This project was a co-development with SSAB, a company that transports (among others) steel plates through North America by rail. They used to secure their plates by shaping steel profiles (J-hooks) around the plates and secure them with all thread. Then they deform the thread by a hammer so the nuts don't get loose during transport. At arrival, the all thread needs to be grinded through. All very time consuming.

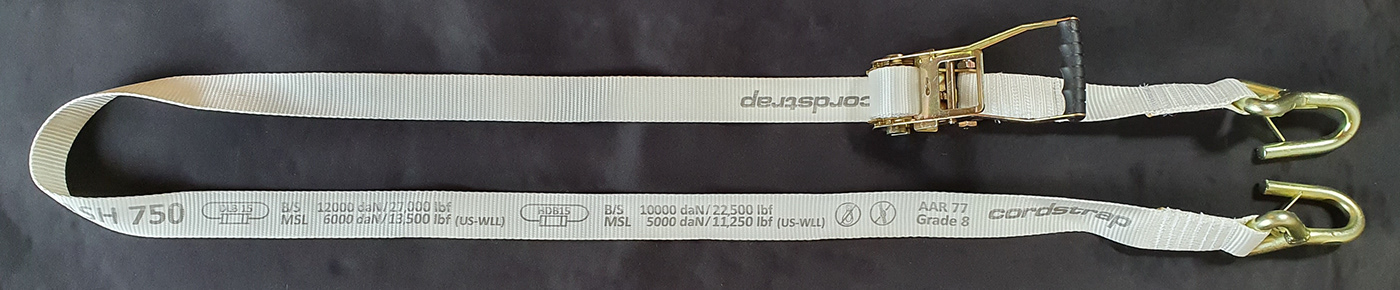

We developed a pre-assembled piece of lashing with hooks and ratchet, which can easily be snapped on the end of the J-hook and tightened by a single person. To cut costs we switched the ratchet for a buckle. This way the lashing is used in a system and we could also use a lighter type of lashing.

Pieces of steel are shaped around the steel plates.

With a pneumatic torque screw, they secure the plates by screwing the metal hooks together with a piece of all thread and nuts. The thread is than damaged so the screws can't twist of during transport.

When the steel plates arrive, the all threads are than cut off with a grinder.

Our first prototype exists out of a piece of webbing with sewn on snap-hooks and ratchet.

On the top you see the all thread solution. In the middle the first prototype with ratchet and on the bottom the final design. By replacing the ratchet by our buckle the costs went down.