This project is in response to the 'Design Innovation In Plastics' competition brief

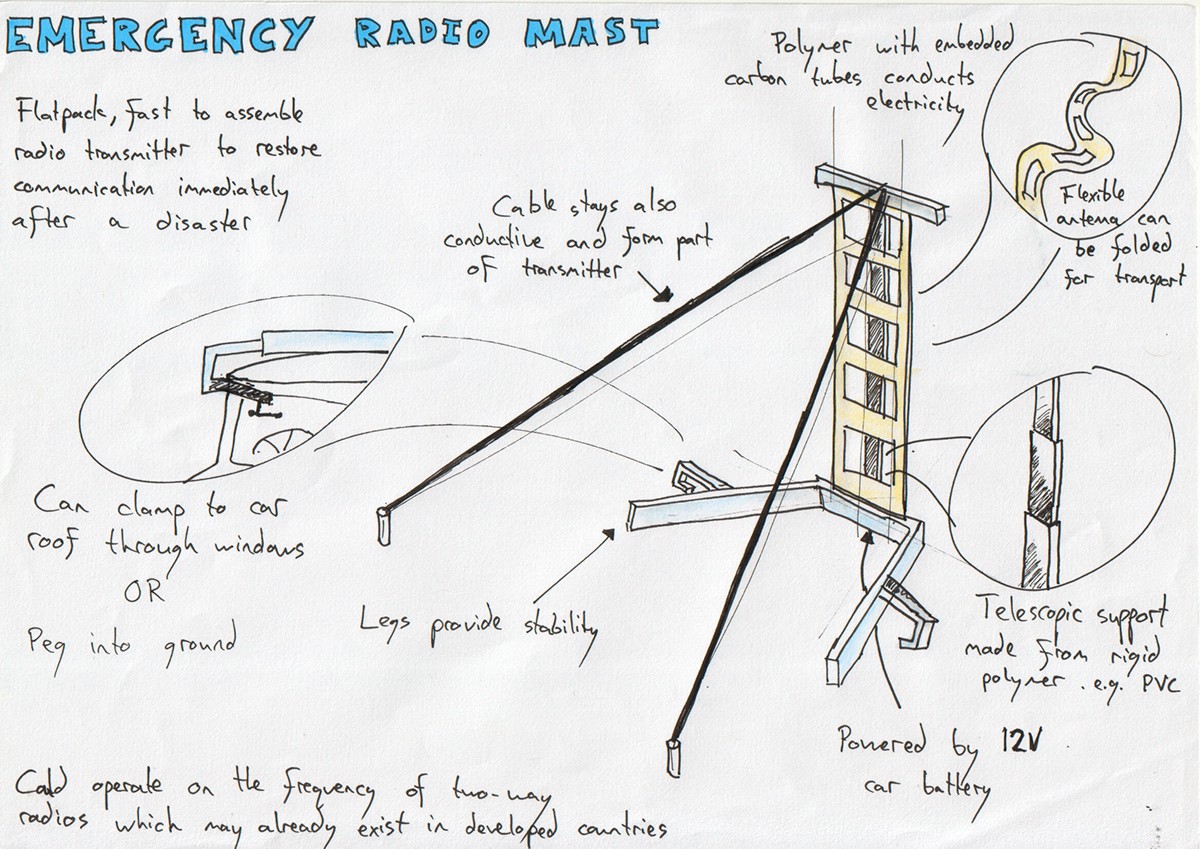

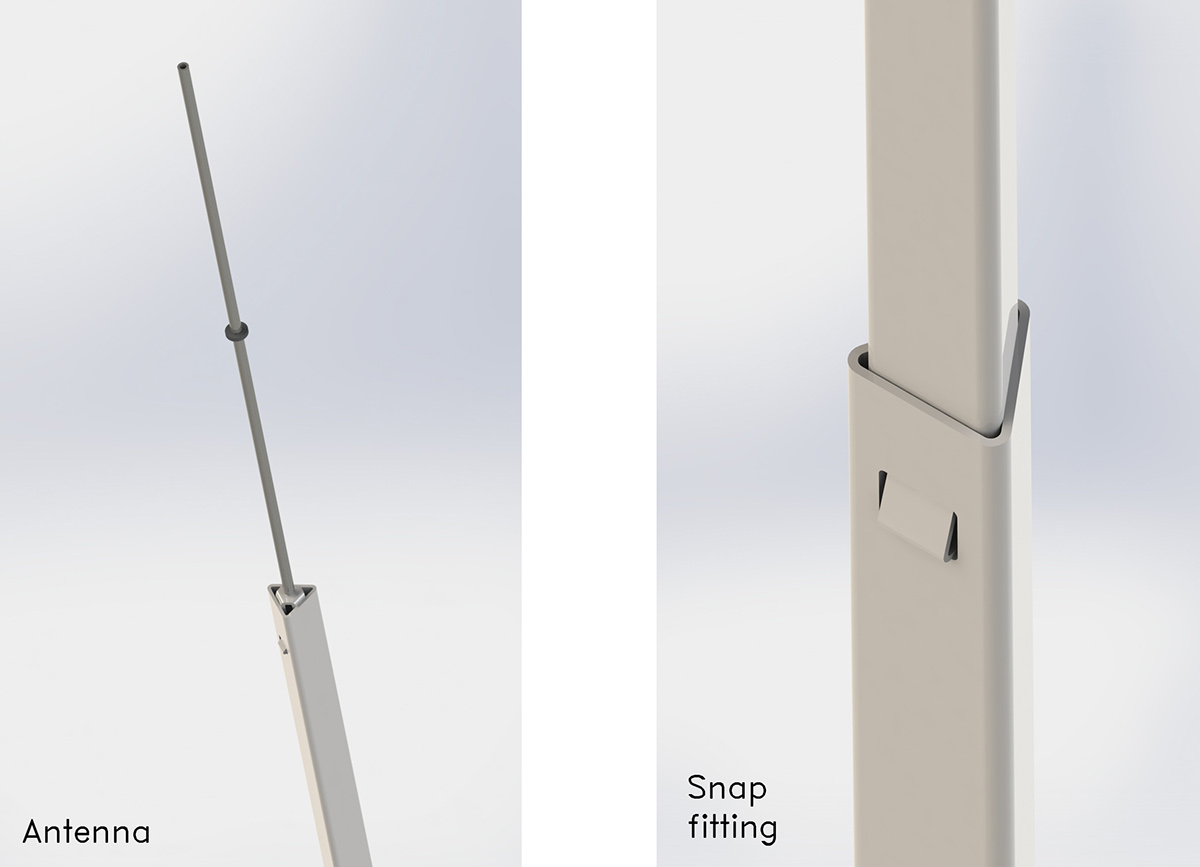

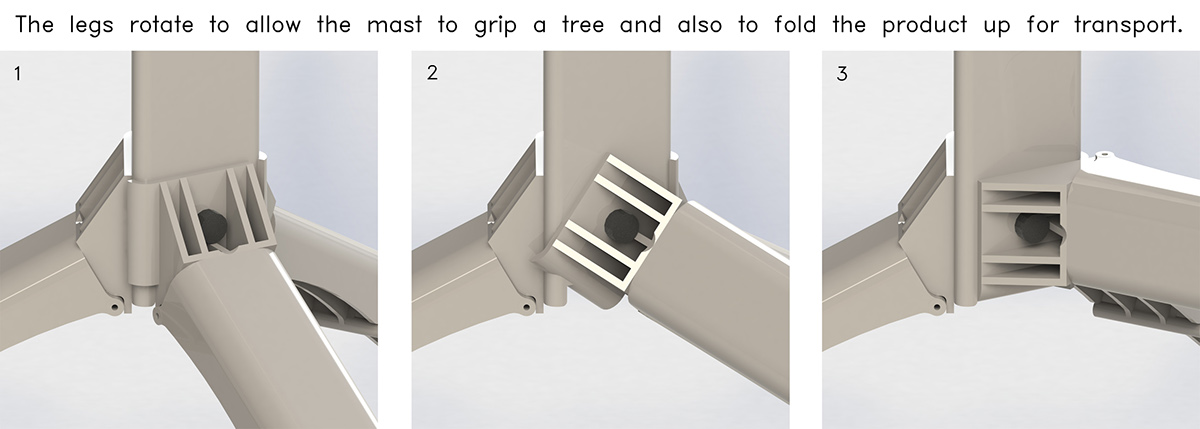

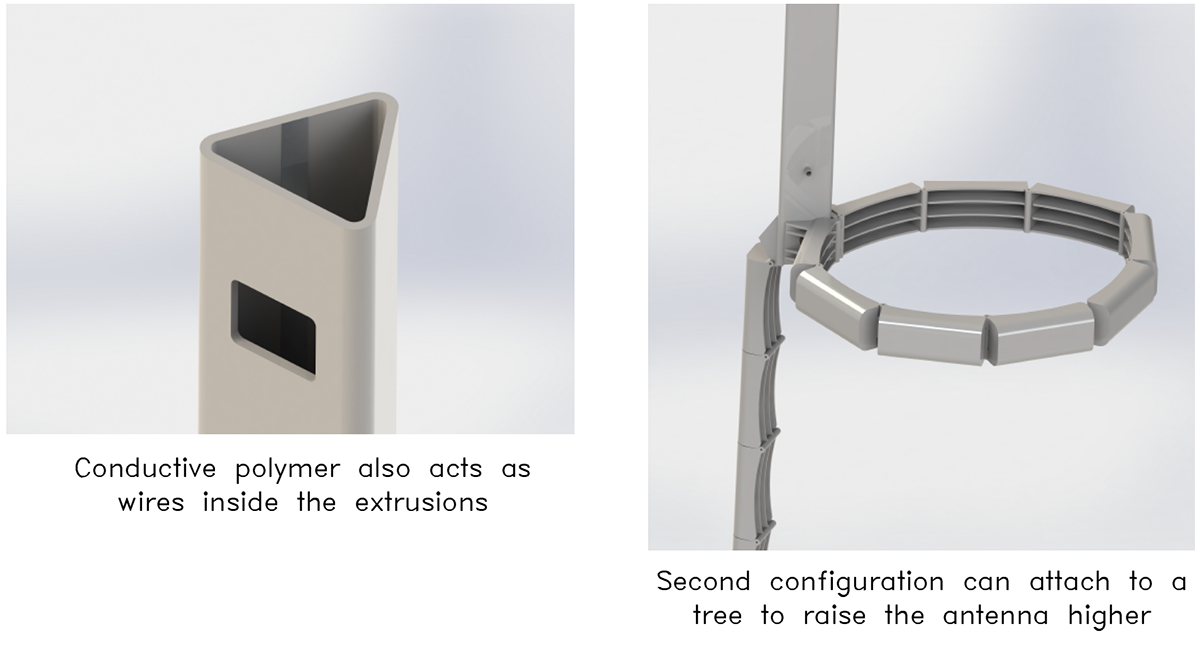

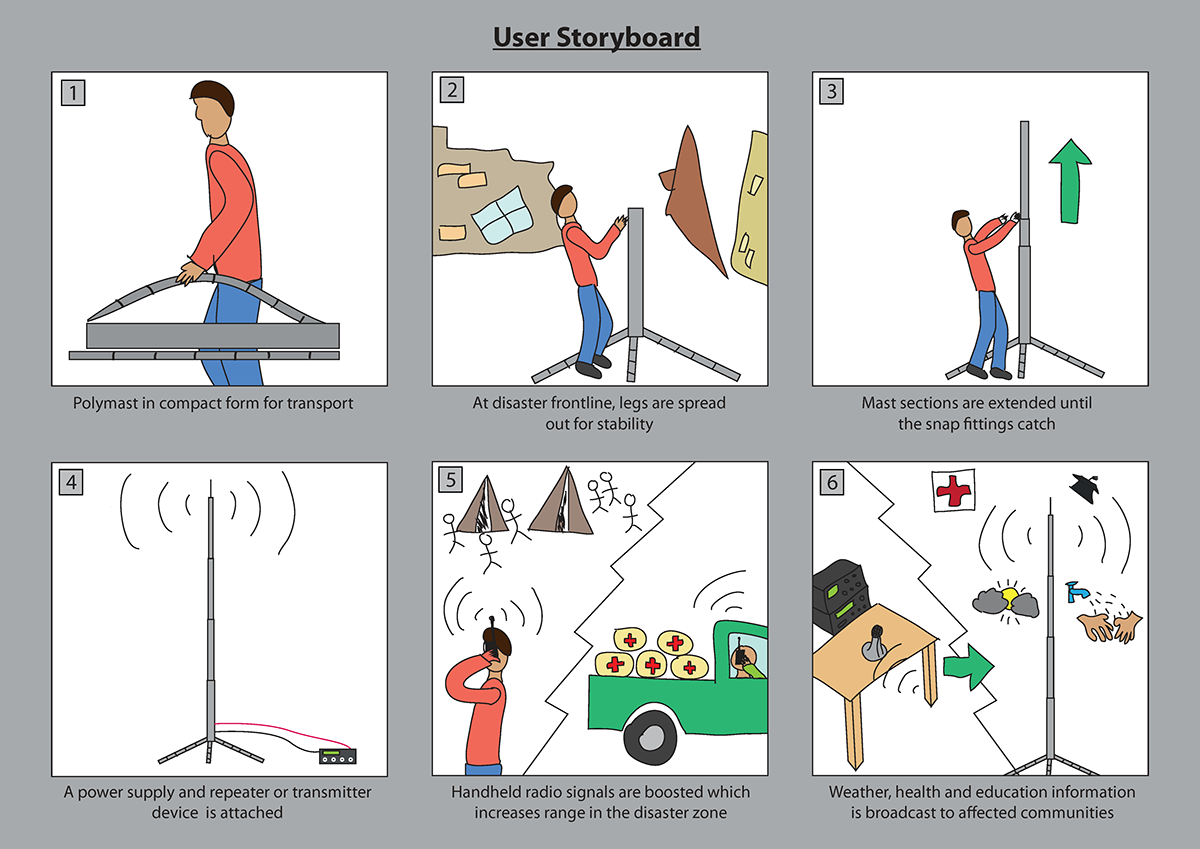

This portable radio mast can quickly facilitate communication after a disaster. It is entirely plastic and features an innovative use of 'inherently conductive polymers' in place of any metal to save weight and eliminate non-recyclable mixed materials.

[1]

At the beginning of this project I knew very little about how aid is provided in response to a world disaster. This made my initial research all the more crucial to designing a successful product. I began by producing moodboards on the subject and researching existing disaster aid products, of which there are many.

To structure my ideas I drew a mind map to compile types of disaster, human needs, possible polymers and means of providing aid. An important primary source was Northumbria's teaching staff for the Disaster Management course who have decades of frontline experience in disaster response.

To structure my ideas I drew a mind map to compile types of disaster, human needs, possible polymers and means of providing aid. An important primary source was Northumbria's teaching staff for the Disaster Management course who have decades of frontline experience in disaster response.

I generated a collection of concept ideas:

I chose to focus on establishing communication since it underpins the provision of help after a disaster.

