Abstract

1 in 400 children in the UK are affected by cerebral palsy. 30-40% of these cases are spastic diplegia and is the most common form of cerebral palsy. This project aims to utilise research within the field in order to produce a gait trainer to aid children with spastic diplegia.

Many new products on the market are walking aids rather than gait trainers. As a result some physiotherapists are becoming concerned about the physical development of children suffering from the condition. This design report aims to produce a product which both aids the development of the child’s gait whilst also enhancing the child’s ability to walk.

This project followed a design process which revolved heavily around the use of electronics and materials science but also made use of research into the field of education. The final design incorporated the use of electronics to allow the child develop their balance whilst walking. It also utilised several different mechanisms to compress the frame whilst not in use. Thus making it easier to transport and store.

The design has several unique features which were critical to the success of the product. These are namely the snap-fit shell, electrical feedback and the folding mechanism. As a result, the product could show a potential new route for the market to follow if the initial feedback received were to be replicated on a larger scale.

Many new products on the market are walking aids rather than gait trainers. As a result some physiotherapists are becoming concerned about the physical development of children suffering from the condition. This design report aims to produce a product which both aids the development of the child’s gait whilst also enhancing the child’s ability to walk.

This project followed a design process which revolved heavily around the use of electronics and materials science but also made use of research into the field of education. The final design incorporated the use of electronics to allow the child develop their balance whilst walking. It also utilised several different mechanisms to compress the frame whilst not in use. Thus making it easier to transport and store.

The design has several unique features which were critical to the success of the product. These are namely the snap-fit shell, electrical feedback and the folding mechanism. As a result, the product could show a potential new route for the market to follow if the initial feedback received were to be replicated on a larger scale.

Design Brief

The resulting product should be suitable for children aged between 4 and 10 who suffer from cerebral palsy. It should aid the development of the child’s gait whilst also allowing the user to participate in social gatherings and to gain independence.

The product should give either Level II children then chance to walk outside or Level III children the opportunity to travel indoors with only the help of the walking aid. The final design should be both sustainable and cost effective and this should be achieved through considerations taken during materials and manufacturing process selection.

The project as a whole must be completed by the 28th April 2014 but the report must be finished by 3rd April 2014. The entire project should take a total of 600 hours to complete, with 300 of these hours to be completed as a result of the project report. The prototype should cost no more than £300 to manufacture but this figure is flexible. The final design should be projected to cost less than £100 per unit when put into production.

The product should give either Level II children then chance to walk outside or Level III children the opportunity to travel indoors with only the help of the walking aid. The final design should be both sustainable and cost effective and this should be achieved through considerations taken during materials and manufacturing process selection.

The project as a whole must be completed by the 28th April 2014 but the report must be finished by 3rd April 2014. The entire project should take a total of 600 hours to complete, with 300 of these hours to be completed as a result of the project report. The prototype should cost no more than £300 to manufacture but this figure is flexible. The final design should be projected to cost less than £100 per unit when put into production.

