I´ve written this section to cover a few of the bicycle projects I´ve done in the last years.

One of my favourite hobbies has always been bike riding, so when given the choice I tend to move in directions where I feel at home. Or at least a place where I have a starting point in terms of self encountered user - experiences. This makes for faster processes, as I feel that talking to people in the business is easier if I really know what they are talking about.

So as I ventured into some of the first personally chosen projects during my studies it was obvious that bicycles would be one of the first ones.

The Thorium / OX #1

The first project was called Hard Rocx Thorium, and later Concept OX, in my eagerness to give life to new products I usually name every project from the beginning, thus making the project come to life even before a line has been sketched. The goal ulimately adressed the making of a high end professional road bike concept in which detailing and realism became key features and not the common "total" out of the box thinking. I tended to believe it was more important to create something that might be made than just fancy visions that would never see the light of day. This would hopefully also bring me closer to the company I was approaching, giving them a foundation they could actually use. So the focus was put on components, customization, material, production and detailing aesthetics rather than changing the "double diamond" configuration or making other radical changes to the frame geometry itself. After all Hard Rocx already had a geometric base fully suited and well tested for riders, so this geometry was implemented directly without hesitation. Also the decition to go full-scale on this new road frame, was a bold move, but something I was longing to do, to really be able to show the style of my ne creature, and hopefully impress the gang at Hard Rocx.

The first project was called Hard Rocx Thorium, and later Concept OX, in my eagerness to give life to new products I usually name every project from the beginning, thus making the project come to life even before a line has been sketched. The goal ulimately adressed the making of a high end professional road bike concept in which detailing and realism became key features and not the common "total" out of the box thinking. I tended to believe it was more important to create something that might be made than just fancy visions that would never see the light of day. This would hopefully also bring me closer to the company I was approaching, giving them a foundation they could actually use. So the focus was put on components, customization, material, production and detailing aesthetics rather than changing the "double diamond" configuration or making other radical changes to the frame geometry itself. After all Hard Rocx already had a geometric base fully suited and well tested for riders, so this geometry was implemented directly without hesitation. Also the decition to go full-scale on this new road frame, was a bold move, but something I was longing to do, to really be able to show the style of my ne creature, and hopefully impress the gang at Hard Rocx.

