Personalized medicine

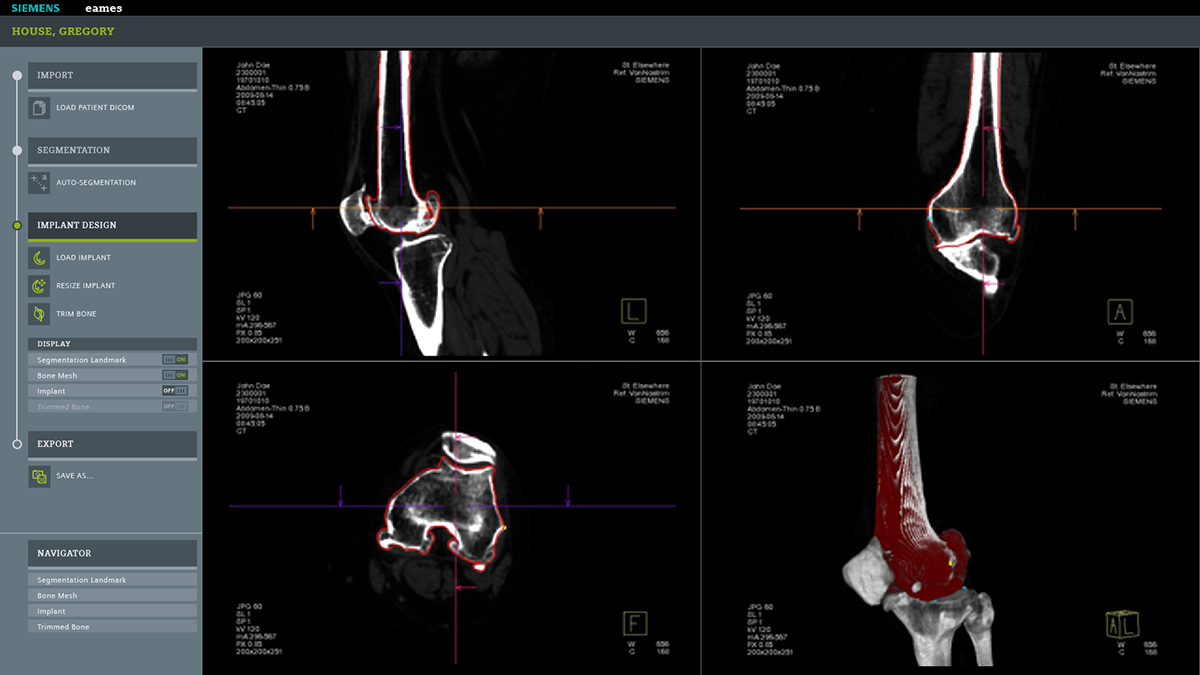

The image-to-implant process is to bring a solution based on an MRI or CT image of a patient's anatomy so that orthopedic implants can fit the patient, rather than "one-size" fit all. The project interface facilitated a main tool that allowed doctors and medical technicians to design and manufacture personalized medical devices without having to work in an complicated engineering process.

Enabling personalized solutions

Made to order

Conventional orthopedic medical procedures--such as in knee replacement--includes a set of scans in preparation of the operation, the surgeon orders a variety of pre-selected implant sizes and finally matches the final implant to the patient's anatomy during the operation. The approach of the personalized image-to-implant therapy takes advantage of custom-manufacturing based on the patient scans, even if a standard size range might have been selected at first. The difference is between the mass-produced product versus a custom product as a result of tailoring something mass-produced. The custom one is always going to have the better fit.

