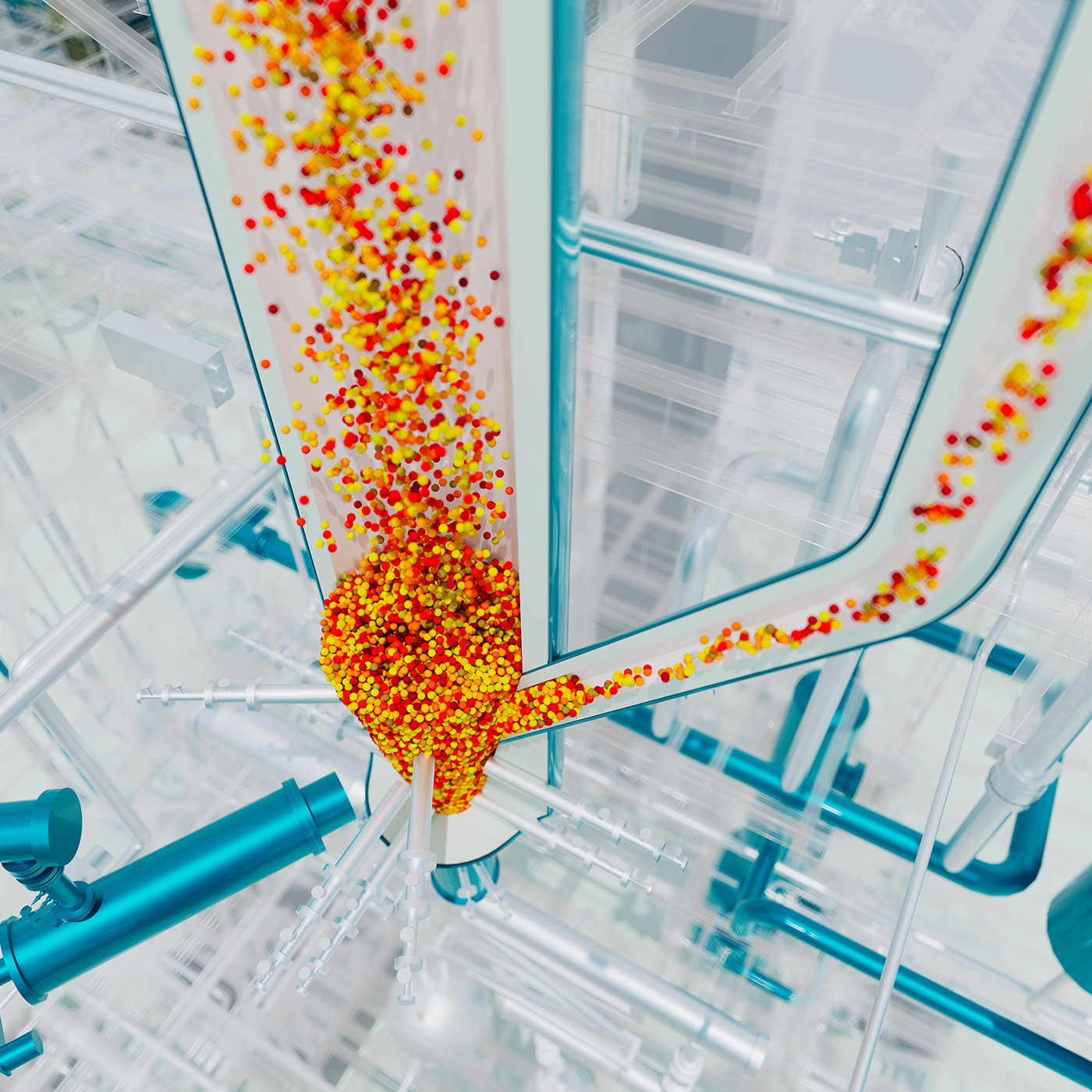

The HTW gasifier is a bubbling fluidized-bed reactor which operates in either air or oxygen blown modes. It is a dry-feed, pressurized, dry ash gasifier. A key advantage of the technology is the capability to gasify a variety of different feedstocks, including all grades of more reactive low-rank coals with a higher ash softening temperature (i.e., brown coal), and also various forms of biomass; wood, refuse derived fuel and municipal solid waste.