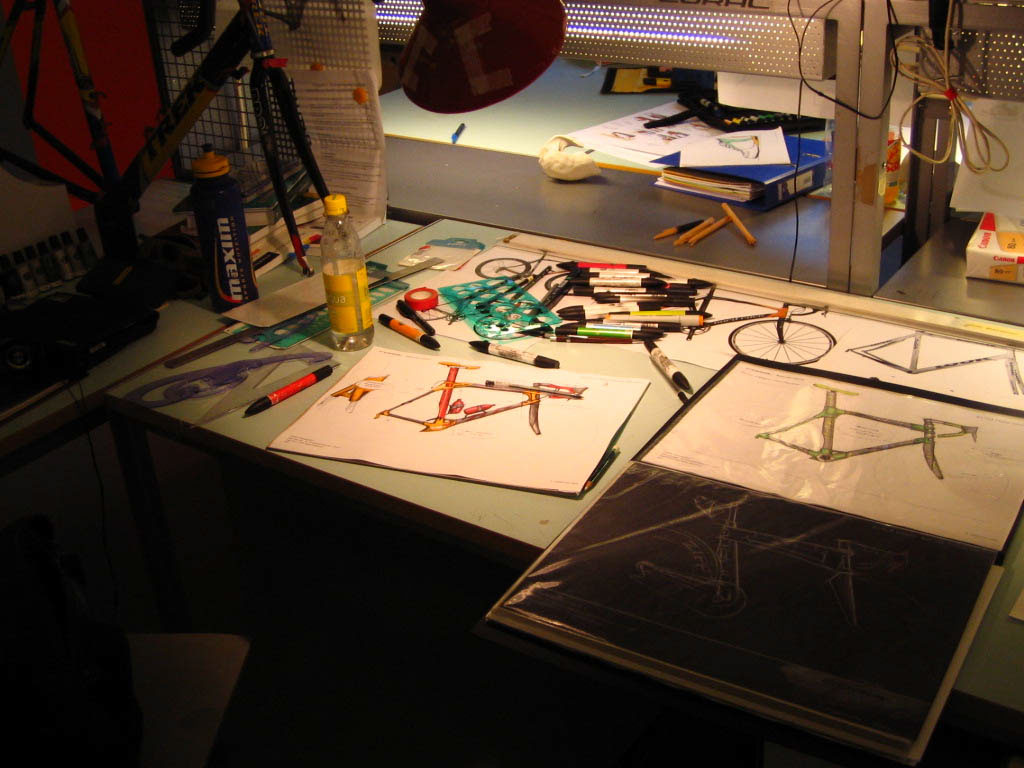

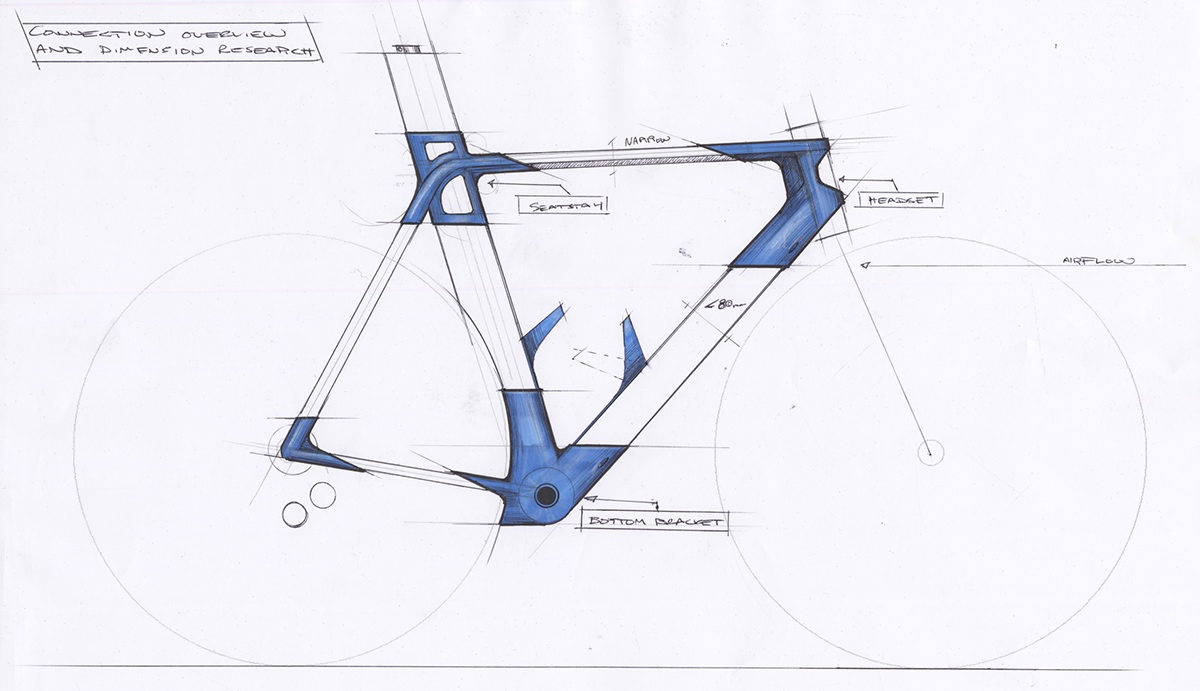

The whole project started out typically by researching markets, and locating the so called "state of things", and then base the sketching on these trends. Added to this the typical run - through of technical and functional ideas that come to mind as I boggled in how I could change the frame properties by adding minimal tooling cost in production.

I also fairly quickly "as usual" went full scale in my search for good proportions. In my mind there is simply no person in the world who can fully grasp proportion without experiencing it physically, looking at it and touching it. So getting there as soon as possible, at least helps me get to a state of control fairly quickly. In this project an old Trek frame I had was used as a base for large pieces of Auto Clay that were added to it, and shaved down to the wished look. A combination of the AERO style of the (then) new cervelo bikes and the Super Mechanic Styling of the Austrian BMC bikes was combined to make a strange hybrid of sorts that totally "hit" all the right buttons for me.

Added to my large collection of frame sketches, making good 2D Photoshop renderings of my new OX concept was highly appreciated by the Hard Rocx Team, who at first had been somewhat sceptical towards this young student, but now gradually were getting more involved in the project, ultimately sponsoring the cost of the prototype frame.

