MINIU - Episode1

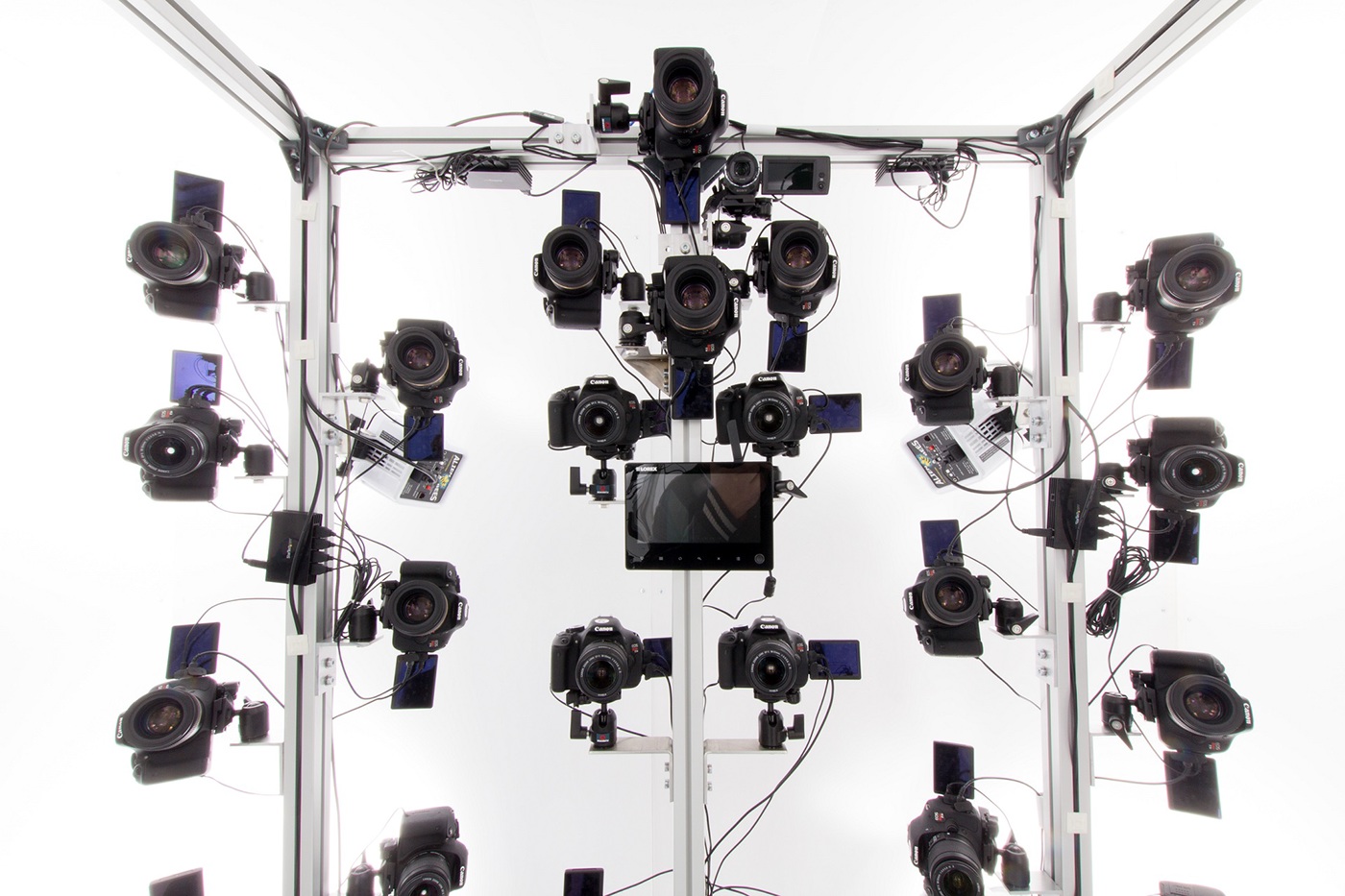

3D Scanning Photogrammetry Booth

My involvement in iMakr 3D scanning booth consists of two main stages: Construction and Operation. In the contraction phase, my role was to research and technical design support to senior engineer: Completion of full detailed production drawings including full material specifications. Operation phase where I use the software package called Agisoft that performs photogrammetric processing of digital images and generates 3D spatial data.

The Scanning Rig we constructed consisted of 48x Canon DSLR’s mounted on a custom aluminum extrusion frame. The modular design meant we could assemble and disassemble the rig within a short space of time in addition it also allowed us to make further modifications with ease. All the cameras in this set up are linked to a single trigger; this trigger allows an operator to activate all the cameras instantly capturing 48 images in one second. These Images are then processed using a software package called Agisoft , which compiles still images into a point cloud, and from this point cloud, a 3D mesh is created.

The Mini-You project involved the installation of a photogrammetry scanning booth at various stores in the UK including the iMakr store, Selfridges (London) and Harvey Nichols. This innovative scanning system captures real-time data, which can be used in the production for a miniature version of you. Once the person has been scanned the images are compiled inside Photoscan to create a raw obj scan file that can be edited inside Zbrush.

Rig in Operation

Processing of Photosets

Explanatory Video