A good family friend whet my interest in leatherworking one day after mentioning how he had made his own pair of leather shoes. I always enjoy learning new skills, so I decided to join the next time they went to the leather wholesale. The next thing I knew, I had met a lovely and talented group of people who were eager to share their knowledge and experiences in the craft. I knew I had to take on a project to help me learn more about the trade. I had always wanted a briefcase, and although ambitious, I decided it would be the perfect project to allow me to deeply dive into the world of leatherwork.

Images from etsy.com

Having no knowledge of how to make a briefcase, I spent a lot of time on Etsy looking at briefcase designs. In my mind, I would try to visually reverse-engineer the product. From this process I was able to learn a lot about how to make a briefcase, such as how a bag is put together, what materials and fasteners are involved, and what stitching techniques to explore. The process also raised many questions I didn't have the answer to, which I could further research.

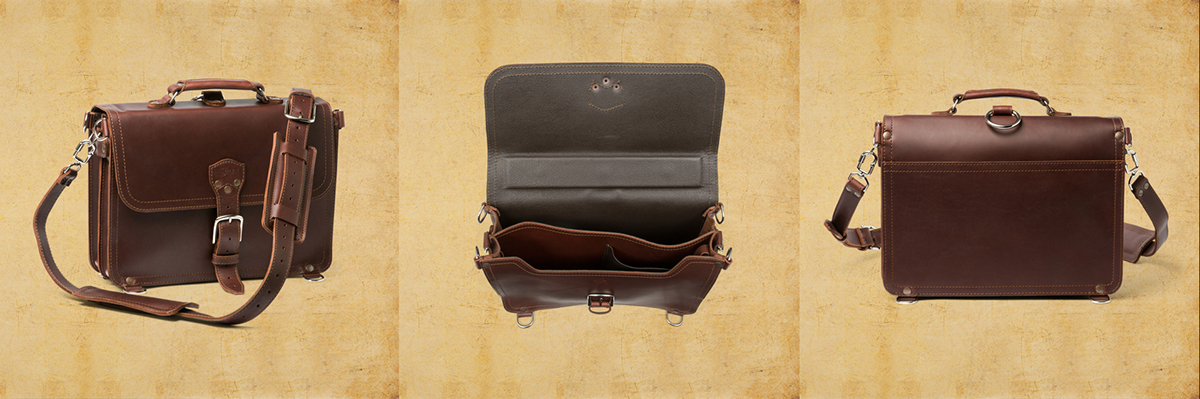

I eventually found out about the Saddleback Leather Company. From reading descriptions and reviews of their products, it became clear that they set an incredibly high standard for quality in their work. Their website thoroughly explained the techniques they used to achieve such a level of quality, such as enforcing the straps with nylon and riveting all the crucial joint locations. These details became standard for my own project. Their site also contained detailed descriptions for each product, such as dimensions, leather type, and leather thickness. With these details, I had enough information to start planning out my own design.

Images from saddlebackleather.com

I started by looking at what I needed: a briefcase that looked formal and could be taken to interviews and meetings, yet was functional enough to be used on a daily basis. It had to hold my laptop, charger, notebook, a novel, notepad or binder, pens, and snacks. The dimensions of these products drove the overall shape of the bag.

I sized the laptop slot to snugly fit my macbook. The main pocket was thick enough to fit a binder and large novel, wide enough to fit a notepad, and tall enough so that a binder could be stood in it if necessary. The main pocket fit both my laptop charger and notebook with enough room for some granola bars.

I then made a 1:1 scale prototype of the bag out of poster paper. This ensured all of the dimensions fit together and also fit the items I had planned for. Stapling the layers together provided a good approximation of sewing the seams on a thick leather, which was another important measurement consideration. Once all the dimensions had been finalized, the prototype was deconstructed and the individual cutouts could be used as the templates for cutting the leather.

Since I was learning as I went along, it was important to be able to adjust the process or design on the spot. For example, I quickly realized that the uneven and flexible leather made cutting straight lines much more challenging than I had anticipated, forcing me to change the way I approached cutting the pieces.

After all the pieces had been cut, it was time to prepare for sewing it all together. Due to the thickness of the leather, every stitch must to be pre-stamped into the leather. The process is extremely tedious and ensuring that the punches were straight required a lot of attention to detail.

Stitching the bag together was another extremely detail-oriented process. The entire bag is hand-stitched, and each stitch requires you to pay attention to the order and orientation of the threading, as well as maintain a consistent tension. The entire bag required about 70 hours of sewing.

The project was a great learning experience for me. It was an opportunity to scratch the surface of a new craft, and every craft I'm able to learn helps expand my perspectives. I also enjoyed the feeling of empowerment from being able to create useful products that addressed my personal needs. I gained a deeper appreciation for the time, skill, and energy that goes into products such as this bag, and it has helped opened my eyes to the economic realities of making a living off of a craft. Finally, I've come away from this project with an introductory understanding of the design process and design requirements that make working with leather unique, which I'll be able to further build on in projects to come.

Recently, the folks over at Saddleback Leather released a great video on how to knock off their bags. Though satirical, it did an incredible job at highlighting the features in Saddleback's design and manufacturing process that lead to unparalled quality. Reflecting on my bag, many of the techniques they mentioned were ones I myself had taken, whether for financial reasons, feasibility reasons, or simply because I didn't know there was a better way to do it. The video was a great learning opportunity, and is a must-watch for anyone trying out the craft!