As part of my Final major project during my BA Modelmaking degree at the Arts University Bournemouth, I created a stop motion puppet. The project was a collaboration with Bradley Mcnaughton a second year animation student who provided me with the turnarounds. He hopes to use the puppet as part of a pitch for his graduate film next year.

She is made from a steel and brass armature, with silicone cast head, hands and body.

As part of the project I spent three weeks working at Aardman animation studios in Bristol which was fantastic experience and taugh me a great deal about all aspects of puppet fabrication.

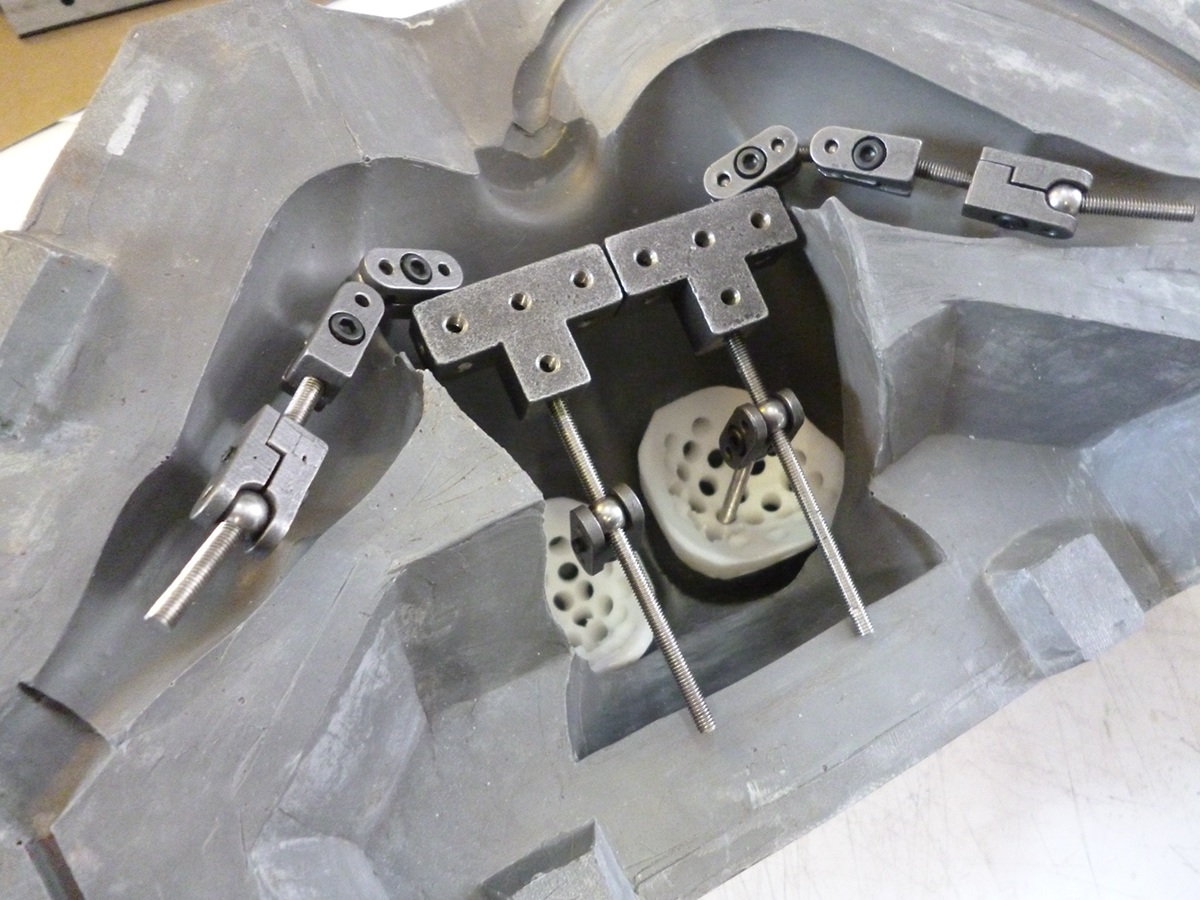

Possibly the most important part of stop motion puppet which is not visable on the outside is the internal armature which allows for the puppet to moved incrementally and produce the animation. Due to the lack of visable legs in the design of the puppet I had to devise a way of creating the illusion of movement. To solve this problem I creted a scissor jack mechanism armature which allows for the puppet to move up and down in a bobbing motion.

The scissor jack is then encased within a fiberglass shell that is then covered in fabric. The fibreglass is in two parts which allows for repairs to be made to the armature over time. Magnets inset into the shell allow for the two halfs to hold together and magnets in the base of the armature operate as an alternative to traditional tiedowns.

For the upper half of the puppet i decided to use ball and socket joints. Allthough i would have liked to make them myself I chose to buy them and save a lot of time.

With the brests being such an important feature of the character i decided they had to be animated so designed a way pair of implants which were connected to ball and socket joints attatched to the 'spines' of the puppet.

After having produced the sculptures of the character from plastaline i begun to design the moulds.

The molds had to be solid to cast the soft silicone material out. I chose to use a polyurathane fast cast pre mixed with aliminium powder. The aluminium powder reduces shrinkage and makes the mold more durable.

I chose to inject the silicone into the molds so had to incorporate this into the molds as well as plenty of risers to get the best cast possible.

I chose to cast the body with a softer silicone core and a firmer silicone skin. The process is quite detailed so Im just going to ut ba few pictures up for you to look at, but if you would like to know more about the process drop me a message and I would be happy to explain it.

I took direct inspiaration from my experience at Aardman when it came to designing the hand moulds and had great fun playing with the castings. Below are pictures of the process.