Workflows and roles

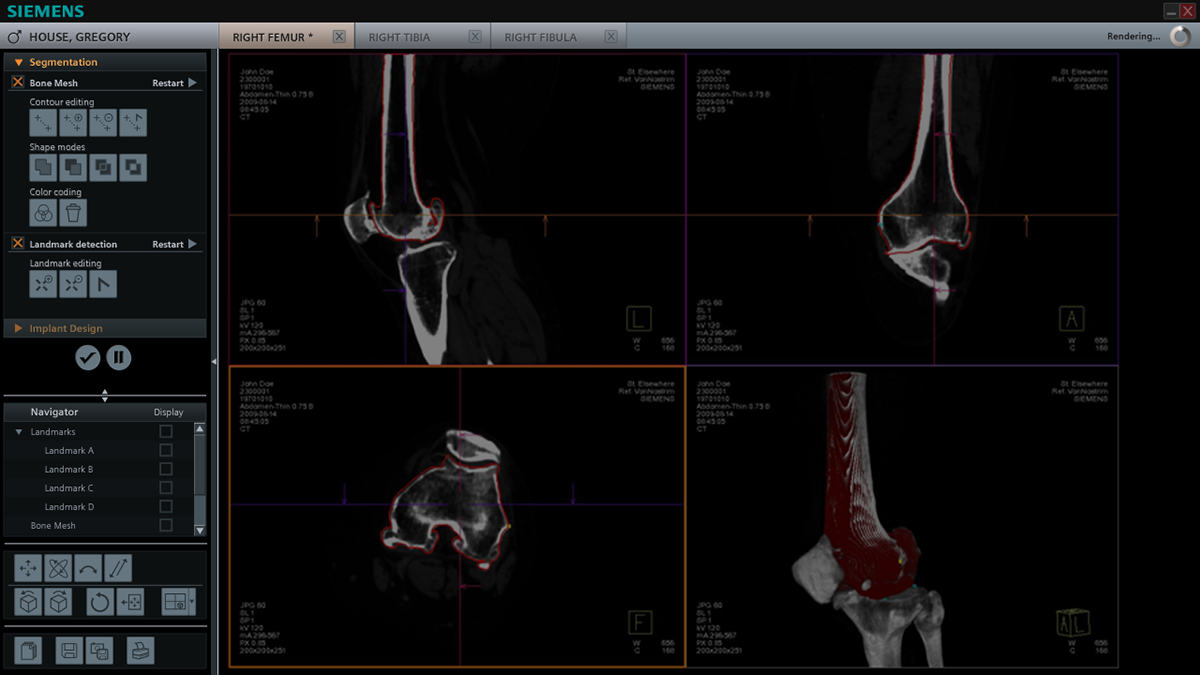

The entire process involved different medical professions integrated in a single workflow with different roles. We learned the focused needs of these different roles, such as the difference between the primary physician, surgeon, and medical technician, and part manufacturer so that we could provide the right tools for the most efficient process. Since these roles had different knowledge of medical and technical engineering expertise, the user interface needed to build around a focused workflow that would reduce error.

Process of making a custom implant was driven through a step-by-step workflow driver interface.

Automating and collaborating

The user interface took on a step-by-step workflow that walked through the image-to-implant process. While the software was able to automate some of the 3D modeling, the interface allowed for medical technicians to manually adjust and correct any details. Once they've completed a surgical plan proposal based on the joint replacement, it is reviewed by a surgeon. By integrating into a collaborative platform on a secure website, the coordination and process is speed up. The approved plan is then sent to the manufacturer in the format relevant to the industrial process for the part to be made. While this process chain passes through planning, design and manufacturing, it enables a good ending. Compared to traditional approaches, this benefits both patient and surgeons in less invasive and simplified surgical procedures, better planning, and shorter recovery time due to better fit.

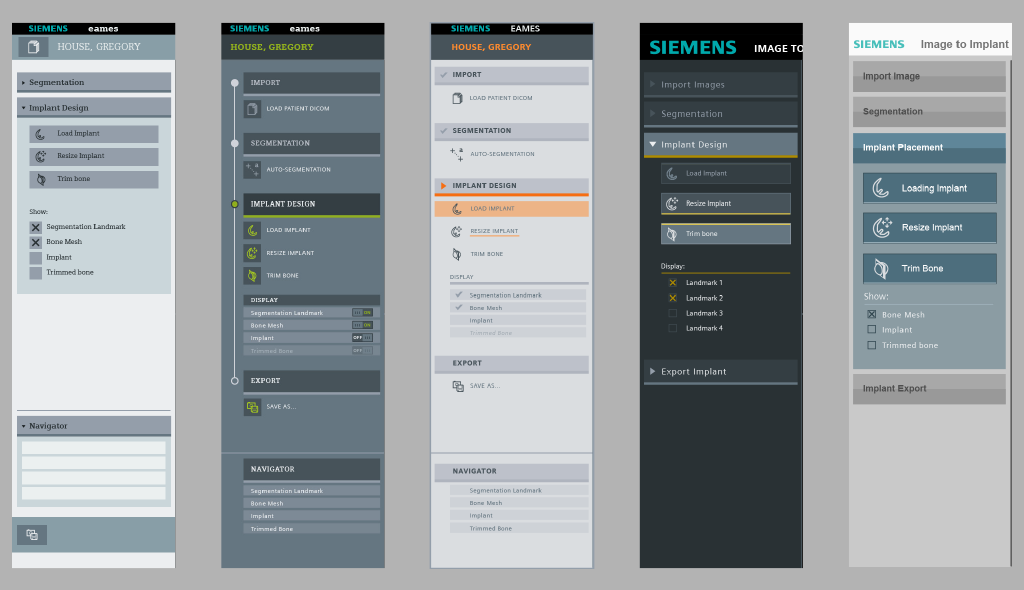

Look and feel visual explorations of the UI.

Different direction with visual affordance considered for possible touch input.

Image to implant process and service showcased at conference.