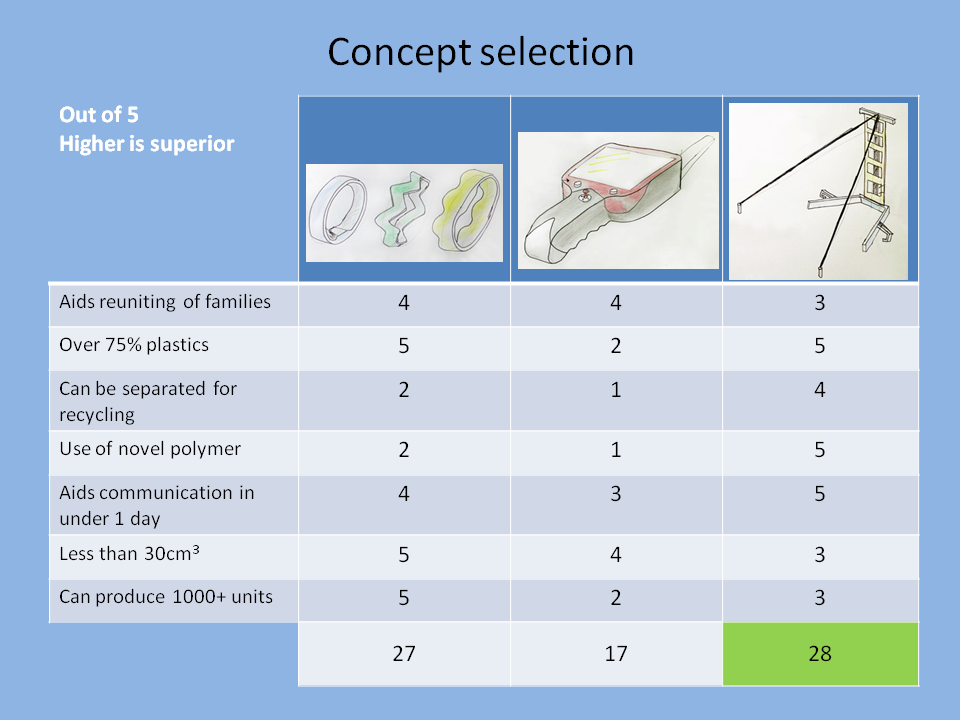

These are the 3 concepts I developed:

Based on the outcome of my concept selection table I developed the idea of a flat-pack radio antenna made with a conductive polymer. It scored well on the use of innovative plastics and the materials could be easily separated and recycled, both of which are key points in the design brief.

I produced a detailed specification referring to Stuart Pugh's methodology and set the known design constraints. For example after research I could calculate that the antenna section must begin at least 6.1m off the ground to achieve my specified 10 mile radio range.