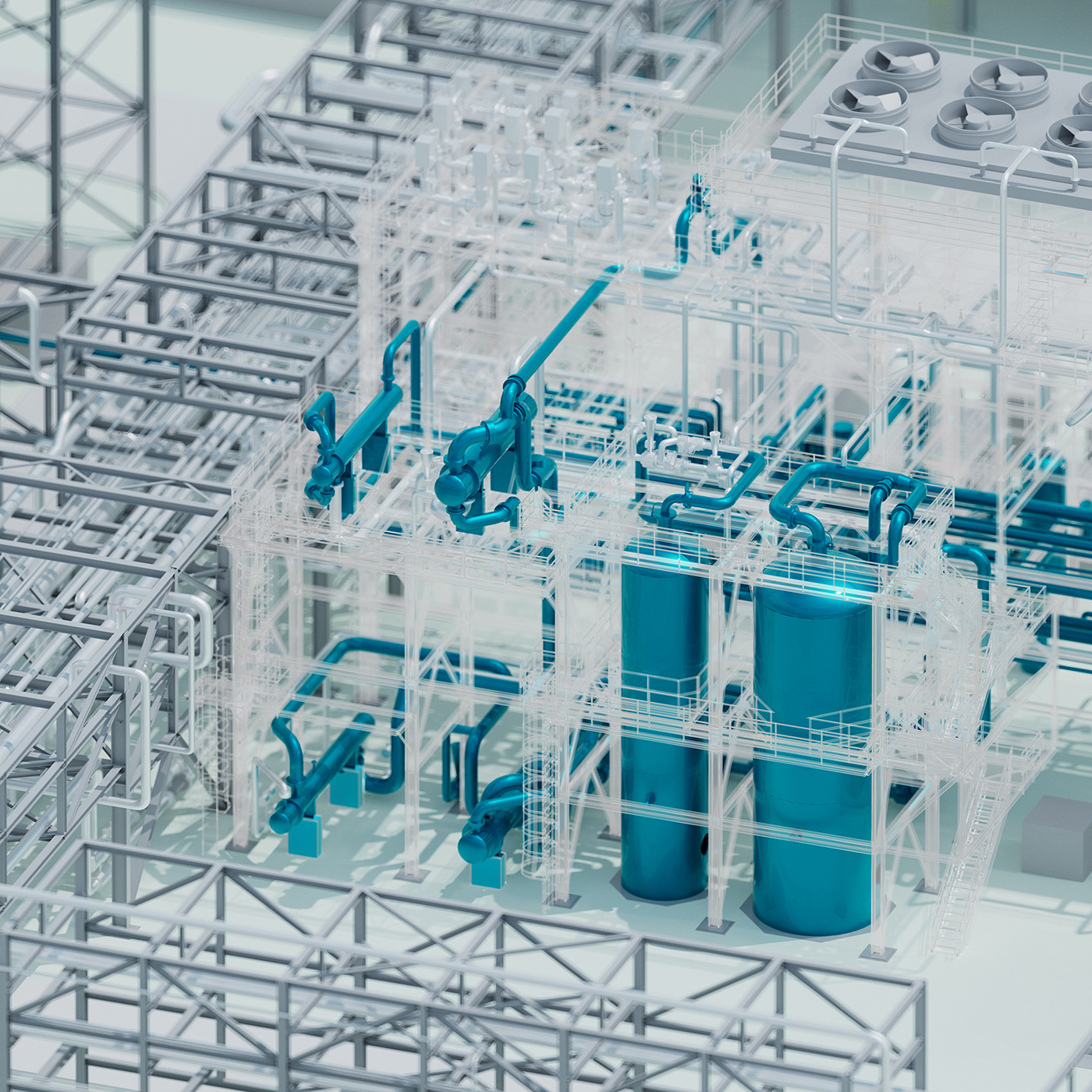

The result of HTW gasification process is a mixture of carbon monoxide, hydrogen and various hydrocarbons called Syngas. The raw syngas undergoes a series of consecutive procedures, commencing with a cooling phase, followed by a thorough cleansing stage to eliminate impurities. Subsequently, it undergoes a water gas shift process and further cleaning. It is important to note that this process is technologically sophisticated, and in the video, we focused on highlighting the key steps involved.

The raw gas scrubber removes the corrosive and partly washes out ammonia and other impurities.

Raw Syngas Adjustment (RSA)

Adjusts H2/CO ratio.

The raw Syngas from the scrubber passes through a water gas shift, where steam is added to the reactor at high temperature which causes reaction that produces carbon dioxide and hydrogen gas.

Acid Gas Removal (AGR)

Removes H2S, CO2, NH3.

The adjusted Syngas is treated with the Rectisol wash technology to remove ammonia and other acid gases such as carbon dioxide and hydrogen sulfide. Rectisol wash technology is a physical acid gas removal process using an organic solvent (typically methanol) at subzero temperatures, what remains is clean Syngas.

