Forklift concepts

incooporation with IVT international magazine

The Orpela Centaur is a redesign for a telehandler with visibility improvements primarily in mind; smart and simple, the solution could be produced immediately.

At the heart of the concept is a seat that, together with the controls, rotates to either 90° or 180°. The cab is positioned on what is traditionally deemed to be the rear of a telehandler, so the initial setting of the seat – i.e. with the boom directly behind it – provides the operator with unparalleled views of the road or jobsite, both in front and to the sides, when in travel mode.

Moving the seat 90° greatly facilitates operations that require lots of moving backwards and forwards in a confined place, while the 180° (traditional) setting is better for the tricky work of loading and unloading. And because the cab is positioned right at the back, the view to the raised load is also a little easier on the neck.

With hub motors at each wheel powered by a generator, the Centaur is able to travel in either direction equally well. You can therefore choose to drive while carrying the load in front of you, as with a traditional telehandler or forklift, or drive it like an on-highway truck, with the load at the rear and the view ahead unencumbered.

Interior view

Orpela Gecko

There’s something in the way they look and move that makes many vehicles remind me of animals. For this challenge, I took inspiration from the gecko, which never fails to surprise me when climbing up the walls and even windows of my home.

I realised that if I could give this forklift feet like the gecko has, it would not be able to tip over! So I looked at how geckos manage this and tried to adapt their system into my forklift’s wheels. Each of the gecko’s feet contains half a million bristles, with each of those divided into 1,000 sections to create a Van der Waals force connection with the surface. Just one leg fixed to the surface could hold 30kg! The gecko has two joints in its big toe that it uses to release its leg. It bends its toe so that the angle between the bristles and surface changes and the Van der Waals force is reduced.

I realised that if I could give this forklift feet like the gecko has, it would not be able to tip over! So I looked at how geckos manage this and tried to adapt their system into my forklift’s wheels. Each of the gecko’s feet contains half a million bristles, with each of those divided into 1,000 sections to create a Van der Waals force connection with the surface. Just one leg fixed to the surface could hold 30kg! The gecko has two joints in its big toe that it uses to release its leg. It bends its toe so that the angle between the bristles and surface changes and the Van der Waals force is reduced.

Adapting a similar system into the wheel requires nanotechnology to create controllable bristles. The control system delivers a specific electric flow to each bristle, governing when its hold is released. This saves energy during travel, as the fl ow is predominantly sent to the part of the wheel that is in contact with the ground – other bristles receive less and less fl ow the further away they are from the tangent point. The gecko wheel could be an attractive proposition for all kind of transportation, enlarging the hold on the road to avoid rolling over. It could also produce a lighter forklift due to a reduction in counterweight, so less energy is needed for operation, as well as shipping them around the world. These machines are safe and friendly for operators as well as the environment.

Because the idea for this concept stemmed from the gecko, I decided to give this forklift a sculpted body to reference the reptile’s dynamism. The body is built of evolving surfaces that create a feeling of movement, and are ‘tensed’ to deliver a more masculine look. The top and bottom sections are divided by a grey cover starting at the front and moving backwards while evolving its form beside the rear lights. These details and surfaces deliver innovative and desirable style and dynamism.

Because the idea for this concept stemmed from the gecko, I decided to give this forklift a sculpted body to reference the reptile’s dynamism. The body is built of evolving surfaces that create a feeling of movement, and are ‘tensed’ to deliver a more masculine look. The top and bottom sections are divided by a grey cover starting at the front and moving backwards while evolving its form beside the rear lights. These details and surfaces deliver innovative and desirable style and dynamism.

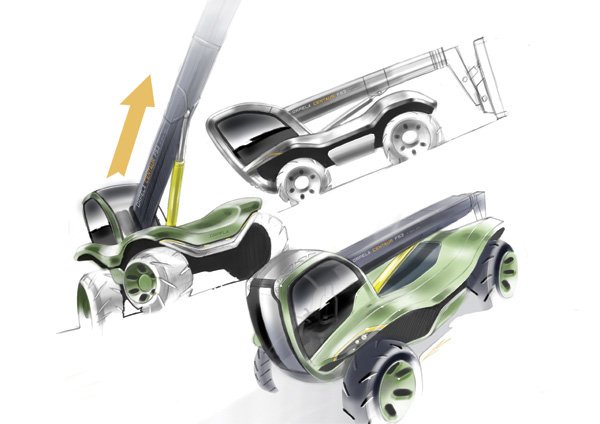

Orpela 612

“Although styled to be a desirable product, the Orpela 612 forklift concept was constructed from the user’s point of view. The mast is replaced with two telescopic arms borrowed from the crane world; these have been positioned behind the driver, and at 1,000mm in height, the structure does not interfere with the view to the rear. A strong bridge connects the telescopic arms and the forks, which could rise up to 5,000mm in five stages. Between the two telescopic arms, I positioned a lift that enables the cab to be raised up to 600mm. This would be employed when the load is bulky and would block the driver’s view, so he can elevate the cab to see over the obstruction. A camera system is positioned on the fork stopper, which allows the driver to better see the position of the load at high heights were the view is otherwise not accessible. A further improvement to the traditional forklift concept is the fork arrangement. Uniquely, these can collapse into the carriage, which greatly improves manoeuvrability. When driven this way, the forklift becomes much shorter, so after a load has been placed onto the shelf, the driver would not need to reverse as far – essentially the length of a standard fork less than with a standard truck. In terms of styling, the bridge that combines the telescopic arms is sculpted in some areas as a part of the whole body, but towards the fork it becomes more skeletal in appearance – a combination that gives the 612 a light but strong look. Proportionally, the machine is built so that the back is small and tight and the front is heavy and muscular, like a gorilla.”