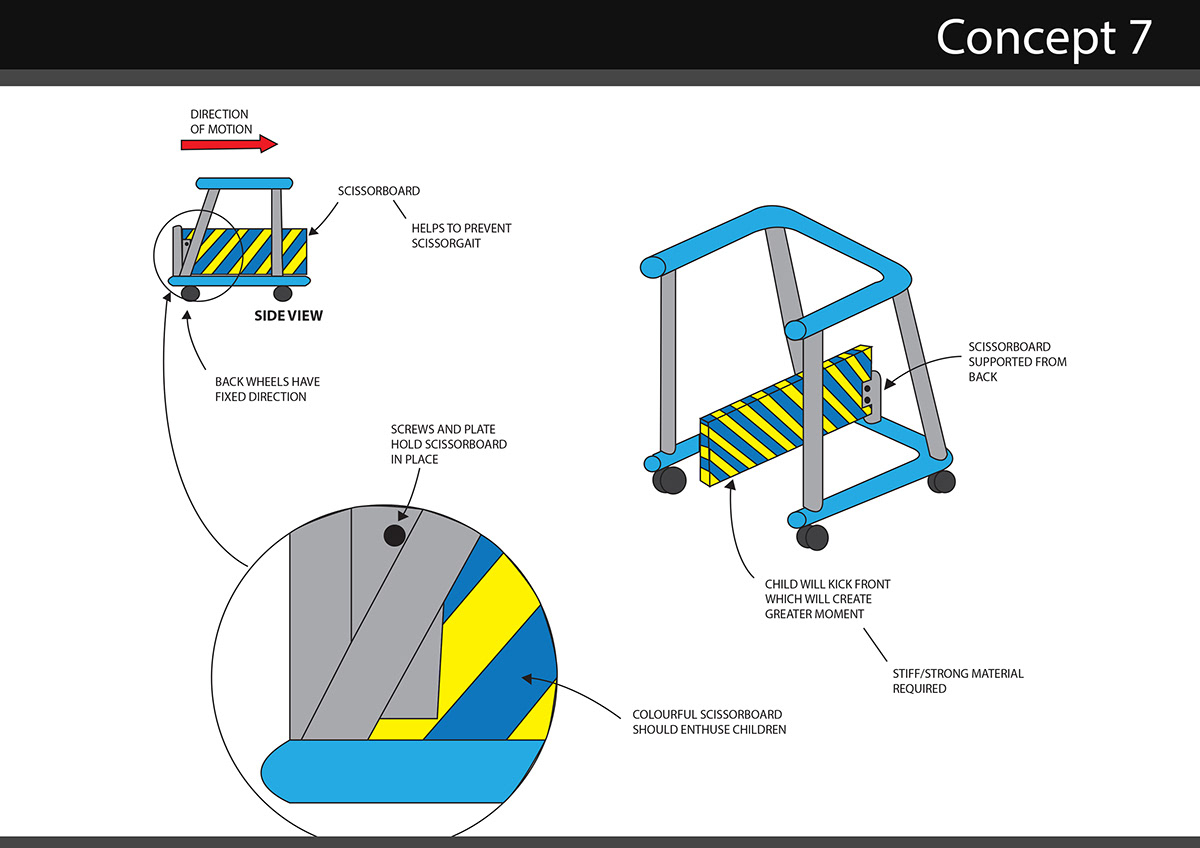

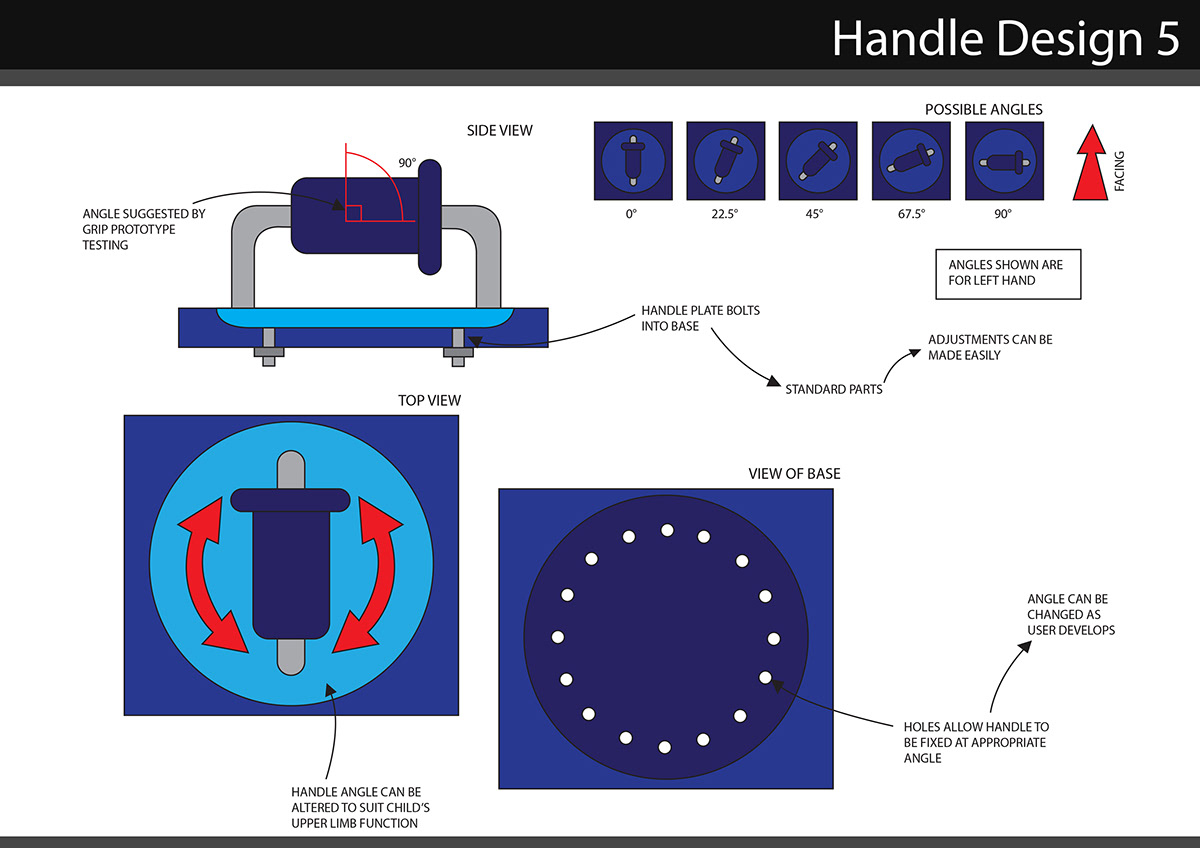

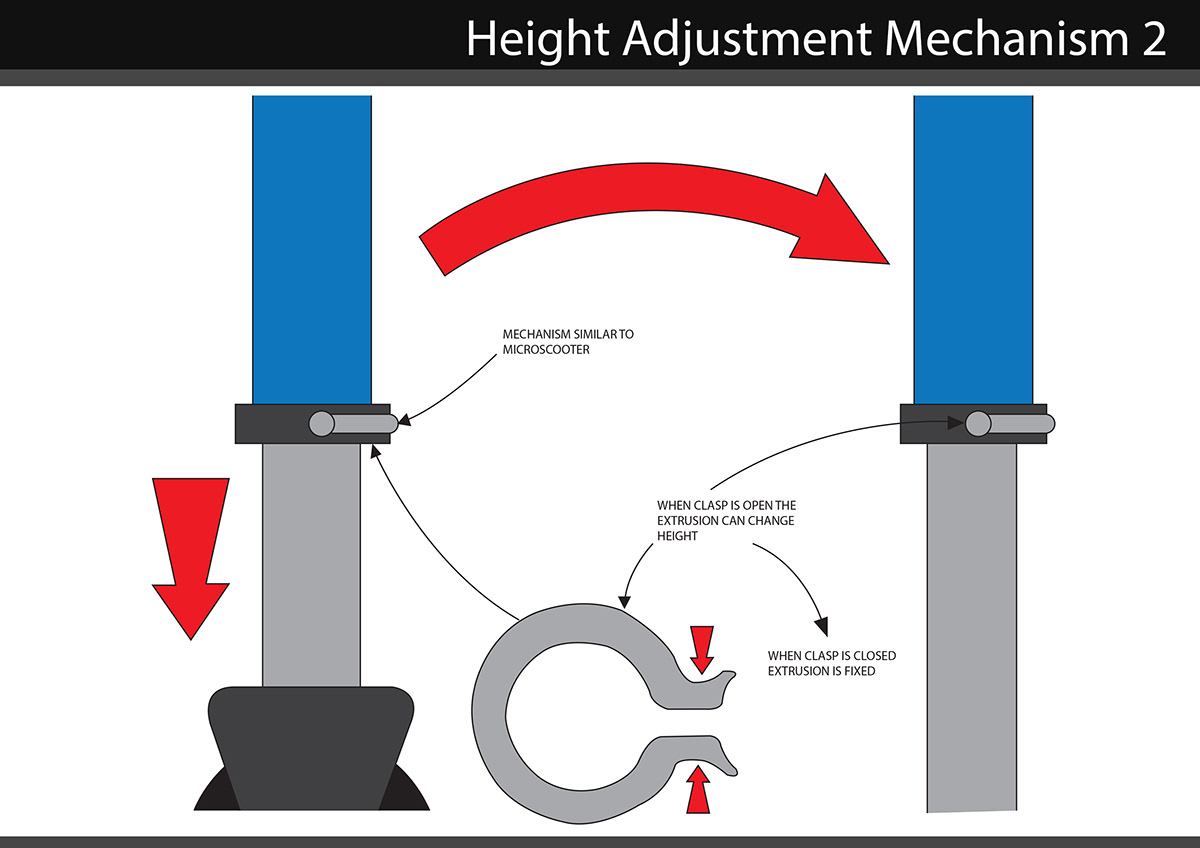

Concepts

Initial Design Development

CAD Prototyping

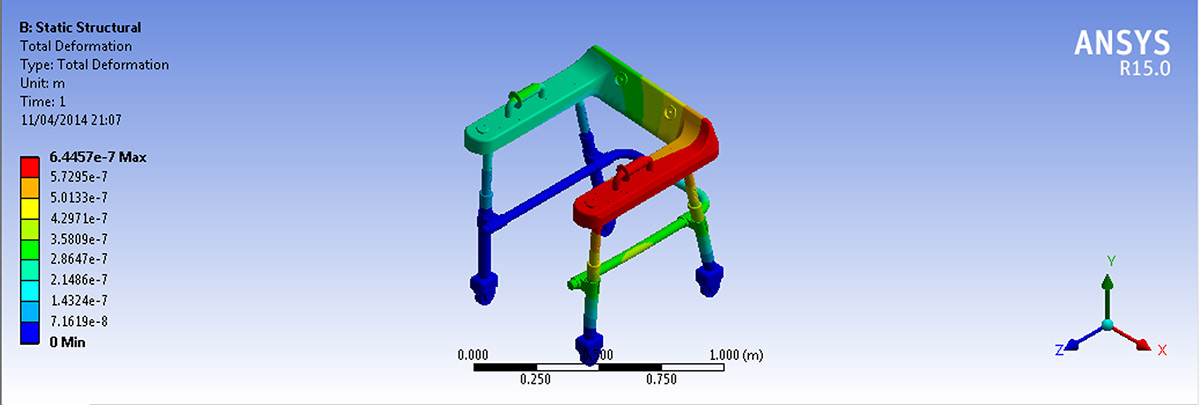

CAE Testing

Total Deformation (Uniform)

Normal Stress (Uniform)

Normal Elastic Strain (Uniform)

Maximum Shear Stress (Uniform)

Maximum Principal Stress (Uniform)

Maximum Principal Elastic Strain (Uniform)

X-axis Deformation (Uniform)

Maximum Principal Stress (412N to One Side of Frame)

Maximum Principal Elastic Strain (412N to One Side of Frame)

Total Deformation (412N to One Side of Frame)

Total Deformation (206N to One Side of the Shell)

Total Deformation (206N to One Side of the Frame)