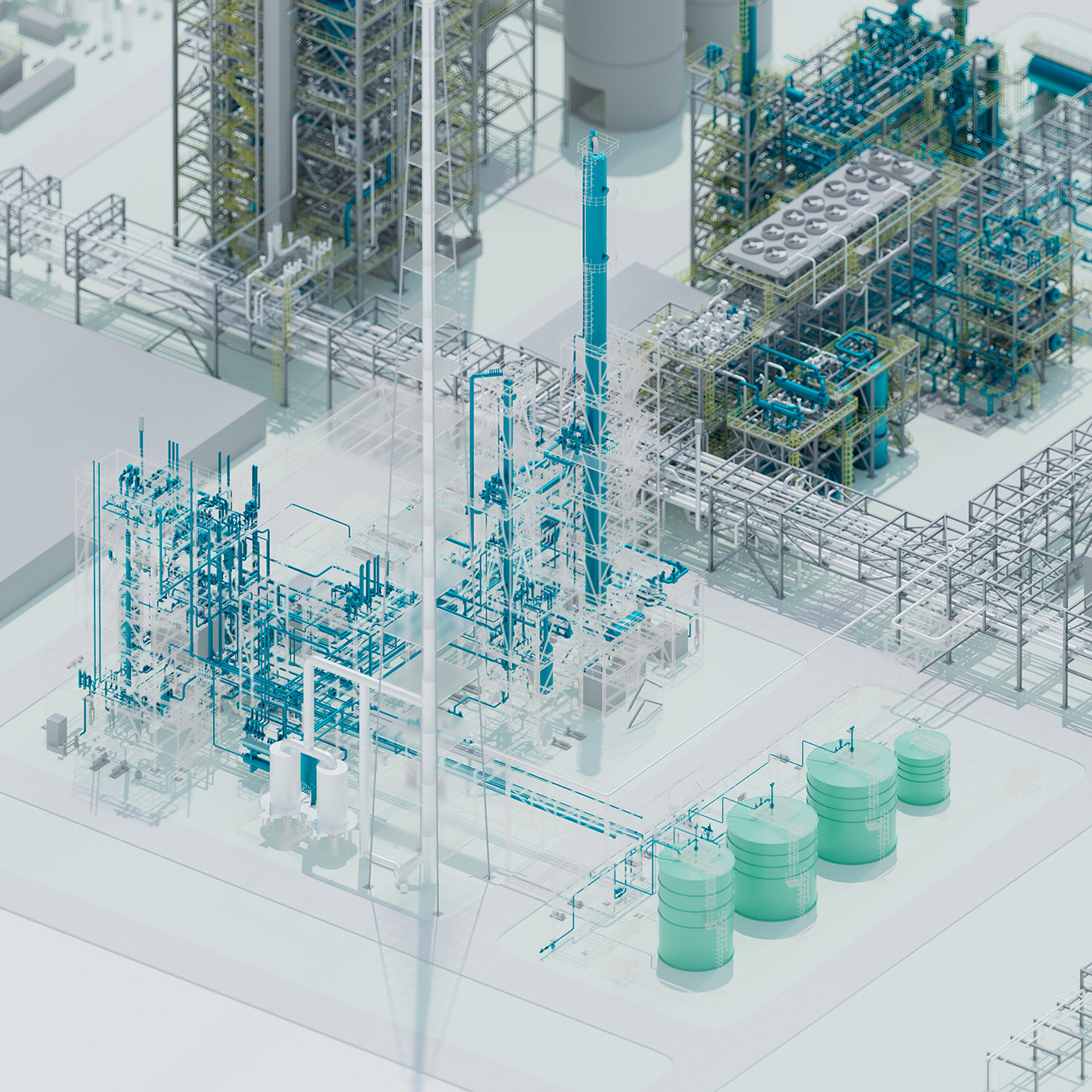

CO2 Polishing

Clears CO2 from all impurities for further usage.

Additional benefits of GIDARA Energy's approach are the supply of excess CO2 to local greenhouse horticulture, the recovery of solid residues used for making bio-composite cement filling, and minimizing the use of precious water resources. Before using CO2 in greenhouses, it must be cleaned from all impurities even smallest ones.

Advanced Methanol production facility

The methanol production facility represents a crucial component of the AMA, where the final step occurs. In this section the syngas is utilized to manufacture methanol, completing the process.

Methanol is a versitile building block and can be used to produce hydrocarbons and even aromatic systems that are the basis of several technologies related to gas to liquids. These include methanol-to-hydrocarbons, methanol to gasoline, methanol to olefins, and methanol to propylene.

The advanced methanol will be used for fuel blending and therefore meet governmental objectives to achieve CO2 emission reductions as defined in the Renewable Energy Directive II and translated into national legislation. The produced renewable fuel will replace fossil-based fuels, creating significant carbon savings.

Behind-the-scenes

Research and development and funny moments :)

Molecular view, visual research.

Beauty of Houdini node structure.

Thank you!

Production: avrb.studio

Creative Director: Salva Mehtash

Art-Director: Alexandr Vorobiov

Procedural modeling: Sergei Kharchuk

3D Generalist: Alexandr Vorobiov

Software: Houdini Sidefx + Redshift