Wedding Ring Design

Design and Production of my Wife's Wedding Ring

Design and Production of my Wife's Wedding Ring

With my fiance’ (now wife) and I both being designers, our tastes often overpower our budgets. A thorough hunt for the perfect ring left us unsatisified, with the top choices being not quite right and/or WAY out of our budget. We were not looking for a 5 carat monster ring, but something more reserved, but with a modern feel and clean detail.

After a little bit of research I determined that a custom ring design by us was the best solution. We found House of Diamonds who actually uses the same software I use to design products and furniture. They were willing to work with us by taking the 3d file I created and tweaking it for their production process. Karen and Gene were awesome in working with us, they gave us some guidelines and helped us arrive at the ring that will adorn my beautiful wife’s hand for our lives.

After a little bit of research I determined that a custom ring design by us was the best solution. We found House of Diamonds who actually uses the same software I use to design products and furniture. They were willing to work with us by taking the 3d file I created and tweaking it for their production process. Karen and Gene were awesome in working with us, they gave us some guidelines and helped us arrive at the ring that will adorn my beautiful wife’s hand for our lives.

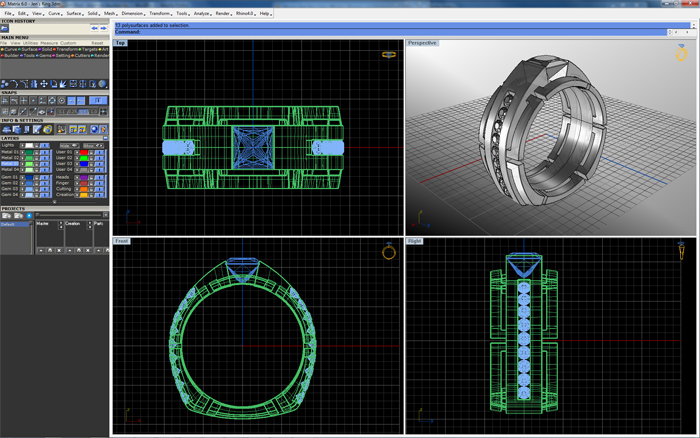

Screen shot of the ring at the end of the design process. My wife has small fingers, so I was a bit of a challenge to work at that scale. Proportion was essential, with every little change effecting the whole piece.

This is the resin casting that was used to make the final ring. The process is quite interesting and allows you to try the ring on before it is cast into gold.

A little be of detail on the process.

It is a prototyping machine, and there is a resin reservoir that a build platform lowers into. The resin is photo sensitive and turns from a liquid to a solid from high intensity light. The build platform raises by 25 micron thicknesses and each time it does, a different black and white bitmap picture of that thickness appears below the build platform. A very intense light flashes through it curing the white areas (similar to a photo negative). The process repeats for hours creating a very detailed resin model.

Then the resin model is put into an investment material (which is a plaster mold type material) that hardens around the resin model. The investment is then heated at high temperatures that further harden the investment while simultaneously burning out the resin model.

After the resin has been evacuated, we take the investment flask and use a self-contained centrifugal casting machine that precisely melts the metal and then throws it into the investment cavity (formerly occupied by the resin model). The result is a perfect metal replica of the resin model that will then begin to be filed, sanded, polished and stones will be set.

Each stone will have to have it’s own placement in the jewelry item.

Many stones that look the same have slight variances that have to be accounted for while building the finished piece. The jewelers have to be extremely skilled to remove as much metal as necessary to reach the desired finish, without removing too much metal which would compromise the design, finish, or integrity of the finished item.

A little be of detail on the process.

It is a prototyping machine, and there is a resin reservoir that a build platform lowers into. The resin is photo sensitive and turns from a liquid to a solid from high intensity light. The build platform raises by 25 micron thicknesses and each time it does, a different black and white bitmap picture of that thickness appears below the build platform. A very intense light flashes through it curing the white areas (similar to a photo negative). The process repeats for hours creating a very detailed resin model.

Then the resin model is put into an investment material (which is a plaster mold type material) that hardens around the resin model. The investment is then heated at high temperatures that further harden the investment while simultaneously burning out the resin model.

After the resin has been evacuated, we take the investment flask and use a self-contained centrifugal casting machine that precisely melts the metal and then throws it into the investment cavity (formerly occupied by the resin model). The result is a perfect metal replica of the resin model that will then begin to be filed, sanded, polished and stones will be set.

Each stone will have to have it’s own placement in the jewelry item.

Many stones that look the same have slight variances that have to be accounted for while building the finished piece. The jewelers have to be extremely skilled to remove as much metal as necessary to reach the desired finish, without removing too much metal which would compromise the design, finish, or integrity of the finished item.

Here is the rough casting of white gold.

The quality of the craftsmanship is impeccable, keeping details crisp and making the surface perfect.