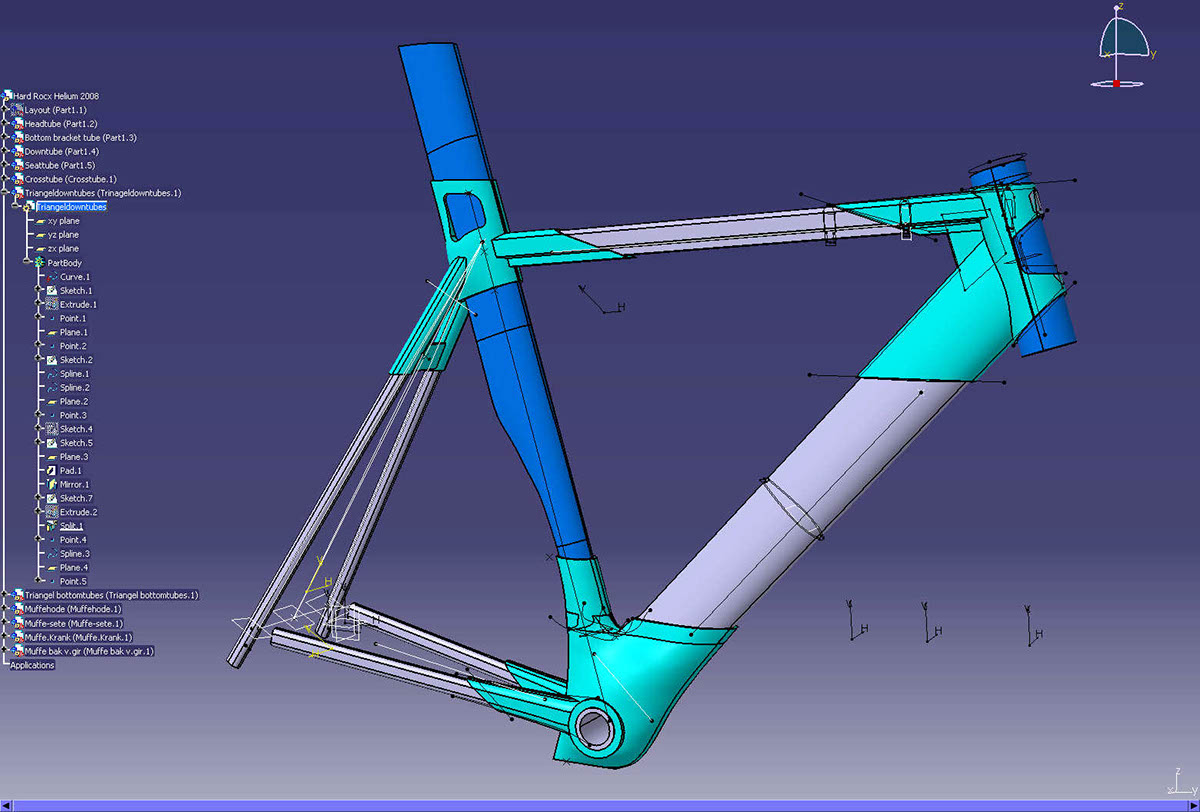

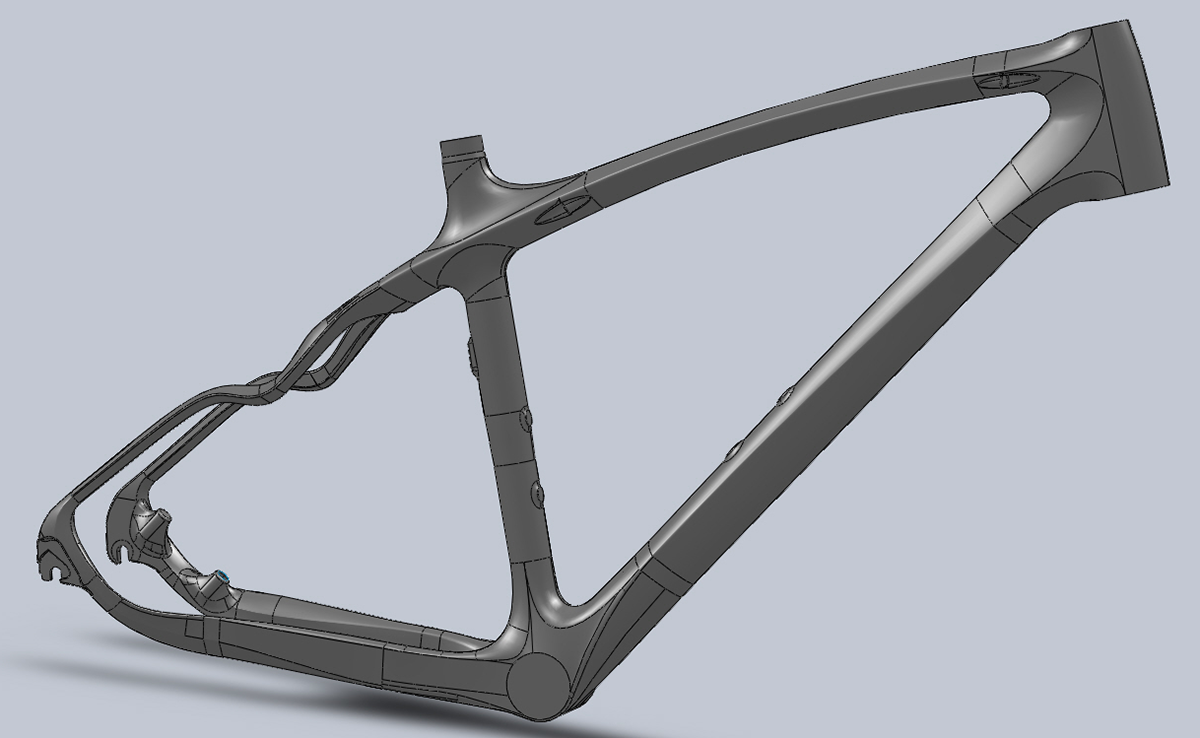

The construction itself started in the "nifty" engineering programme Catia V5, most commonly known as the most expencive CAD program to buy, thus only used by huge companies such as Airbus and BMW. Why we were learning it at AHO I do not know, all I knew was that I loved it. The functionality and possibilities felt at the time were just great, and making the "lugs" for my OX Road Bike, was one of the most challenging CAD assignments at the time, and gave me an opportunity to learn more.

The CAD model, swiftly was changed into a physical full scale model, by using the 3D printers at school to make the "lugs", tubing made from wire cutted foam (extruded shapes) and glass fiber armament on the surface. The frame was not going to be able to ride, but it would look roadable, and very suited for good photos.