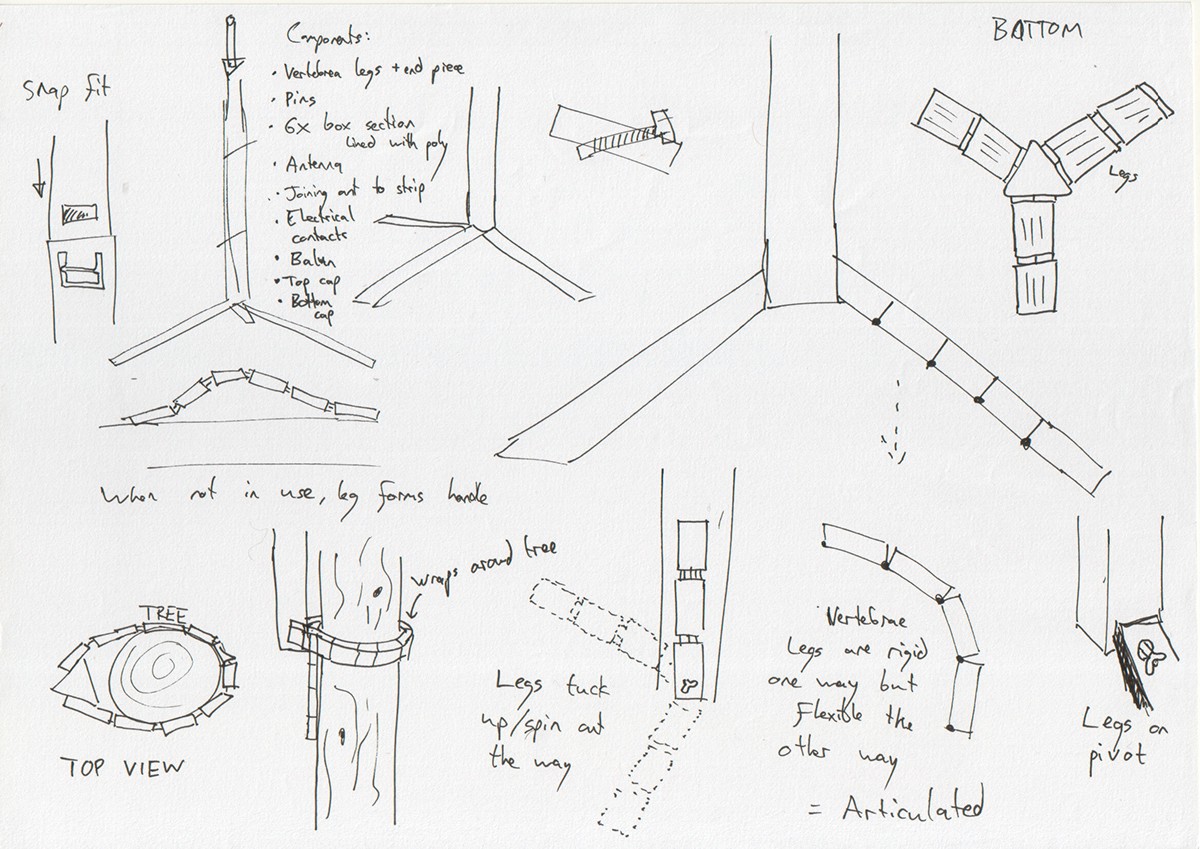

I moved onto detail design for the concept:

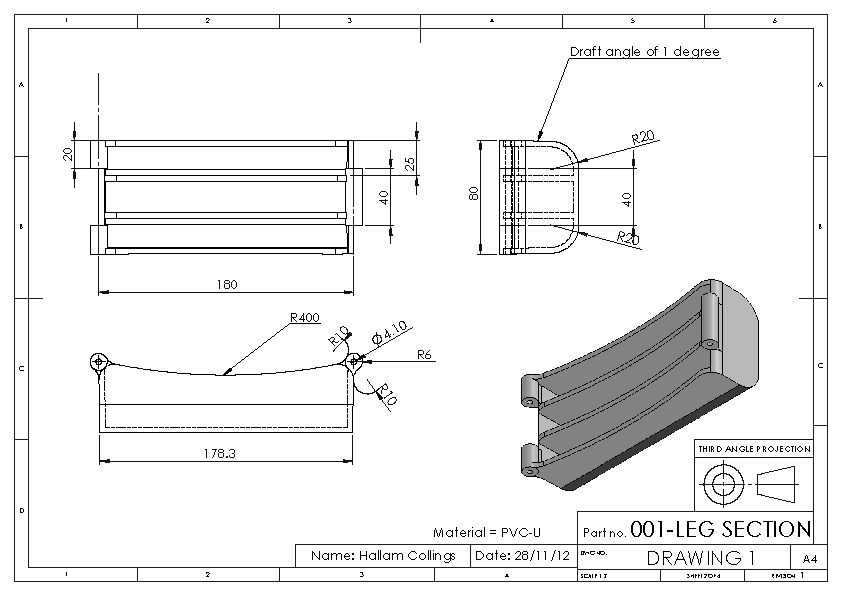

Here is the overall assembly drawing and a technical drawing for part of the leg:

I modelled my design in Solidworks CAD software and produced renders using Photoview 360:

Extensive research, patent searches and a literature review were performed on the viability of conductive polymers in commercial applications. I decided to specify the use of rigid PVC modified with Polyaniline which makes it conduct electricity. This is laid in tracks inside the triangular extrusions which are standard uPVC for its rigidity and corrosion resistant properties. The two materials would be co-extruded in a single process.

I performed a full analysis of the cost of production for my mast assembly. In summary, the materials, manufacture, tooling and labour costs totalled £26.44 per unit. The cost is minimal because the large parts are inexpensive extrusions, demonstrating my awareness of Design for Manufacture principles.

[1] Original image source: Mike Eliott https://www.globalgiving.org/photo/PIC13756/refugee-camp-in-sudan-credit-mike-eliott/