Project developed during the design course internship, in partnership with Mercur. The thumb abductor is made of 100% cotton fabric that covers rigid plates of thermoplastic material, molded directly into the patient's hand.

The purpose of the product is to make the user's hand as functional as possible, assisting in the function of the abductor thumb muscle, keeping the thumb extended, perpendicular to the hand.

The project adopted the Human-Centered Design methodology, following the steps Hear, Create and Deliver.

As a result of the workshops, personas were developed to guide the project.

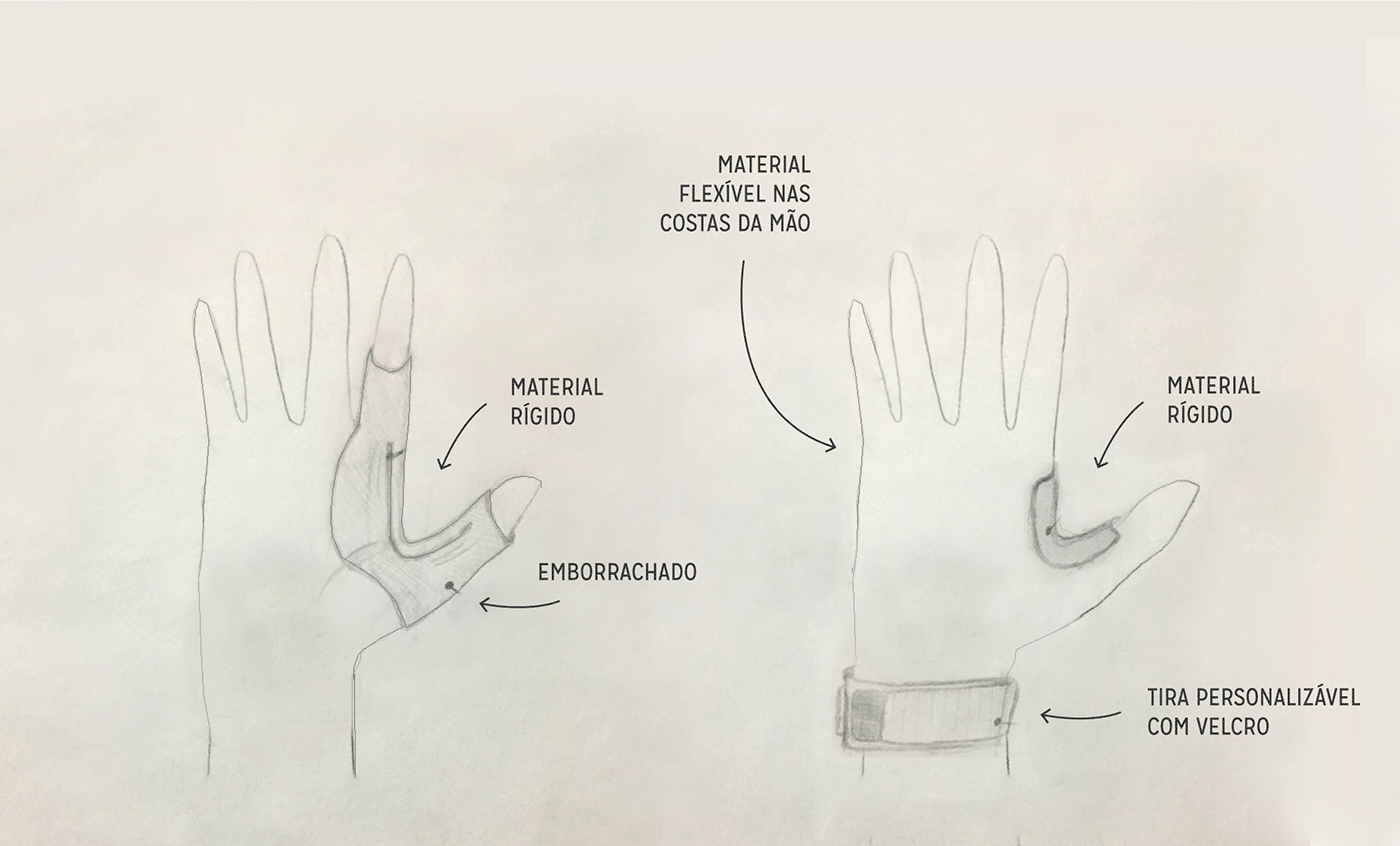

The requirements and restrictions for the project were also developed and from the co-creation activity, the generation of alternatives began.

..

;;

For this purpose, two rigid thermoplastic plates were used to guide the position of the thumb, covered in 100% cotton canvas fabric. On the wrist, the product is closed with velcro. Thermoplastic plates, when heated in water at a temperature of approximately 70ºC becomes malleable and can be molded directly into the patient's hand by a physiotherapist or occupational therapist. After a few minutes, the material cools, maintaining the desired mold. The cotton fabric used to cover the plates is soft, resistant, anti-allergic and comfortable. To manufacture the thumb abductor, the processes involve cutting and sewing the fabric and shaping the thermoplastic. The chosen alternative can be manufactured in different colors and sizes and is easy to clean, as the internal plates can be removed for washing.