Hard Rocx lended out great equipment for the model, sporting a Campa Record Set - Up and BORA carbon wheels, a FSA plasma steerer and bars and a tiny Selle Carbon Seat. Made for an awesome piece for the end presentation and student exhibition.

Pictures of the finished model was done by my good friend Peder Torget, and shows my vision in terms of aesthetics. Remembering this was back in 2006, a time when frames did not yet have a very "beefy" look. Well now they do, so I guess some of my assumptions were correct in this period.

Graphic Design, Paint , and Strategy

The Helium OX Project #2 (2011)

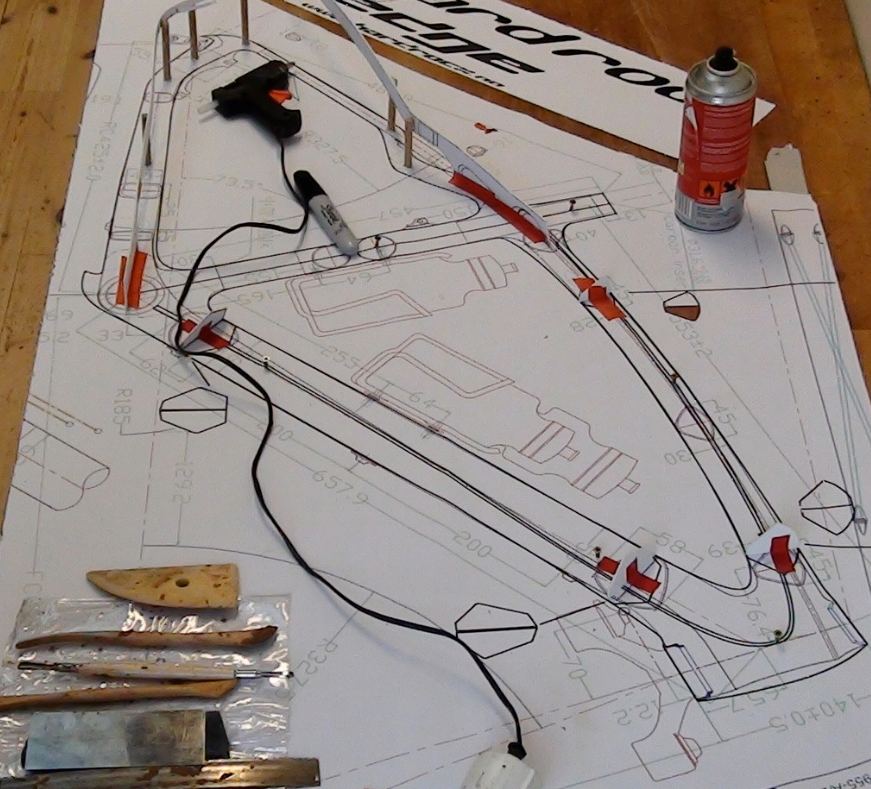

The prosess started as usual with several sketches on paper then brushed up in photoshop, and discussions within the Hard Rocx team. 3 key features were focused upon; working with the graphic strategy already worked on for several years, utilizing the carbon advantage in making the material move in some way, also making a very rigid and clear structure.