Final Design Adjustments

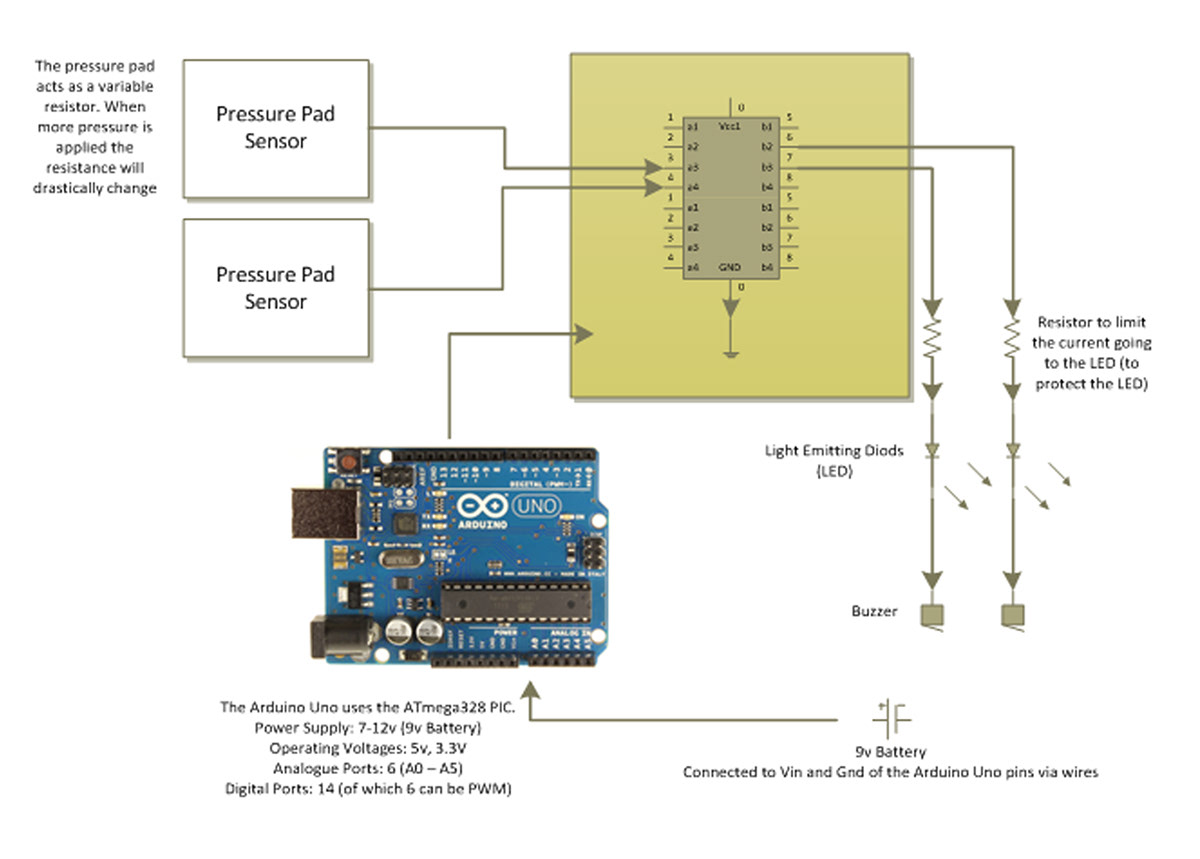

Electrical Prototyping

Physical Prototyping

Changes to Final Design

Visualisation of Folding Mechanism

Colour Scheme Added to Final Design

Castor Fittings Updated

Elbow Fittings Replace Bent Aluminium in Frame

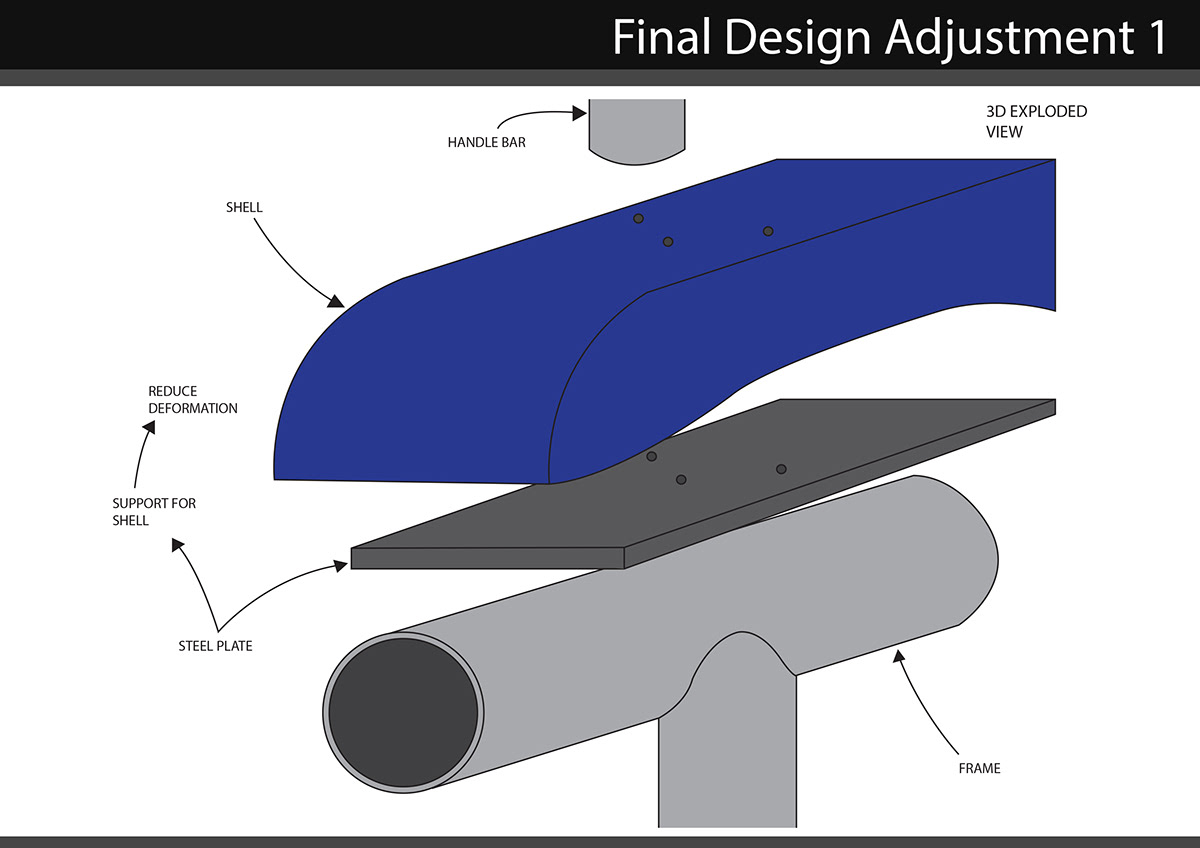

Steel Plate Added Below Hand Grip

Fewer Angled Cuts to Aluminium Extrusions

Hero Shots of Final Design

Exploded View of Final Design

Top View

Side View

Front View

Back View

Presentation Boards