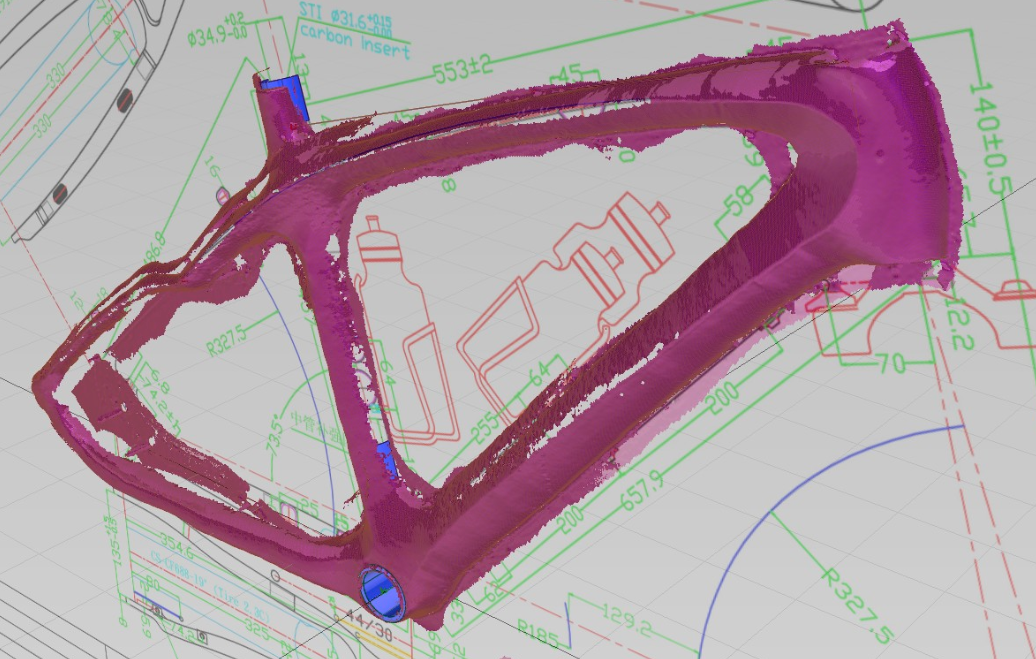

After Sketches and Car Cley we scanned the frame and brought it into the computer. Here all details were raffined.

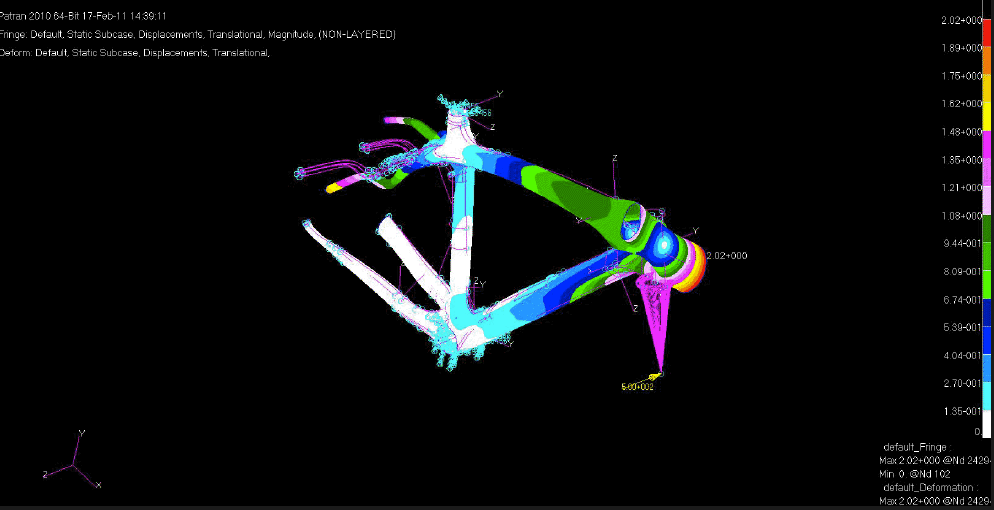

Several tests were performed to check performances on the frame and ensuring the best possible properties, The engineers at carbotech finished the details like cable trails, and crank infusion, the completed the tools for the carbon infusion process. 2 test frames were made and test benched.

One of the test frames above. And pictures of the first prototype shipped below.

Sketches for the OX graphic layout below. And the first test bike.

Below some of the finished 2012 OX frames, one 29" frame and some road bike concepts.